An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

- Advanced Search

- Journal List

- Springer Nature - PMC COVID-19 Collection

Evaluating a computerized maintenance management system in a low resource setting

Farah beniacoub.

1 Enabel, Belgian development agency, Rue Haute 147, 1000 Brussels, Belgium

Fabrice Ntwari

2 Central Directorate for Health Infrastructure and Equipment Management of the Ministry of Health (MoH), Avenue Pierre Ngendandumwe, Bujumbura, Burundi

Jean-Paul Niyonkuru

Marc nyssen.

3 Department of Public Health, Vrije Universiteit Brussel (VUB), Laarbeeklaan 103, 1090 Brussels, Belgium

Stefaan Van Bastelaere

This study documents the setup and roll-out of a Computerized Maintenance Management System (CMMS) in Burundi’s resource constrained health care system between 1/04/2017 and 31/03/2020. First, in 2017 a biomedical assets ontology was created, tailored to the local health system and progressively mapped on international GMDN (Global Medical Devices Nomenclature) and ICMD (International Classification and Nomenclature of Medical Devices) classifications. This ontology was the cornerstone of a web-based CMMS, deployed in the Kirundo and Muramvya provinces (6 health districts, 4 hospitals and 73 health centers).

During the study period, the total number of biomedical maintenance interventions increased from 4 to 350 per month, average corrective maintenance delays were reduced from 106 to 26 days and the proportion of functional medical assets grew from 88 to 91%.

This study proves that a sustainable implementation of a CMMS is feasible and highly useful in low resource settings, if (i) the implementation is done in a conducive technical environment with correct workshops and maintenance equipment, (ii) the active cooperation of the administrative authorities is ensured, (iii) sufficient training efforts are made, (iv) necessary hardware and internet connectivity is available and (v) adequate local technical support can be provided.

Introduction

Poor management of biomedical equipment and health care infrastructure is a problem of most health systems in low income countries. The most obvious reasons are:

Lack of accurate information: Very few Ministries of Health (MoH) have an accurate asset inventory at national, sub-national or health facility levels (diagnostic equipment, medical rolling stock, buildings, grounds or IT equipment [ 1 , 2 ]). It is even more difficult to obtain up-to-date information about the functional status, the maintenance history and the maintenance planning of equipment and buildings. This lack of essential information makes adequate planning, management and monitoring of major public investments in health care equipment and infrastructure very difficult[ 1 ]: numerous buildings are in dilapidated condition due to lack of maintenance, scrap yards are plenty of defective but in some cases perfectly repairable medical devices, biomedical equipment is distributed in an irrational way and sometimes cannot be put into operation due to simple lack of electricity or technical knowledge required for installation and configuration.

Absence of adapted, standardized nomenclature: The absence of national or international standardized nomenclatures for the identification of biomedical equipment and health system infrastructure has been observed in multiple low resource countries [ 2 , 3 ]. Often user-generated descriptions in free text are in use, resulting in typing errors and non-standard acronyms. The absence of an unambiguous ontology for biomedical engineering makes the exploitation of the available biomedical inventory time-consuming and error-prone. Nor does it allow health administrations to automatically evaluate the technical platform and infrastructure availability and maintenance status to national standards, insofar as these have been defined.

Shortage of qualified and skilled biomedical technicians: A marked shortage of skilled biomedical technicians in sub-Saharan Africa has been currently observed. This is particularly evident in rural areas and for the public sector. It contributes to the phenomenon of expensive maintenance contracts offered by international manufacturers, relying on expensive international technical personnel, which often proves impossible due to budgetary restrictions.

Lack of appropriate maintenance equipment, workshops and assistance: The scarce local technicians often do lack the appropriate equipment to carry out common repairs. They work in isolated settings without technical supervision or assistance. Therefore, necessary preventive maintenance tasks and curative repairs are not performed correctly or in due time, resulting in a very short functional lifetime of the biomedical equipment and consequently the frequent and long-term unavailability of sometimes essential diagnostic and/or therapeutic services for the patients [ 4 , 5 ].

In the past decade, digitalization was introduced in the health care systems of many developing countries. National e-health strategies were developed (e.g. Burundi’s Plan National de Développement de l'Informatique de Santé—PNDIS ) in which priority was given to internet connectivity, the setting up of national data warehouses including geo-referencing of aggregated health data, the computerization of hospitals and health centers or the automation of the pharmaceutical supply chain. Digitalization of biomedical equipment and health infrastructure management was unfortunately given a lower priority in these plans and it was seldom integrated in the national health management information systems. Moreover, countries are facing important challenges when implementing these e-health strategies, such as (i) unavailability of a central e-health authority which can coordinate the many over-priced donor-driven e-health projects, (ii) low-bandwidth or not widely available internet connectivity, (iii) lack of digital literacy (iv) lack of guidance on standards.

