Case Studies

Case study: bhopal gas tragedy (1983-84).

Dr. Rhyddhi Chakraborty Programme Leader (Health and Social Care), London Churchill College, UK Email: [email protected]

What follows is a synopsis of the full article found in featured articles.

Please read the featured article Lesson from Bhopal Gas Tragedy (1983-84) By Dr. Rhyddhi Chakraborty Programme Leader (Health and Social Care), London Churchill College, UK describes in detail the elements of the Bhopal Gas Tragedy

Union Carbide India Limited (UCIL)

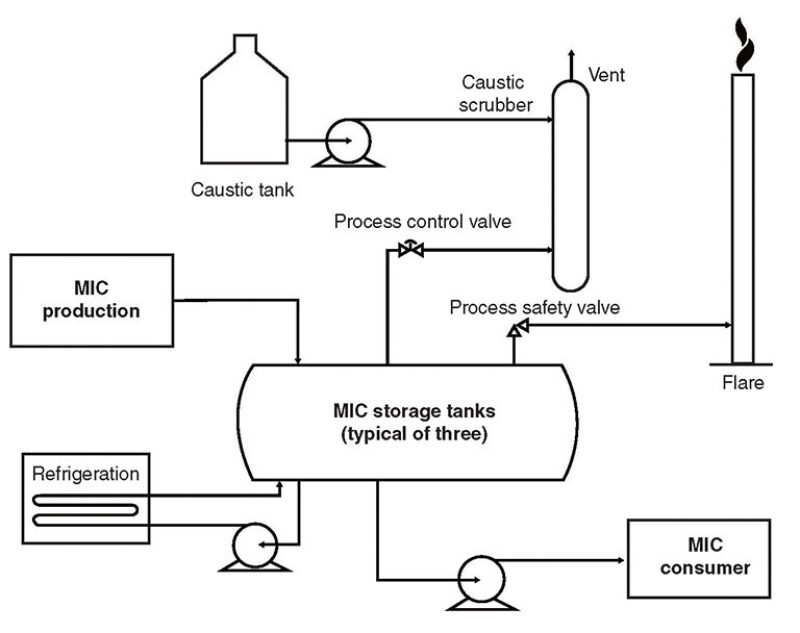

In 1970, in the North adjacent to the slums and railway station, a pesticide plant was set up by Union Carbide India Limited (UCIL). From late 1977, the plant started manufacturing Sevin (Carbaryl) by importing primary raw materials, viz. alpha-naphtol and methyl isocyanate (MIC) in stainless steel drums from the Union Carbide's MIC plant in USA. However, from early 1980, the Bhopal plant itself started manufacturing MIC using the know-how and basic designs supplied by Union Carbide Corporation, USA (UCC). The Bhopal UCIL facility housed three underground 68,000 liters liquid MIC storage tanks: E610, E611, and E619 and were claimed to ensure all safety from leakage.

Time Line of Occupational Hazards of the Union Carbide India Limited Plant Leading Before the Disaster

• 1976: Local trade unions complained of pollution within the plant. • 1980: A worker was reported to have accidentally been splashed with phosgene while carrying out a regular maintenance job of the plant's pipes. • 1982 (January): A phosgene leak exposed 24 workers, all of whom were admitted to a hospital. Investigation revealed that none of the workers had been ordered to wear protective masks. • 1982 (February): An MIC leak affected 18 workers. • 1982 (August): A chemical engineer came into contact with liquid MIC, resulting in burns over 30 percent of his body. • 1982 (October): In attempting to stop the leak, the MIC supervisor suffered severe chemical burns and two other workers were severely exposed to the gases. • 1983-1984: There were leaks of MIC, chlorine, monomethylamine, phosgene, and carbon tetrachloride, sometimes in combination.

In early December 1984, most of the Bhopal plant's MIC related safety systems were not functioning and many valves and lines were in poor condition. In addition, several vent gas scrubbers had been out of service as well as the steam boiler, intended to clean the pipes. For the major maintenance work, the MIC production and Sevin were stalled in Bhopal plant since Oct. 22, 1984 and major regular maintenance was ordered to be done during the weekdays’ day shifts.

The Sevin plant, after having been shut down for some time, had been started up again during November but was still running at far below normal capacity. To make the pesticide, carbon tetrachloride is mixed with methyl isocyanate (MIC) and alpha-naphthol, a coffee-colored powder that smells like mothballs. The methyl isocyanate, or MIC, was stored in the three partly buried tanks, each with a 15,000-gallon capacity.

During the late evening hours of December 2, 1984, whilst trying to unclog, water was believed to have entered a side pipe and into Tank E610 containing 42 tons of MIC that had been there since late October. Introduction of water into the tank began a runaway exothermic reaction, which was accelerated by contaminants, high ambient temperatures and other factors, such as the presence of iron from corroding non-stainless steel pipelines.

A Three Hour Time Line of the Disaster

December 3, 1984 12:40 am: A worker, while investigating a leak, stood on a concrete slab above three large, partly buried storage tanks holding the chemical MIC. The slab suddenly began to vibrate beneath him and he witnessed at least a 6 inche thick crack on the slab and heard a loud hissing sound. As he prepared to escape from the leaking gas, he saw gas shoot out of a tall stack connected to the tank, forming a white cloud that drifted over the plant and toward nearby neighborhoods where thousands of residents were sleeping. In short span of time, the leak went out of control.

December 3, 1984 12:45 am: The workers were aware of the enormity of the accident. They began to panic both because of the choking fumes, they said, and because of their realization that things were out of control; the concrete over the tanks cracked as MIC turned from liquid to gas and shot out the stack, forming a white cloud. Part of it hung over the factory, the rest began to drift toward the sleeping neighborhoods nearby.

December 3, 1984 12:50 am: The public siren briefly sounded and was quickly turned off, as per company procedure meant to avoid alarming the public around the factory over tiny leaks. Workers, meanwhile, evacuated the UCIL plant. The control room operator then turned on the vent gas scrubber, a device designed to neutralize escaping toxic gas. The scrubber had been under maintenance; the flow meter indicated there was no caustic soda flowing into the device. It was not clear to him whether there was actually no caustic soda in the system or whether the meter was broken. Broken gauges were not unusual at the factory. In fact, the gas was not being neutralized but was shooting out the vent scrubber stack and settling over the plant. December 3, 1984 1: 15- 1:30 am: At Bhopal’s 1,200-bed Hamidia Hospital, the first patient with eye trouble reported. Within five minutes, there were a thousand patients. Calls to the UCIL plant by police were twice assured that "everything is OK", and on the last attempt made, "we don't know what has happened, sir". In the plant, meanwhile, MIC began to engulf the control room and the adjoining offices.

December 3, 1984 3:00 am: The factory manager, arrived at the plant and sent a man to tell the police about the accident because the phones were out of order. The police were not told earlier because the company management had an informal policy of not involving the local authorities in gas leaks. Meanwhile, people were dying by the hundreds outside the factory. Some died in their sleep. Others ran into the cloud, breathing in more and more gas and dropping dead in their tracks.

Immediate Consequences

With the lack of timely information exchange between Union Carbide India Limited (UCIL) and Bhopal authorities, the city's Hamidia Hospital was first told that the gas leak was suspected to be ammonia, then phosgene. They were then told that it was methyl isocyanate (MIC), which hospital staff had never heard of, had no antidote for, and received no immediate information about. The gas cloud, composed mainly of materials denser than air, stayed close to the ground and spread in the southeasterly direction affecting the nearby communities. Most city residents who were exposed to the MIC gas were first made aware of the leak by exposure to the gas itself.

Subsequent Actions

Formal statements were issued that air, water, vegetation and foodstuffs were safe, but warned not to consume fish. The number of children exposed to the gases was at least 200,000. Within weeks, the State Government established a number of hospitals, clinics and mobile units in the gas-affected area to treat the victims.

Legal proceedings involving UCC, the United States and Indian governments, local Bhopal authorities, and the disaster victims started immediately after the catastrophe. The Indian Government passed the Bhopal Gas Leak Act in March 1985, allowing the Government of India to act as the legal representative for victims of the disaster, leading to the beginning of legal proceedings.

Initial lawsuits were generated in the United States federal court system in April 1985. Eventually, in an out-of-court settlement reached in February 1989, Union Carbide agreed to pay US$470 million for damages caused in the Bhopal disaster. The amount was immediately paid.

Post-settlement activity

UCC chairman and CEO Warren Anderson was arrested and released on bail by the Madhya Pradesh Police in Bhopal on 7 December 1984. Anderson was taken to UCC's house after which he was released six hours later on $2,100 bail and flown out on a government plane. Anderson, eight other executives and two company affiliates with homicide charges were required to appear in Indian court.