Research question

Our hypothesis is that implementation of a Computerized Maintenance Management System (CMMS) contributes to a more effective and efficient management of biomedical equipment and health infrastructure in a low resource setting.

Materials and methods

The study population of our action research included the Central Directorate for Health Infrastructure and Equipment Management of the MoH. At decentral level it included all public hospitals (n = 4) and health centers (n = 73) of the provinces of Muramvya and Kirundo.

The action research consisted of the following elements:

- Developing a standardized nomenclature for all biomedical equipment and health infrastructure.

- Establishing unambiguous quantitative standards for biomedical equipment and infrastructure based on the health norms of the MoH.

- Realizing a digital inventory of all biomedical material and health infrastructure based on the developed nomenclature.

- The development of a digital information system for the management of inventories, maintenance plans and maintenance activities and making the system available to the central services of the MoH and to the decentral level, i.e. the maintenance technicians in the 2 provinces concerned.

- The setup of biomedical workshops in the 2 concerned provinces with maintenance equipment and skilled technicians according to the national norms.

- The training of technical personnel of the central services of the MoH and of all available maintenance technicians in the 2 provinces.

The action research was analyzed in a quantitative and qualitative way covering (i) the use of the CMMS over a period of 3 years (2017–2020), (ii) the study of the feasibility, results and sustainability of the intervention and (iii) identification of any relevant failure- and success factors to be taken into account for future CMMS implementations in low resource settings.

In an initial phase, the ontology was developed for both biomedical equipment and medical infrastructure assets as described below:

Biomedical assets nomenclature

For biomedical equipment categories, local terminologies familiar to local maintenance technicians were used as a starting point. This resulting local nomenclature was progressively mapped to the international standards like GMDN (in 2018) [ 6 ] and ICMD-11 (in 2020) [ 7 ]. On a total of 131 local nomenclature codes, a corresponding GMDN code could be found for 97 (74%) items and a matching ICMD code for 83 (63%) items.

Information in the form of a 5-digit numeric GMDN Code is cross-referenced to a precisely defined Term Name and Definition, as seen in this example:

GMDN Term Name: Scalpel, single-use.

GMDN Code: 47,569

GMDN Definition: “A sterile, hand-held, manual surgical instrument constructed as a one-piece handle and scalpel blade (not an exchangeable component) used by the operator to manually cut or dissect tissue. The blade is typically made of high-grade stainless steel alloy or carbon steel and the handle is often made of plastic. This is a single-use device”.

Disadvantages of the GMDN classification were the fact that it was not available for free, that the code mapping took significantly longer to complete due to its much higher granularity compared to the ICMD classification and that GMDN matching also generated three times more ambiguous mappings, ultimately requiring an expert to make a choice between different possible candidate codes.

Infrastructure ontology

No useful international coding system could be found for classification of infrastructure assets. To this end, a new tri-axial nomenclature was locally developed, which took into account (i) the location of an item in the health pyramid (district hospital, health center …), (ii) the functional belonging of an item (radiology, laboratory, administration, ancillary building …) and (iii) its technical classification (roof truss, floor, network cabling …). The resulting infrastructure nomenclature contained 102 codes for the combinations of the first 2 axes each of which could be combined with 63 technical classification codes.

Health facility asset norms

Subsequently, existing Burundian quantitative national norms for infrastructure and biomedical equipment in district hospitals and health centers (numbers of operating theaters, reanimation sets, hospital beds, ECG machines etc.) were updated using the developed ontology for biomedical assets. The objective was to obtain an official reference against which the equipment status of each public health facility can be unambiguously assessed in order to enable better future investment planning and a more efficient organization of maintenance activities.

Baseline inventory

Before the start of the study, data on the biomedical assets of the public health facilities in Burundi had already been collected using an Akvo application on Android smartphones, with which technical characteristics, photos and descriptions of biomedical equipment and infrastructure were recorded according to WHO guidelines [ 1 ] in a semi-structured manner for each of the studied health facilities. This inventory was recuperated and migrated into the new system. Using the previously developed biomedical assets ontology, this baseline inventory could be initiated before even starting the actual development of the CMMS. This resulted in an initial list of 647 infrastructure items (only taking into account the first two coding axes) and 745 equipment items for both provinces.