In response, Union Carbide said the company is not under Indian jurisdiction. In 1991, the local Bhopal authorities charged Anderson, who had retired in 1986, with manslaughter, a crime that carries a maximum penalty of 10 years in prison. He was declared a fugitive from justice by the Chief Judicial Magistrate of Bhopal on 1 February 1992 for failing to appear at the court hearings in a culpable homicide case in which he was named the chief defendant. Orders were passed to the Government of India to press for an extradition from the United States. From 2014, Dow is a named respondent in a number of ongoing cases arising from Union Carbide’s business in Bhopal.

A US Federal class action litigation, Sahu v. Union Carbide and Warren Anderson, had been filed in 1999 under the U.S. Alien Torts Claims Act (ATCA), which provides for civil remedies for "crimes against humanity." It sought damages for personal injury, medical monitoring and injunctive relief in the form of clean-up of the drinking water supplies for residential areas near the Bhopal plant. The lawsuit was dismissed in 2012 and subsequent appeal denied. Anderson died in 2014.

Long-term Health Effects

A total of 36 wards were marked by the authorities as being "gas affected," affecting a population of 520,000. Of these, 200,000 were below 15 years of age, and 3,000 were pregnant women. The official immediate death toll was 2,259, and in 1991, 3,928 deaths had been officially certified. The government of Madhya Pradesh confirmed a total of 3,787 deaths related to the gas release. Later, the affected area was expanded to include 700,000 citizens. A government affidavit in 2006 stated the leak caused 558,125 injuries including 38,478 temporary partial injuries and approximately 3,900 severely and permanently disabling injuries.

Ethical Negligence

The Corporate Negligence Argument: This point of view argues that management (and to some extent, local government) underinvested in safety, which allowed for a dangerous working environment to develop.

Safety audits: In September 1984, an internal UCC report on the West Virginia plant in the USA revealed a number of defects and malfunctions. It warned that "a runaway reaction could occur in the MIC unit storage tanks, and that the planned response would not be timely or effective enough to prevent catastrophic failure of the tanks". This report was never forwarded to the Bhopal plant, although the main design was the same.

The Disgruntled Employee Sabotage Argument: Now owned by Dow Chemical Company, Union Carbide maintains a website dedicated to the tragedy and claims that the incident was the result of sabotage, stating that sufficient safety systems were in place and operative to prevent the intrusion of water.

--------------------

As you read and analyze this case study, your reflective comments are requested on all of the following:

- Who are the stakeholders and how are they impacted both positively and negatively?

- What knowledge and skills are needed to implement sophisticated, appropriate, and workable solutions to the complex global problems facing the world today?

- What interdisciplinary perspectives would help identify innovative and non-obvious solutions?

- What insights can you articulate, based on your culture and other cultures with which you are familiar, to help understand your worldview and enable greater civic engagement?

- What is your position on the right thing(s) to do? After you submit your comment, please view and evaluate the feedback to your response that is automatically provided on the screen. Also, please take a moment to submit a comment on someone else's comment.

You need to be a member of The Ethical Engineer to add comments!

Join The Ethical Engineer

Feedback On Your Comment

Your topic coverage.

Topic coverage is based on the words used in each sentence; click below to see how each word contributed.

Some Observations

Give your feedback about the case study and automated feedback anonymously in this survey:

Hello, you need to enable JavaScript to use The Ethical Engineer.

Please check your browser settings or contact your system administrator.

- Open access

- Published: 10 May 2005

The Bhopal disaster and its aftermath: a review

- Edward Broughton 1

Environmental Health volume 4 , Article number: 6 ( 2005 ) Cite this article

441k Accesses

224 Citations

761 Altmetric

Metrics details

On December 3 1984, more than 40 tons of methyl isocyanate gas leaked from a pesticide plant in Bhopal, India, immediately killing at least 3,800 people and causing significant morbidity and premature death for many thousands more. The company involved in what became the worst industrial accident in history immediately tried to dissociate itself from legal responsibility. Eventually it reached a settlement with the Indian Government through mediation of that country's Supreme Court and accepted moral responsibility. It paid $470 million in compensation, a relatively small amount of based on significant underestimations of the long-term health consequences of exposure and the number of people exposed. The disaster indicated a need for enforceable international standards for environmental safety, preventative strategies to avoid similar accidents and industrial disaster preparedness.

Since the disaster, India has experienced rapid industrialization. While some positive changes in government policy and behavior of a few industries have taken place, major threats to the environment from rapid and poorly regulated industrial growth remain. Widespread environmental degradation with significant adverse human health consequences continues to occur throughout India.

Peer Review reports

December 2004 marked the twentieth anniversary of the massive toxic gas leak from Union Carbide Corporation's chemical plant in Bhopal in the state of Madhya Pradesh, India that killed more than 3,800 people. This review examines the health effects of exposure to the disaster, the legal response, the lessons learned and whether or not these are put into practice in India in terms of industrial development, environmental management and public health.

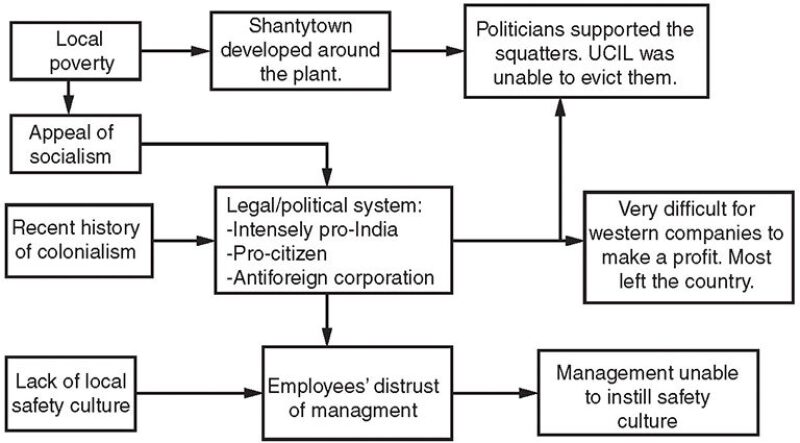

In the 1970s, the Indian government initiated policies to encourage foreign companies to invest in local industry. Union Carbide Corporation (UCC) was asked to build a plant for the manufacture of Sevin, a pesticide commonly used throughout Asia. As part of the deal, India's government insisted that a significant percentage of the investment come from local shareholders. The government itself had a 22% stake in the company's subsidiary, Union Carbide India Limited (UCIL) [ 1 ]. The company built the plant in Bhopal because of its central location and access to transport infrastructure. The specific site within the city was zoned for light industrial and commercial use, not for hazardous industry. The plant was initially approved only for formulation of pesticides from component chemicals, such as MIC imported from the parent company, in relatively small quantities. However, pressure from competition in the chemical industry led UCIL to implement "backward integration" – the manufacture of raw materials and intermediate products for formulation of the final product within one facility. This was inherently a more sophisticated and hazardous process [ 2 ].

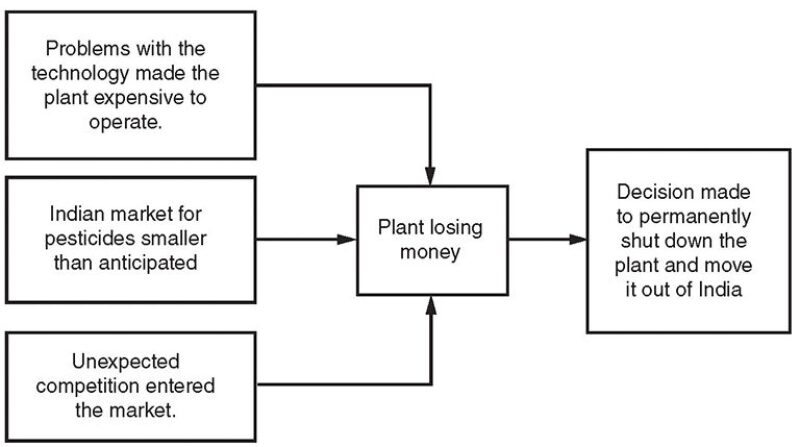

In 1984, the plant was manufacturing Sevin at one quarter of its production capacity due to decreased demand for pesticides. Widespread crop failures and famine on the subcontinent in the 1980s led to increased indebtedness and decreased capital for farmers to invest in pesticides. Local managers were directed to close the plant and prepare it for sale in July 1984 due to decreased profitability [ 3 ]. When no ready buyer was found, UCIL made plans to dismantle key production units of the facility for shipment to another developing country. In the meantime, the facility continued to operate with safety equipment and procedures far below the standards found in its sister plant in Institute, West Virginia. The local government was aware of safety problems but was reticent to place heavy industrial safety and pollution control burdens on the struggling industry because it feared the economic effects of the loss of such a large employer [ 3 ].