CMMS functionalities

Before the start of the study, about 20 hospitals in Burundi already had a digital hospital information system with an integrated but seldom used CMMS module. In order to avoid unnecessary introduction of new information systems and to remain interoperable with the information systems already used by these hospitals, it was decided to further build on their public Java programming libraries for the development of the CMMS covering not only the hospitals but the whole district (including district offices and health centers).

The following functionalities, tailored to the specific needs of the Burundian health system, were developed:

- Management of equipment and infrastructure with the local ontologies and with international biomedical asset nomenclatures.

- Health facility management according to the hierarchical organizational structure of the Burundian health care system, with differentiated access rights to different categories of users per health facility (hospitals and health centers) and levels (national, provincial, district).

- Inventory of biomedical equipment and medical infrastructure, based on the previously developed ontology, including administrative, financial and technical characteristics of each asset and the storage of photos and any relevant asset documentation (manuals, loan agreements, inspection reports …).

- The planning of preventive maintenance and the management of the requests for corrective interventions in case of equipment breakdowns. For that purpose, standardized maintenance schemes have been developed for 68 (52%) equipment and 29 (28%) infrastructure codes.

- The registration of all maintenance activities including the identity of responsible maintenance technician, the outcome and the costs of the intervention.

- Automatic generation of reports and dashboards relating to the inventory status, maintenance progress and the extent to which the national quantitative standards for biomedical infrastructure and equipment are complied with.

CMMS implementation

The CMMS was developed as a central internet-accessible server application with a secure web interface. The application was developed in French as an open source Java project with a MySQL database backend and running on an Apache Tomcat server. The choice for this architecture was partly determined by the fact that (i) Burundi has a fairly broad coverage of 3G / 4G internet access, (ii) the registered data is automatically and permanently available in a central location, (iii) the hardware infrastructure costs are kept to a minimum and (iv) updates and maintenance only need to be performed in one single place. In order to also enable the registration of biomedical asset data (including photos) in remote health centers where internet connectivity is not available, an offline registration module was developed, enabling maintenance technicians to enter data on stand-alone devices in off-line mode for later synchronization with the central server.

Most maintenance technicians entered in unknown territory with the new CMMS application. Except for some basic knowledge of using Excel and Word, none of them had prior knowledge about a CMMS application. The average IT knowledge among the maintenance technicians was rather low. Therefore, a train-the-trainer approach was chosen, in which, in addition to the end users, expert users from the MoH received extensive training with regard to advanced functionalities and CMMS system management. End users have been successively trained multiple times on a steadily growing complexity of the software [ 8 ]. A team of 3 local private computer engineers in Bujumbura was additionally trained to be able to respond on demand (through a maintenance contract) in case of technical failures that can’t be resolved by the MoH’s own expert users.

Although the technical learning curve for using the application was quite short (1 week of training for the maintenance technicians), the need for additional training in biomedical maintenance procedures and strategies developed by the MoH became obvious very soon. For example, many maintenance technicians were relatively new to the sector, and others had developed their own working methods over time which were not always consistent with the procedures implemented in the CMMS. Therefore, the roll-out of the CMMS application got off to a relatively slow start. But the maintenance technicians have been monitored closely and over time they gradually discovered the benefits that could be derived from the application when performing their daily tasks. Repeated additional training was tailored to the needs they expressed and therefore fairly well attended which eventually resulted in a steadily increasing use of the CMMS.

System usage

Inventory: the initial baseline inventory with 1392 registered biomedical assets has been progressively expanded to 2906 permanently updated asset records after 3 years of operation. In the same period, 70 defective equipment items have been disposed of.

Total number of interventions: Fig. 1 shows that the monthly number of maintenance interventions on these assets has also seen exponential growth from 4 in the first half of 2017 (baseline), to 20 early 2018, 230 early 2019 and around 350 in March 2020; the arrows indicate the important role periodically repeated training efforts have played in this. On an average basis, preventive maintenance has been responsible for the bulk of the growth in maintenance activity by taking 89% of the total interventions.

Monthly number of maintenance interventions

Qualitative and quantitative analysis of the interventions

The analysis of the maintenance tasks demonstrated a favorable effect on the quality of the service that was provided by maintenance technicians in the 2 studied provinces. Firstly, the average response time to requests for corrective maintenance in case of biomedical equipment breakdowns, measured between the day of the application for assistance and the first intervention, decreased from 106 days in April 2017 to 26 days in March 2020 (Fig. 2 ). In the same period, the time that was needed to solve a maintenance problem dropped from 106 to 32 days.