At 11.00 PM on December 2 1984, while most of the one million residents of Bhopal slept, an operator at the plant noticed a small leak of methyl isocyanate (MIC) gas and increasing pressure inside a storage tank. The vent-gas scrubber, a safety device designer to neutralize toxic discharge from the MIC system, had been turned off three weeks prior [ 3 ]. Apparently a faulty valve had allowed one ton of water for cleaning internal pipes to mix with forty tons of MIC [ 1 ]. A 30 ton refrigeration unit that normally served as a safety component to cool the MIC storage tank had been drained of its coolant for use in another part of the plant [ 3 ]. Pressure and heat from the vigorous exothermic reaction in the tank continued to build. The gas flare safety system was out of action and had been for three months. At around 1.00 AM, December 3, loud rumbling reverberated around the plant as a safety valve gave way sending a plume of MIC gas into the early morning air [ 4 ]. Within hours, the streets of Bhopal were littered with human corpses and the carcasses of buffaloes, cows, dogs and birds. An estimated 3,800 people died immediately, mostly in the poor slum colony adjacent to the UCC plant [ 1 , 5 ]. Local hospitals were soon overwhelmed with the injured, a crisis further compounded by a lack of knowledge of exactly what gas was involved and what its effects were [ 1 ]. It became one of the worst chemical disasters in history and the name Bhopal became synonymous with industrial catastrophe [ 5 ].

Estimates of the number of people killed in the first few days by the plume from the UCC plant run as high as 10,000, with 15,000 to 20,000 premature deaths reportedly occurring in the subsequent two decades [ 6 ]. The Indian government reported that more than half a million people were exposed to the gas [ 7 ]. Several epidemiological studies conducted soon after the accident showed significant morbidity and increased mortality in the exposed population. Table 1 . summarizes early and late effects on health. These data are likely to under-represent the true extent of adverse health effects because many exposed individuals left Bhopal immediately following the disaster never to return and were therefore lost to follow-up [ 8 ].

Immediately after the disaster, UCC began attempts to dissociate itself from responsibility for the gas leak. Its principal tactic was to shift culpability to UCIL, stating the plant was wholly built and operated by the Indian subsidiary. It also fabricated scenarios involving sabotage by previously unknown Sikh extremist groups and disgruntled employees but this theory was impugned by numerous independent sources [ 1 ].

The toxic plume had barely cleared when, on December 7, the first multi-billion dollar lawsuit was filed by an American attorney in a U.S. court. This was the beginning of years of legal machinations in which the ethical implications of the tragedy and its affect on Bhopal's people were largely ignored. In March 1985, the Indian government enacted the Bhopal Gas Leak Disaster Act as a way of ensuring that claims arising from the accident would be dealt with speedily and equitably. The Act made the government the sole representative of the victims in legal proceedings both within and outside India. Eventually all cases were taken out of the U.S. legal system under the ruling of the presiding American judge and placed entirely under Indian jurisdiction much to the detriment of the injured parties.

In a settlement mediated by the Indian Supreme Court, UCC accepted moral responsibility and agreed to pay $470 million to the Indian government to be distributed to claimants as a full and final settlement. The figure was partly based on the disputed claim that only 3000 people died and 102,000 suffered permanent disabilities [ 9 ]. Upon announcing this settlement, shares of UCC rose $2 per share or 7% in value [ 1 ]. Had compensation in Bhopal been paid at the same rate that asbestosis victims where being awarded in US courts by defendant including UCC – which mined asbestos from 1963 to 1985 – the liability would have been greater than the $10 billion the company was worth and insured for in 1984 [ 10 ]. By the end of October 2003, according to the Bhopal Gas Tragedy Relief and Rehabilitation Department, compensation had been awarded to 554,895 people for injuries received and 15,310 survivors of those killed. The average amount to families of the dead was $2,200 [ 9 ].

At every turn, UCC has attempted to manipulate, obfuscate and withhold scientific data to the detriment of victims. Even to this date, the company has not stated exactly what was in the toxic cloud that enveloped the city on that December night [ 8 ]. When MIC is exposed to 200° heat, it forms degraded MIC that contains the more deadly hydrogen cyanide (HCN). There was clear evidence that the storage tank temperature did reach this level in the disaster. The cherry-red color of blood and viscera of some victims were characteristic of acute cyanide poisoning [ 11 ]. Moreover, many responded well to administration of sodium thiosulfate, an effective therapy for cyanide poisoning but not MIC exposure [ 11 ]. UCC initially recommended use of sodium thiosulfate but withdrew the statement later prompting suggestions that it attempted to cover up evidence of HCN in the gas leak. The presence of HCN was vigorously denied by UCC and was a point of conjecture among researchers [ 8 , 11 – 13 ].

As further insult, UCC discontinued operation at its Bhopal plant following the disaster but failed to clean up the industrial site completely. The plant continues to leak several toxic chemicals and heavy metals that have found their way into local aquifers. Dangerously contaminated water has now been added to the legacy left by the company for the people of Bhopal [ 1 , 14 ].

Lessons learned

The events in Bhopal revealed that expanding industrialization in developing countries without concurrent evolution in safety regulations could have catastrophic consequences [ 4 ]. The disaster demonstrated that seemingly local problems of industrial hazards and toxic contamination are often tied to global market dynamics. UCC's Sevin production plant was built in Madhya Pradesh not to avoid environmental regulations in the U.S. but to exploit the large and growing Indian pesticide market. However the manner in which the project was executed suggests the existence of a double standard for multinational corporations operating in developing countries [ 1 ]. Enforceable uniform international operating regulations for hazardous industries would have provided a mechanism for significantly improved in safety in Bhopal. Even without enforcement, international standards could provide norms for measuring performance of individual companies engaged in hazardous activities such as the manufacture of pesticides and other toxic chemicals in India [ 15 ]. National governments and international agencies should focus on widely applicable techniques for corporate responsibility and accident prevention as much in the developing world context as in advanced industrial nations [ 16 ]. Specifically, prevention should include risk reduction in plant location and design and safety legislation [ 17 ].

Local governments clearly cannot allow industrial facilities to be situated within urban areas, regardless of the evolution of land use over time. Industry and government need to bring proper financial support to local communities so they can provide medical and other necessary services to reduce morbidity, mortality and material loss in the case of industrial accidents.

Public health infrastructure was very weak in Bhopal in 1984. Tap water was available for only a few hours a day and was of very poor quality. With no functioning sewage system, untreated human waste was dumped into two nearby lakes, one a source of drinking water. The city had four major hospitals but there was a shortage of physicians and hospital beds. There was also no mass casualty emergency response system in place in the city [ 3 ]. Existing public health infrastructure needs to be taken into account when hazardous industries choose sites for manufacturing plants. Future management of industrial development requires that appropriate resources be devoted to advance planning before any disaster occurs [ 18 ]. Communities that do not possess infrastructure and technical expertise to respond adequately to such industrial accidents should not be chosen as sites for hazardous industry.

Following the events of December 3 1984 environmental awareness and activism in India increased significantly. The Environment Protection Act was passed in 1986, creating the Ministry of Environment and Forests (MoEF) and strengthening India's commitment to the environment. Under the new act, the MoEF was given overall responsibility for administering and enforcing environmental laws and policies. It established the importance of integrating environmental strategies into all industrial development plans for the country. However, despite greater government commitment to protect public health, forests, and wildlife, policies geared to developing the country's economy have taken precedence in the last 20 years [ 19 ].

India has undergone tremendous economic growth in the two decades since the Bhopal disaster. Gross domestic product (GDP) per capita has increased from $1,000 in 1984 to $2,900 in 2004 and it continues to grow at a rate of over 8% per year [ 20 ]. Rapid industrial development has contributed greatly to economic growth but there has been significant cost in environmental degradation and increased public health risks. Since abatement efforts consume a large portion of India's GDP, MoEF faces an uphill battle as it tries to fulfill its mandate of reducing industrial pollution [ 19 ]. Heavy reliance on coal-fired power plants and poor enforcement of vehicle emission laws have result from economic concerns taking precedence over environmental protection [ 19 ].

With the industrial growth since 1984, there has been an increase in small scale industries (SSIs) that are clustered about major urban areas in India. There are generally less stringent rules for the treatment of waste produced by SSIs due to less waste generation within each individual industry. This has allowed SSIs to dispose of untreated wastewater into drainage systems that flow directly into rivers. New Delhi's Yamuna River is illustrative. Dangerously high levels of heavy metals such as lead, cobalt, cadmium, chrome, nickel and zinc have been detected in this river which is a major supply of potable water to India's capital thus posing a potential health risk to the people living there and areas downstream [ 21 ].

Land pollution due to uncontrolled disposal of industrial solid and hazardous waste is also a problem throughout India. With rapid industrialization, the generation of industrial solid and hazardous waste has increased appreciably and the environmental impact is significant [ 22 ].

India relaxed its controls on foreign investment in order to accede to WTO rules and thereby attract an increasing flow of capital. In the process, a number of environmental regulations are being rolled back as growing foreign investments continue to roll in. The Indian experience is comparable to that of a number of developing countries that are experiencing the environmental impacts of structural adjustment. Exploitation and export of natural resources has accelerated on the subcontinent. Prohibitions against locating industrial facilities in ecologically sensitive zones have been eliminated while conservation zones are being stripped of their status so that pesticide, cement and bauxite mines can be built [ 23 ]. Heavy reliance on coal-fired power plants and poor enforcement of vehicle emission laws are other consequences of economic concerns taking precedence over environmental protection [ 19 ].

In March 2001, residents of Kodaikanal in southern India caught the Anglo-Dutch company, Unilever, red-handed when they discovered a dumpsite with toxic mercury laced waste from a thermometer factory run by the company's Indian subsidiary, Hindustan Lever. The 7.4 ton stockpile of mercury-laden glass was found in torn stacks spilling onto the ground in a scrap metal yard located near a school. In the fall of 2001, steel from the ruins of the World Trade Center was exported to India apparently without first being tested for contamination from asbestos and heavy metals present in the twin tower debris. Other examples of poor environmental stewardship and economic considerations taking precedence over public health concerns abound [ 24 ].

The Bhopal disaster could have changed the nature of the chemical industry and caused a reexamination of the necessity to produce such potentially harmful products in the first place. However the lessons of acute and chronic effects of exposure to pesticides and their precursors in Bhopal has not changed agricultural practice patterns. An estimated 3 million people per year suffer the consequences of pesticide poisoning with most exposure occurring in the agricultural developing world. It is reported to be the cause of at least 22,000 deaths in India each year. In the state of Kerala, significant mortality and morbidity have been reported following exposure to Endosulfan, a toxic pesticide whose use continued for 15 years after the events of Bhopal [ 25 ].

Aggressive marketing of asbestos continues in developing countries as a result of restrictions being placed on its use in developed nations due to the well-established link between asbestos products and respiratory diseases. India has become a major consumer, using around 100,000 tons of asbestos per year, 80% of which is imported with Canada being the largest overseas supplier. Mining, production and use of asbestos in India is very loosely regulated despite the health hazards. Reports have shown morbidity and mortality from asbestos related disease will continue in India without enforcement of a ban or significantly tighter controls [ 26 , 27 ].

UCC has shrunk to one sixth of its size since the Bhopal disaster in an effort to restructure and divest itself. By doing so, the company avoided a hostile takeover, placed a significant portion of UCC's assets out of legal reach of the victims and gave its shareholder and top executives bountiful profits [ 1 ]. The company still operates under the ownership of Dow Chemicals and still states on its website that the Bhopal disaster was "cause by deliberate sabotage". [ 28 ].

Some positive changes were seen following the Bhopal disaster. The British chemical company, ICI, whose Indian subsidiary manufactured pesticides, increased attention to health, safety and environmental issues following the events of December 1984. The subsidiary now spends 30–40% of their capital expenditures on environmental-related projects. However, they still do not adhere to standards as strict as their parent company in the UK. [ 24 ].

The US chemical giant DuPont learned its lesson of Bhopal in a different way. The company attempted for a decade to export a nylon plant from Richmond, VA to Goa, India. In its early negotiations with the Indian government, DuPont had sought and won a remarkable clause in its investment agreement that absolved it from all liabilities in case of an accident. But the people of Goa were not willing to acquiesce while an important ecological site was cleared for a heavy polluting industry. After nearly a decade of protesting by Goa's residents, DuPont was forced to scuttle plans there. Chennai was the next proposed site for the plastics plant. The state government there made significantly greater demand on DuPont for concessions on public health and environmental protection. Eventually, these plans were also aborted due to what the company called "financial concerns". [ 29 ].

The tragedy of Bhopal continues to be a warning sign at once ignored and heeded. Bhopal and its aftermath were a warning that the path to industrialization, for developing countries in general and India in particular, is fraught with human, environmental and economic perils. Some moves by the Indian government, including the formation of the MoEF, have served to offer some protection of the public's health from the harmful practices of local and multinational heavy industry and grassroots organizations that have also played a part in opposing rampant development. The Indian economy is growing at a tremendous rate but at significant cost in environmental health and public safety as large and small companies throughout the subcontinent continue to pollute. Far more remains to be done for public health in the context of industrialization to show that the lessons of the countless thousands dead in Bhopal have truly been heeded.

Fortun K: Advocacy after Bhopal. 2001, Chicago , University of Chicago Press, 259.

Chapter Google Scholar

Shrivastava P: Managing Industrial Crisis. 1987, New Delhi , Vision Books, 196.

Google Scholar

Shrivastava P: Bhopal: Anatomy of a Crisis. 1987, Cambridge, MA , Ballinger Publishing, 184.

Accident Summary, Union Carbide India Ltd., Bhopal, India: December 3, 1984. Hazardous Installations Directorate. 2004, Health and Safety Executive

MacKenzie D: Fresh evidence on Bhopal disaster. New Scientist. 2002, 19 (1):

Sharma DC: Bhopal: 20 Years On. Lancet. 2005, 365 (9454): 111-112. 10.1016/S0140-6736(05)17722-8.

Article Google Scholar

Cassells J: Sovereign immunity: Law in an unequal world. Social and legal studies. 1996, 5 (3): 431-436.

Dhara VR, Dhara R: The Union Carbide disaster in Bhopal: a review of health effects. Arch Environ Health. 2002, 57 (5): 391-404.

Kumar S: Victims of gas leak in Bhopal seek redress on compensation. Bmj. 2004, 329 (7462): 366-10.1136/bmj.329.7462.366-b.

Castleman B PP: Appendix: the Bhopal disaster as a case study in double standards. The export of hazards: trans-national corporations and environmental control issues. Edited by: Ives J. 1985, London , Routledge and Kegan Paul, 213-222.

Mangla B: Long-term effects of methyl isocyanate. Lancet. 1989, 2 (8654): 103-10.1016/S0140-6736(89)90340-1.

Article CAS Google Scholar

Varma DR: Hydrogen cyanide and Bhopal. Lancet. 1989, 2 (8662): 567-568. 10.1016/S0140-6736(89)90695-8.

Anderson N: Long-term effects of mthyl isocyanate. Lancet. 1989, 2 (8662): 1259-10.1016/S0140-6736(89)92347-7.

Chander J: Water contamination: a legacy of the union carbide disaster in Bhopal, India. Int J Occup Environ Health. 2001, 7 (1): 72-73.

Tyagi YK, Rosencranz A: Some international law aspects of the Bhopal disaster. Soc Sci Med. 1988, 27 (10): 1105-1112. 10.1016/0277-9536(88)90305-X.

Carlsten C: The Bhopal disaster: prevention should have priority now. Int J Occup Environ Health. 2003, 9 (1): 93-94.

Bertazzi PA: Future prevention and handling of environmental accidents. Scand J Work Environ Health. 1999, 25 (6): 580-588.

Dhara VR: What ails the Bhopal disaster investigations? (And is there a cure?). Int J Occup Environ Health. 2002, 8 (4): 371-379.

EIA: India: environmental issues. Edited by: energy D. [ http://www.eia.doe.gov/emeu/cabs/indiaenv.html ]

CIA: The world factbook: India. [ http://www.cia.gov/cia/publications/factbook/geos/in.html#Econ ]

Rawat M, Moturi MC, Subramanian V: Inventory compilation and distribution of heavy metals in wastewater from small-scale industrial areas of Delhi, India. J Environ Monit. 2003, 5 (6): 906-912. 10.1039/b306628b.

Vijay R, Sihorwala TA: Identification and leaching characteristics of sludge generated from metal pickling and electroplating industries by Toxicity Characteristics Leaching Procedure (TCLP). Environ Monit Assess. 2003, 84 (3): 193-202. 10.1023/A:1023363423345.

Karliner J: The corporate planet. 1997, San Francisco , Sierra Club Books, 247.

Bruno KKJ: Earthsummit,biz:The corporate takeover of sustainable development. 2002, Oakland, Ca , First Food Books, 237.

Power M: The poison stream: letter from Kerala. Harper's. 2004, August, 2004: 51-61.

Joshi TK, Gupta RK: Asbestos in developing countries: magnitude of risk and its practical implications. Int J Occup Med Environ Health. 2004, 17 (1): 179-185.

Joshi TK, Gupta RK: Asbestos-related morbidity in India. Int J Occup Environ Health. 2003, 9 (3): 249-253.

Union Carbide: Bhopal Information Center. wwwbhopalcom/ucshtm. 2005

Corporate Watch UK: DuPont: A corporate profile. [ http://www.corporatewatch.org.uk/profiles/dupont/dupont4.htm ]

Beckett WS: Persistent respiratory effects in survivors of the Bhopal disaster. Thorax. 1998, 53 Suppl 2: S43-6.

Misra UK, Kalita J: A study of cognitive functions in methyl-iso-cyanate victims one year after bhopal accident. Neurotoxicology. 1997, 18 (2): 381-386.

CAS Google Scholar

Irani SF, Mahashur AA: A survey of Bhopal children affected by methyl isocyanate gas. J Postgrad Med. 1986, 32 (4): 195-198.

Download references

Acknowledgements

J. Barab, B. Castleman, R Dhara and U Misra reviewed the manuscript and provided useful suggestions.

Author information

Authors and affiliations.

Columbia University, Mailman School of Public Health, 600 W, 168th St., New York, NY, 10032, USA

Edward Broughton

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Edward Broughton .

Additional information

Competing interests.

The author(s) declare that they have no competing interests.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Authors’ original file for figure 1

Rights and permissions.

Reprints and permissions

About this article

Cite this article.

Broughton, E. The Bhopal disaster and its aftermath: a review. Environ Health 4 , 6 (2005). https://doi.org/10.1186/1476-069X-4-6

Download citation

Received : 21 December 2004

Accepted : 10 May 2005

Published : 10 May 2005

DOI : https://doi.org/10.1186/1476-069X-4-6

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Gross Domestic Product

- Indian Government

- Storage Tank

- Union Carbide Corporation

Environmental Health

ISSN: 1476-069X

- General enquiries: [email protected]

- Skip to main content

- Keyboard shortcuts for audio player

How the 1984 Bhopal gas tragedy in India has hurt multiple generations

Rhitu Chatterjee

Nearly 39 years after a gas from a pesticide factory poisoned tens of thousands of people in Bhopal, India, a new study finds that it also had health and economic impacts on men born a year later.

AILSA CHANG, HOST:

Nearly 39 years ago, the central Indian city of Bhopal was hit with what's still considered the world's worst industrial accident. Toxic gas leaked out of a pesticide factory run by the Indian subsidiary of an American company called Union Carbide. Thousands died immediately after that accident, and tens of thousands more have died since. Now a new study finds that the impacts of that horrific accident span generations. Researchers show that the disaster has burdened people who were born in the year after the accident with cancer, disabilities and poverty. NPR's Rhitu Chatterjee joins us now to explain these new findings. Hi, Rhitu.

RHITU CHATTERJEE, BYLINE: Hi, Ailsa.

CHANG: So can you just first tell us a little more about what happened back in 1984? And before you do, I just want to warn listeners that the details here are intense and devastating.

CHATTERJEE: Yeah. So this was on the night of December 3, 1984. The gas leak started shortly after midnight, when everyone was fast asleep. The gas was methyl isocyanate, an extremely toxic chemical used as an intermediary to make pesticides. And an estimated 40 tons of it leaked out and spread through Bhopal, exposing half a million residents. And, you know, people started waking up with their eyes and throats burning. And, you know, there was panic on the streets. And I spoke with this woman named Rehana Bi on the phone, who was only 16 at the time and lived very close to the factory - still does. And she told me that she remembers waking up that night to the sounds of neighbors banging on their door, calling her father's name.

REHANA BI: (Speaking Hindi).

CHATTERJEE: She says when they opened the door, they saw lots of people outside, all coughing and blinded by the gas. She says the air felt as if someone was burning tons of chilis. And so Rehana Bi and her family joined their neighbors on the street, trying to run away from the gas, but they couldn't escape it. Also, her mother was eight months pregnant, so they couldn't really run very fast. And a few hours after daybreak, she says, her 3-year-old brother died.

BI: (Speaking Hindi).

CHATTERJEE: And by that evening, her father had died, as had her pregnant mother. And this next thing, Ailsa, is really hard to hear. It kept me up at night after I talked to Rehana Bi. She told me that several of her family members saw the baby in her dead mother's womb moving until the following day, and then it died, too.

CHANG: Oh, my God, how devastating. Her family, though - they were just, you know, among thousands of people who lost loved ones - right? - immediately after.

CHATTERJEE: Exactly. And, you know, even the people who survived, people like Rehana Bi, have continued to struggle with a host of chronic health issues and are still struggling today.

CHANG: Right. Let's talk about that. I want to get into this new study. It shows that this tragedy, this disaster, had long-term effects on the following generations as well. Tell us more about what this study found.

CHATTERJEE: So the study used data from India's National Family Health Survey to try and get a sense of whether the generation that was in utero at the time of the accident - whether that generation was affected by the accident as well. And the study finds that indeed it was. In fact, that generation is doing worse than those who lived through the disaster, even. Here's study author Gordon McCord of the University of California San Diego.

GORDON MCCORD: All the way out to 100 kilometers from Bhopal, that 1985 birth cohort was very strange.

CHATTERJEE: Firstly, he says that there were fewer male babies born that year compared to previous years and later years. And he told me that that's not totally surprising because we know that male fetuses are more vulnerable to any kind of harmful exposure in utero.

CHANG: Oh, really? I had no idea. Well, what about the babies who were born that very year and who are now adults? How are they faring?

CHATTERJEE: So McCord says that the generation of men born in 1985 in Bhopal is worse off in terms of health, education and employment compared to those who were born before and after.

MCCORD: They have a higher likelihood of reporting to have cancer. They have a higher likelihood of reporting to have a disability that prevents them from being employed, and they on average have two years less of education.

CHATTERJEE: And that, you know, means that this generation was more likely to remain trapped in poverty because of the disaster, and the findings after this ongoing global discussion about what do we as a society owe future generations for damages caused by disasters.

CHANG: Yeah. Well, what do you think, Rhitu? Do you think these findings are likely to help the survivors of this accident or their children in any way?

CHATTERJEE: So it's too early to say anything about that. Now, those who lived through the disaster themselves have received very little compensation so far, and not a single person born after the disaster has received anything. But one advocate for Bhopal survivors that I spoke to recently told me that India hasn't yet shut the door on compensating the next generation. So she is hopeful that this study will, in time, help make a difference on that front.

CHANG: That is NPR's Rhitu Chatterjee. Thank you, Rhitu.

CHATTERJEE: Thank you, Ailsa.

(SOUNDBITE OF IMAN OMARI SONG, "MOVE TOO FAST (FEAT. ANNA WISE)")

Copyright © 2023 NPR. All rights reserved. Visit our website terms of use and permissions pages at www.npr.org for further information.

NPR transcripts are created on a rush deadline by an NPR contractor. This text may not be in its final form and may be updated or revised in the future. Accuracy and availability may vary. The authoritative record of NPR’s programming is the audio record.

- School Guide

- Class 8 Syllabus

- Maths Notes Class 8

- Science Notes Class 8

- History Notes Class 8

- Geography Notes Class 8

- Civics Notes Class 8

- NCERT Soln. Class 8 Maths

- RD Sharma Soln. Class 8

- Math Formulas Class 8

- CBSE Class 8 Civics Revision Notes

Chapter 2: Understanding Secularism

- Secularism in India

- Why is it Important to Separate Religion from State?

Chapter 3: Why do We Need a Parliament?

- Why Should People Decide?

- People and their Representatives

Chapter 4: Understanding Laws

- Do Laws Apply To All?

- Unpopular and Controversial Laws

Chapter 5: Judiciary

- Independent Judiciary of India

- Structure of Courts In India

- Different Branches of Legal System

- Access To the Courts

Chapter 6: Understanding Our Criminal Justice System

- Role of Police in Investigating a Crime

- Role of Public Prosecutor and Judge in Criminal Justice System

- What is Fair Trial?

Chapter 7: Understanding Marginalisation

- Development of Adivasis in India

Chapter 8: Confronting Marginalisation

- Invoking Fundamental Rights

- Laws For Marginalized - Overview and Examples

- Protecting the Rights of Dalits and Adivasis

- Scheduled Tribes (Prevention of Atrocities) Act, 1989

Chapter 9: Public Facilities

- Right to Clean Water as a Fundamental Right

- What is the Role of Government in Public Facilities?

- Do you think water in Chennai is available and affordable by all?

- In Search of Alternatives of Public Facilities

Chapter 10: Law and Social Justice

- What Is a Worker's Worth?

- Environmental Laws in India

Bhopal Gas Tragedy : Causes, effects and aftermath

The Bhopal gas tragedy occurred at midnight of December 2nd- 3rd December 1984 at the Union Carbide India Ltd (UCIL) pesticide facility in Bhopal, Madhya Pradesh. This catastrophe affected around 500,000 people along with many animals. People who were exposed are still suffering as a result of the gas leak’s long-term health impacts. Chronic eye difficulties and respiratory problems were some issues due to it. Children who have been exposed have stunted growth and cognitive impairments.

Table of Content

Bhopal Gas Tragedy

Bhopal gas tragedy case study, causes of bhopal gas tragedy, effects of bhopal gas tragedy, aftermath of bhopal gas tragedy.

Union Carbide was an American company that produced pesticides. MIC – methyl isocyanide, a dangerous poisonous gas began to leak at midnight on 2nd December 1984 from the Union Carbide factory. This MIC caused the Bhopal gas tragedy. The Bhopal gas tragedy was a fatal accident. It was one of the world’s worst industrial accidents.

UCIL was a pesticide manufacturing plant that produced the insecticide carbaryl. Carbaryl was discovered by the American company Union Carbide Corporation, which owned a significant share in UCIL. As an intermediary, UCIL produced carbaryl using methyl isocyanate (MIC). Other techniques for producing the ultimate product are available, but they are more expensive. The very toxic chemical MIC is extremely dangerous to human health. Residents of Bhopal in the area of the pesticide plant began to feel irritated by the MIC and began fleeing the city.

Bhopal UCIL constructed three underground MIC storage tanks which were named E610, E611, and E619. On October 1984, E610 was not able to maintain its nitrogen gas pressure and so the liquid which is present inside the tank would not pump out, because of which 42 tons of MIC in E610 was wasted. The chemical in E610 was left unpumped as they were not able to re-establish its pressure, which later became responsible for Bhopal Gas Tragedy.

The main causes of Bhopal Gas Tragedy are as follows:

- During the buildup to the spill, the plant’s safety mechanisms for the highly toxic MIC were not working. The alarm off tanks of the plant had not worked properly.

- Many valves and lines were in disrepair, and many vent gas scrubbers were not working, as was the steam boiler that was supposed to clean the pipes.

- The MIC was stored in three tanks, with tank E610 being the source of the leak. This tank should have held no more than 30 tonnes of MIC, according to safety regulations.

- Water is believed to have entered the tank through a side pipe as technicians were attempting to clear it late that fatal night.

- This resulted in an exothermic reaction in the tank, progressively raising the pressure until the gas was ejected through the atmosphere.

The main effects of the Bhopal Gas Tragedy are as follows:

- Thousands had died as a result of choking, pulmonary edema, and reflexogenic circulatory collapse.

- Neonatal death rates increased by 200 percent.

- A huge number of animal carcasses have been discovered in the area, indicating the impact on flora and animals. The trees died after a few days. Food supplies have grown scarce due to the fear of contamination.

- Fishing was also prohibited.

- In March 1985, the Indian government established the Bhopal Gas Leak Accident Act, giving it legal authority to represent all victims of the accident, whether they were in India or abroad.

- At least 200,000 youngsters were exposed to the gas.

- Hospitals were overcrowded, and there was no sufficient training for medical workers to deal with MIC exposure.

In the United States, UCC was sued in federal court. In one action, the court recommended that UCC pay between $5 million and $10 million to assist the victims. UCC agreed to pay a $5 million settlement. The Indian government, however, rejected this offer and claimed $3.3 billion. In 1989, UCC agreed to pay $470 million in damages and paid the cash immediately in an out-of-court settlement.

Warren Anderson, the CEO and Chairman of UCC was charged with manslaughter by Bhopal authorities in 1991. He refused to appear in court and the Bhopal court declared him a fugitive from justice in February 1992. Despite the central government’s efforts in the United States to extradite Anderson, nothing happened. Anderson died in 2014 without ever appearing in a court of law.

Bhopal Gas Tragedy continues to be an important warning sign for industrialization, for developing countries and in particular India, with human, environmental, and economic pitfalls. The economy of India is growing at a fast rate but at the cost of environmental health as well as public safety.

Frequently Asked Questions

What were the reasons behind bhopal gas tragedy.

The reasons behind Bhopal gas tragedy was a large volume of water had been introduced into the MIC tank and has caused a chemical reaction which did force the pressure release valve, which allowed the gas to leak.

What is the name of Bhopal gas case law?

The name is Union Carbide Corporation v.

Which gas was leaked in the Bhopal Gas Tragedy?

The gas which was leaked in the Bhopal Gas Tragedy is methyl isocyanate.

Was Bhopal gas tragedy an accident or experiment?

Bhopal gas tragedy was the world’s most worst industrial accident.

How many people died in the Bhopal Gas?

A total of 3,787 deaths were registered related to the gas release in case of Bhopal Gas Tragedy.

What were the four main demands of the Bhopal Gas victims?

The 4 demands of Bhopal Gas victims include: Proper medical treatment. Adequate compensation. Fixation of criminal responsibility Steps for prevention of such disasters in future.

How was Bhopal Gas Tragedy fixed?

Bhopal Gas Tragedy was fixed with construction of a secure landfill for holding the wastes from the two on-site solar evaporation ponds.

Please Login to comment...

Similar reads.

- Political Science-Class-8

- School Learning

- School Polity

Improve your Coding Skills with Practice

What kind of Experience do you want to share?

The long, dark shadow of Bhopal: still waiting for justice, four decades on

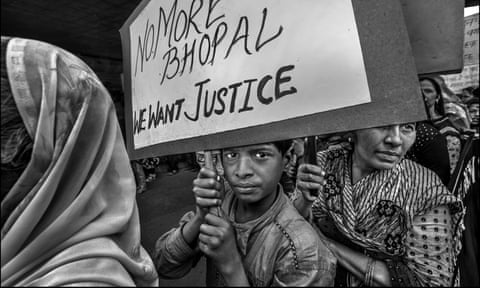

The cloud of poisonous gas that leaked from a rusting chemical plant in 1984 still blights the lives of tens of thousands of people in the Indian city, including many not born then. But Union Carbide never answered for the devastating contamination. Photographer Judah Passow spent a year recording the lives of some victims of the disaster

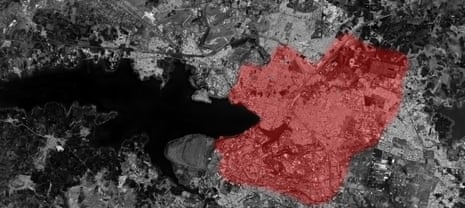

J ust after midnight on 2 December 1984 a storage tank at the Union Carbide chemical plant in Bhopal began leaking a gas called methyl isocyanate (MIC). The plant, in Madhya Pradesh, India, was equipped with six safety systems designed to detect such a leak, none of which were operational that night. Twenty-seven tons of MIC gas spread throughout the sleeping city .

As an engineer was flushing water through a corroded pipe in the MIC production complex, a series of valves failed, allowing the water to flow freely into one of the three-storey tanks holding the toxic chemical in a liquid state. This caused a rapid and violent reaction. The tank shattered in its concrete casing and spewed a deadly cloud of MIC, hydrogen cyanide, monomethylamine and other chemicals, all of which hugged the ground.

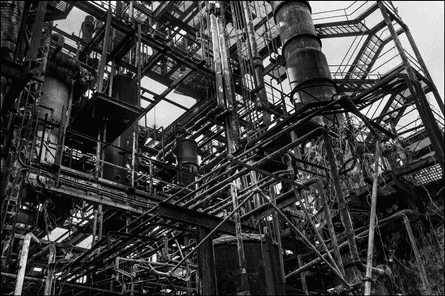

The derelict Union Carbide plant sits on a 20-hectare (49-acre) site in Bhopal’s old town

As the toxic cloud blanketed much of Bhopal, people began to die. Aziza Sultan, a survivor, remembers: “At about 12.30am, I woke to the sound of my baby coughing badly. In the half-light, I saw that the room was filled with a white cloud.

“I heard a lot of people shouting. They were shouting ‘Run! Run!’,’ she says. ‘Then I started coughing, with each breath seeming as if I was breathing in fire. My eyes were burning.”

Champa Devi Shukla recalls: “It felt like somebody had filled our bodies up with red chillies; our eyes had tears coming out, noses were watering, we had froth in our mouths. The coughing was so bad that people were writhing in pain.

“Some people just got up and ran in whatever they were wearing, or even if they were wearing nothing at all. People were only concerned as to how they would save their lives, so they just ran.”

In those apocalyptic moments, no one knew what was happening. People started dying in the most hideous ways. Some vomited uncontrollably, went into convulsions and dropped dead. Others choked, drowning in their own body fluids.

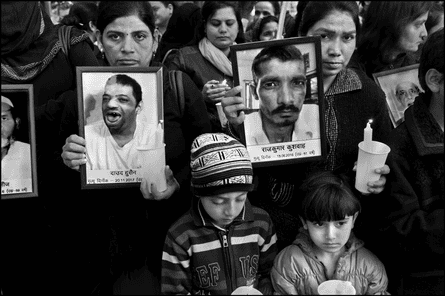

Staff from the Sambhavna clinic hold a vigil in memory of victims. It was built with funds raised in 1994 by the Bhopal Medical Appeal, which appeared in the Guardian and Observer on the disaster’s 10th anniversary. The clinic has treated more than 65,000 people and nearly half of the 55 staff are gas survivors

Many people died in the stampedes through narrow alleyways where street lamps, swamped in gas, burned brown. The crush of fleeing crowds wrenched children’s hands from their parents’ grasp. Families were literally ripped apart.

MIC, used in the production of pesticides, is highly corrosive if inhaled. Half a million people were exposed and at least 25,000 have died as a result. More than 150,000 people still suffer from disorders caused by the accident and the subsequent contamination – respiratory diseases, kidney and liver disorders, cancers and gynaecological issues.

No one knows exactly how many thousands of people died. Union Carbide put the number at 3,800. Municipal workers who collected bodies, loading them on to lorries to be buried in mass graves or burned on funeral pyres, say they handled at least 15,000 corpses. Based on numbers of burial shrouds sold in the city, survivors make the conservative claim that about 8,000 people died in the first week alone. But the dying has never stopped.

A satellite map of Bhopal, showing the extent of the toxic gas cloud, which affected half a million people

Rashida Bi, a survivor who has lost five members of her family to a variety of cancers over the past three decades, considers those who escaped with their lives “the unlucky ones”. She adds: “The lucky ones are those who died on that night.”

Union Carbide shut down the site and left it to rust. It has never been cleaned up and so the poisoning continues. In 1999, testing of groundwater and well-water near the site revealed mercury levels up to 6m times greater than what is accepted as safe by the US Environmental Protection Agency (EPA).

Images showing the plight of the survivors and their children. Many children of local people, whose drinking water was contaminated, were born with developmental issues. Among survivors, respiratory ailments are widespread

Chemicals were found in the water that cause cancer, brain damage and birth defects. Trichloroethene , a chemical shown to impair foetal development, was found at levels 50 times higher than EPA limits . Testing published in a 2002 report revealed poisons such as 1,3,5-trichlorobenzene, dichloromethane, chloroform, lead and mercury in women’s breastmilk.

In 2001, the Michigan-based Dow Chemical Company bought Union Carbide , acquiring its assets and liabilities. Dow, however, has steadfastly refused to clean up the Bhopal site. Nor has it provided safe drinking water, compensated the victims or shared with the Indian medical community any information it holds on the toxic effects of MIC.

The data that Bhopal’s doctors have requested, and say they need in order to deal with the lasting effects of the crisis, Dow has treated like a trade secret and held back.

Vimla Sahu, who lives near the abandoned Union Carbide plant, cannot conceal her anguish

Union Carbide built the Bhopal factory in the 1970s, confident that India represented a huge untapped market for its pesticides. However, sales never met the company’s expectations. Indian farmers, struggling to cope with droughts and floods, lacked the money to buy Union Carbide’s products.

For 15 years before the disaster, Union Carbide routinely dumped highly toxic chemical waste at sites inside and outside the factory.

Twin sisters Shazia and Fouziya in their home in the Nawab area of Bhopal, near the factory, where toxins leaked into the water supplies. They both have severe mental development issues, which doctors believe was due to genetic damage

Thousands of tons of pesticides, solvents, chemical catalysts and byproducts lay strewn across six hectares (16 acres) inside the plant. Evaporation ponds covering 14 hectares outside the factory were filled with thousands of litres of liquid waste.

The plant, which never reached its full production capacity, proved to be a loss-making venture and was shut down in the early 1980s, though large quantities of dangerous chemicals were left abandoned on the site.

Three huge steel tanks continued to hold more than 60 tons of MIC. Although MIC is a particularly unstable gas, Union Carbide’s elaborate safety systems were allowed to fall into disrepair and become ineffective. The factory managers’ reasoning seemed to be that, since production had stopped, no threat remained.

As monsoons battered the decaying plant, rain caused the chemical-waste evaporation ponds to overflow. Toxins penetrated the soil, leaching into underground channels. Contaminated water from wells was pumped into 42 neighbourhoods.

In secret tests carried out by Union Carbide in 1989 , the results of which were subsequently seen by the Bhopal Medical Appeal, the company concluded that the site was lethally contaminated. Groundwater instantly killed fish. Many of the places where the samples were taken were just inside the factory wall – people drew their water from wells and standpipes on the other side of the wall.

A gas-affected patient undergoes Panchakarma steam treatment, a traditional Ayurvedic therapy, at the Sambhavna clinic. The clinic describes its approach to treating survivors of the disaster as ‘offering drug-free therapies for chemically burdened bodies’

Despite having indisputable proof of the site’s toxicity, Union Carbide chose not to notify local people that the water was unsafe. It attacked those in the community who voiced concern, dismissing them as “troublemakers”.

The full extent of the contamination was not exposed until 1999, when Greenpeace investigators, after running a series of tests, reported that soil and water in and around the plant were contaminated by organochlorines and heavy metals, which are both highly toxic and accumulate in the body.

A follow-up study in 2002, which found mercury, lead and organochlorines in the breastmilk of women living near the plant, also discovered that the children of gas-affected women suffered an array of debilitating illnesses, including birth defects and reproductive disorders.

The “polluter pays” legal principle applies in India but Union Carbide and its parent company, Dow, have refused to pay compensation for this second environmental catastrophe of contaminated water.

A boy drinks water from a hand pump near the plant. Water samples taken in and around the factory were found to be highly contaminated by organochlorines and heavy metals

In 1989 Union Carbide, in a partial out-of-court settlement with the Indian government, agreed to pay $470m in compensation to the victims of the disaster. But the victims themselves were not consulted in the negotiations, and more than nine in 10 received a maximum of $500 each, or enough to pay medical expenses for five years.

Today, victims of the disaster eke out a perilous existence. More than 50,000 Bhopalis are unable to work because of their injuries. Many have no family left at all.

In 1991, India’s criminal justice system charged Warren Anderson, Union Carbide’s chairman and chief executive at the time of the disaster, with “culpable homicide not amounting to murder”. If he had been convicted in India, he would have faced a maximum of 10 years in prison. Anderson never stood trial. An Indian extradition request languished in the US courts for three and a half years without a response from officials.

In September 2014, a few months before the 30th anniversary of the disaster, Anderson, the son of a Brooklyn carpenter, died aged 92 in a nursing home in Vero Beach, Florida.

Doctors at the Chirayu cancer hospital in Bhopal examine a patient from one of the neighbourhoods around the abandoned plant

Union Carbide was charged with culpable homicide. The corporation, like its former chief executive, refused to face trial in India, and the charges have never been resolved.

Dow and Union Carbide merged in 2001. The agreement submitted to regulators omitted any mention of pending criminal cases against Union Carbide. Dow has been served summons to appear in court at least six times in Bhopal to explain Union Carbide’s continued absence. It has ignored all six notices.

Union Carbide remains liable for the environmental devastation it caused. Environmental damages were not addressed in the 1989 settlement, and the contamination continues to spread; these liabilities became the responsibility of Dow.

Some Dow shareholders tried to stop the merger, knowing that a corporation assumes the assets and the liabilities of a company it buys, according to established corporate law. Indeed, soon after it acquired Union Carbide, Dow settled a US lawsuit, paying out $2.2bn to compensate people in the US affected by Union Carbide’s use of asbestos in legacy products. But Dow maintains that it is not liable for Union Carbide’s actions in Bhopal.

Tim Edwards is executive trustee of the Bhopal Medical Appeal.

Demonstrators marching through the streets of Bhopal to mark the 34th anniversary of the Union Carbide gas disaster in 2018

- The Guardian picture essay

- Photography

- South and central Asia

Most viewed

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Environ Health

The Bhopal disaster and its aftermath: a review

Edward broughton.

1 Columbia University, Mailman School of Public Health, 600 W 168th St. New York, NY 10032 USA

This is an Open Access article distributed under the terms of the Creative Commons Attribution License ( http://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

On December 3 1984, more than 40 tons of methyl isocyanate gas leaked from a pesticide plant in Bhopal, India, immediately killing at least 3,800 people and causing significant morbidity and premature death for many thousands more. The company involved in what became the worst industrial accident in history immediately tried to dissociate itself from legal responsibility. Eventually it reached a settlement with the Indian Government through mediation of that country's Supreme Court and accepted moral responsibility. It paid $470 million in compensation, a relatively small amount of based on significant underestimations of the long-term health consequences of exposure and the number of people exposed. The disaster indicated a need for enforceable international standards for environmental safety, preventative strategies to avoid similar accidents and industrial disaster preparedness.

Since the disaster, India has experienced rapid industrialization. While some positive changes in government policy and behavior of a few industries have taken place, major threats to the environment from rapid and poorly regulated industrial growth remain. Widespread environmental degradation with significant adverse human health consequences continues to occur throughout India.

December 2004 marked the twentieth anniversary of the massive toxic gas leak from Union Carbide Corporation's chemical plant in Bhopal in the state of Madhya Pradesh, India that killed more than 3,800 people. This review examines the health effects of exposure to the disaster, the legal response, the lessons learned and whether or not these are put into practice in India in terms of industrial development, environmental management and public health.

In the 1970s, the Indian government initiated policies to encourage foreign companies to invest in local industry. Union Carbide Corporation (UCC) was asked to build a plant for the manufacture of Sevin, a pesticide commonly used throughout Asia. As part of the deal, India's government insisted that a significant percentage of the investment come from local shareholders. The government itself had a 22% stake in the company's subsidiary, Union Carbide India Limited (UCIL) [ 1 ]. The company built the plant in Bhopal because of its central location and access to transport infrastructure. The specific site within the city was zoned for light industrial and commercial use, not for hazardous industry. The plant was initially approved only for formulation of pesticides from component chemicals, such as MIC imported from the parent company, in relatively small quantities. However, pressure from competition in the chemical industry led UCIL to implement "backward integration" – the manufacture of raw materials and intermediate products for formulation of the final product within one facility. This was inherently a more sophisticated and hazardous process [ 2 ].

In 1984, the plant was manufacturing Sevin at one quarter of its production capacity due to decreased demand for pesticides. Widespread crop failures and famine on the subcontinent in the 1980s led to increased indebtedness and decreased capital for farmers to invest in pesticides. Local managers were directed to close the plant and prepare it for sale in July 1984 due to decreased profitability [ 3 ]. When no ready buyer was found, UCIL made plans to dismantle key production units of the facility for shipment to another developing country. In the meantime, the facility continued to operate with safety equipment and procedures far below the standards found in its sister plant in Institute, West Virginia. The local government was aware of safety problems but was reticent to place heavy industrial safety and pollution control burdens on the struggling industry because it feared the economic effects of the loss of such a large employer [ 3 ].

At 11.00 PM on December 2 1984, while most of the one million residents of Bhopal slept, an operator at the plant noticed a small leak of methyl isocyanate (MIC) gas and increasing pressure inside a storage tank. The vent-gas scrubber, a safety device designer to neutralize toxic discharge from the MIC system, had been turned off three weeks prior [ 3 ]. Apparently a faulty valve had allowed one ton of water for cleaning internal pipes to mix with forty tons of MIC [ 1 ]. A 30 ton refrigeration unit that normally served as a safety component to cool the MIC storage tank had been drained of its coolant for use in another part of the plant [ 3 ]. Pressure and heat from the vigorous exothermic reaction in the tank continued to build. The gas flare safety system was out of action and had been for three months. At around 1.00 AM, December 3, loud rumbling reverberated around the plant as a safety valve gave way sending a plume of MIC gas into the early morning air [ 4 ]. Within hours, the streets of Bhopal were littered with human corpses and the carcasses of buffaloes, cows, dogs and birds. An estimated 3,800 people died immediately, mostly in the poor slum colony adjacent to the UCC plant [ 1 , 5 ]. Local hospitals were soon overwhelmed with the injured, a crisis further compounded by a lack of knowledge of exactly what gas was involved and what its effects were [ 1 ]. It became one of the worst chemical disasters in history and the name Bhopal became synonymous with industrial catastrophe [ 5 ].

Estimates of the number of people killed in the first few days by the plume from the UCC plant run as high as 10,000, with 15,000 to 20,000 premature deaths reportedly occurring in the subsequent two decades [ 6 ]. The Indian government reported that more than half a million people were exposed to the gas [ 7 ]. Several epidemiological studies conducted soon after the accident showed significant morbidity and increased mortality in the exposed population. Table Table1. 1 . summarizes early and late effects on health. These data are likely to under-represent the true extent of adverse health effects because many exposed individuals left Bhopal immediately following the disaster never to return and were therefore lost to follow-up [ 8 ].

Health effects of the Bhopal methyl isocyanate gas leak exposure [8, 30-32].

Immediately after the disaster, UCC began attempts to dissociate itself from responsibility for the gas leak. Its principal tactic was to shift culpability to UCIL, stating the plant was wholly built and operated by the Indian subsidiary. It also fabricated scenarios involving sabotage by previously unknown Sikh extremist groups and disgruntled employees but this theory was impugned by numerous independent sources [ 1 ].

The toxic plume had barely cleared when, on December 7, the first multi-billion dollar lawsuit was filed by an American attorney in a U.S. court. This was the beginning of years of legal machinations in which the ethical implications of the tragedy and its affect on Bhopal's people were largely ignored. In March 1985, the Indian government enacted the Bhopal Gas Leak Disaster Act as a way of ensuring that claims arising from the accident would be dealt with speedily and equitably. The Act made the government the sole representative of the victims in legal proceedings both within and outside India. Eventually all cases were taken out of the U.S. legal system under the ruling of the presiding American judge and placed entirely under Indian jurisdiction much to the detriment of the injured parties.

In a settlement mediated by the Indian Supreme Court, UCC accepted moral responsibility and agreed to pay $470 million to the Indian government to be distributed to claimants as a full and final settlement. The figure was partly based on the disputed claim that only 3000 people died and 102,000 suffered permanent disabilities [ 9 ]. Upon announcing this settlement, shares of UCC rose $2 per share or 7% in value [ 1 ]. Had compensation in Bhopal been paid at the same rate that asbestosis victims where being awarded in US courts by defendant including UCC – which mined asbestos from 1963 to 1985 – the liability would have been greater than the $10 billion the company was worth and insured for in 1984 [ 10 ]. By the end of October 2003, according to the Bhopal Gas Tragedy Relief and Rehabilitation Department, compensation had been awarded to 554,895 people for injuries received and 15,310 survivors of those killed. The average amount to families of the dead was $2,200 [ 9 ].

At every turn, UCC has attempted to manipulate, obfuscate and withhold scientific data to the detriment of victims. Even to this date, the company has not stated exactly what was in the toxic cloud that enveloped the city on that December night [ 8 ]. When MIC is exposed to 200° heat, it forms degraded MIC that contains the more deadly hydrogen cyanide (HCN). There was clear evidence that the storage tank temperature did reach this level in the disaster. The cherry-red color of blood and viscera of some victims were characteristic of acute cyanide poisoning [ 11 ]. Moreover, many responded well to administration of sodium thiosulfate, an effective therapy for cyanide poisoning but not MIC exposure [ 11 ]. UCC initially recommended use of sodium thiosulfate but withdrew the statement later prompting suggestions that it attempted to cover up evidence of HCN in the gas leak. The presence of HCN was vigorously denied by UCC and was a point of conjecture among researchers [ 8 , 11 - 13 ].

As further insult, UCC discontinued operation at its Bhopal plant following the disaster but failed to clean up the industrial site completely. The plant continues to leak several toxic chemicals and heavy metals that have found their way into local aquifers. Dangerously contaminated water has now been added to the legacy left by the company for the people of Bhopal [ 1 , 14 ].

Lessons learned

The events in Bhopal revealed that expanding industrialization in developing countries without concurrent evolution in safety regulations could have catastrophic consequences [ 4 ]. The disaster demonstrated that seemingly local problems of industrial hazards and toxic contamination are often tied to global market dynamics. UCC's Sevin production plant was built in Madhya Pradesh not to avoid environmental regulations in the U.S. but to exploit the large and growing Indian pesticide market. However the manner in which the project was executed suggests the existence of a double standard for multinational corporations operating in developing countries [ 1 ]. Enforceable uniform international operating regulations for hazardous industries would have provided a mechanism for significantly improved in safety in Bhopal. Even without enforcement, international standards could provide norms for measuring performance of individual companies engaged in hazardous activities such as the manufacture of pesticides and other toxic chemicals in India [ 15 ]. National governments and international agencies should focus on widely applicable techniques for corporate responsibility and accident prevention as much in the developing world context as in advanced industrial nations [ 16 ]. Specifically, prevention should include risk reduction in plant location and design and safety legislation [ 17 ].

Local governments clearly cannot allow industrial facilities to be situated within urban areas, regardless of the evolution of land use over time. Industry and government need to bring proper financial support to local communities so they can provide medical and other necessary services to reduce morbidity, mortality and material loss in the case of industrial accidents.

Public health infrastructure was very weak in Bhopal in 1984. Tap water was available for only a few hours a day and was of very poor quality. With no functioning sewage system, untreated human waste was dumped into two nearby lakes, one a source of drinking water. The city had four major hospitals but there was a shortage of physicians and hospital beds. There was also no mass casualty emergency response system in place in the city [ 3 ]. Existing public health infrastructure needs to be taken into account when hazardous industries choose sites for manufacturing plants. Future management of industrial development requires that appropriate resources be devoted to advance planning before any disaster occurs [ 18 ]. Communities that do not possess infrastructure and technical expertise to respond adequately to such industrial accidents should not be chosen as sites for hazardous industry.