Quality of corrective maintenance interventions

Secondly, whilst the corrective maintenance workload grew from 6 interventions in the first semester to 159 interventions in the sixth semester of the study, simultaneously the proportion of successfully solved cases improved from 92 to 98% (Fig. 2 ).

From April 2017 to march 2020, on a total of 635 interventions for corrective maintenance, 56% of the requests were issued by district hospitals, 38% by health centers and 6% by administrative structures. 61% of the interventions were related to infrastructure assets and 39% to equipment. During the last 18 months of the study, increasing numbers of preventive maintenance interventions were accompanied by a declining trend in (more expensive) corrective interventions, both in district hospitals and health centers, but this correlation was not statistically significant.

Functional capacity ratio F

In order to determine whether this growing number of maintenance interventions had an impact on the operational status of the biomedical heritage of the health facilities, the functional capacity ratio F was evaluated every six months, reflecting the proportion of active assets in functional condition:

F = functional capacity ratio in %

A tf = total number of functional assets registered in

the inventory.

A df = total number of functional assets in the inventory

that were decommissioned.

A t = total number of assets registered in the inventory

A d = total number of decommissioned assets

registered in the inventory.

The results, as shown in Fig. 3 , teach us that a rather modest but statistically significant improvement in F was observed growing from 88.69% in 2017 to 91.74% in 2020 (polynomial regression second order R = 0.9776). Interestingly, the obtained F-values correlate strongly with the absolute number of preventive maintenance interventions performed (linear regression R = 0.9524 and p < 0.005). (Table (Table1 1 )

Evolution of functional vs dysfunctional assets

CMMS implementation timeline

During our study period from April 2017 till March 2020 we successfully implemented a CMMS in a low resource setting.

While preparing the project, we realized that available international nomenclatures for biomedical equipment did not optimally match the concrete needs of developing countries. Although the ICMD classification showed larger gaps (e.g. for the identification of disability devices, medical furniture or energy supplies), fewer ambiguities were identified than with GMDN. The simplicity of the ICMD classification also better suited the available local coding competences. In order to achieve a better fit, further research will be needed to either generate a simplified sub-classification of GMDN or a more extensive version of ICMD. In any case, the free availability of such classification system seems to be an important factor for its usefulness in most of the sub-Saharan African countries.

Drawing up national standards for biomedical equipment and infrastructure that are adapted to the local health care system has proven to be a necessary and interesting exercise. Without such reference framework, solid biomedical heritage planning seems virtually impossible [ 2 , 5 ]. However, due to the very difficult political and budgetary situation of Burundi during the complete study period, it has not been possible to adequately evaluate the usefulness of the developed framework, because no substantial biomedical investment decisions have been made at the level of the Ministry.

On the technical side, the use of a web-based system with a central server has generated very few difficulties in Burundi, despite frequent interruptions in internet connectivity due to power outages around the country. Admittedly, there is rarely a compelling need to have biomedical inventory and maintenance data available in real time, and in the event of system failures, data can either be entered quite easily at a later stage or recorded on an off-line computer which will then be synchronized afterward. Yet, periodic synchronization of off-line computers remained problematic in a few remote areas where no reliable mobile network coverage was available.

Since the health care system in the provinces of Muramvya and Kirundo had been supported for quite some time by the Belgian Development Cooperation, the studied health facilities can generally be counted among the better equipped public health care structures of Burundi. This partly explains why the functional capacity ratio F left less room for improvement from the start. It may be expected that the F value would rise more strongly in less fortunate areas, given the fact that some authors state that between 40 and 70% of complex medical equipment is lying idle in sub-Saharan African countries [ 4 , 5 ]. The study data suggest that the improved functional capacity ratio F is caused by the intensified preventive maintenance activity. Further investigation also learned that the reason for that better F-score should in no case be sought in an increased number of decommissioned non-functional assets (which is theoretically possible and even desirable). On the contrary, decommissioning of assets continues to be a difficult administrative and cultural problem, even with an operational CMMS in place. The surrounding areas of many health facilities therefore remain littered with discarded defective equipment, which cannot be disposed of due to the lack of practical decommissioning procedures.

At the end of the study the MoH has been actively using the CMMS to determine its needs of infrastructure and medical equipment in consultation with its donors, in the context of the COVID-19 pandemic. In March 2020, after the first covid-19 cases in Burundi were identified, an overview of available CPAP ventilators, ICU beds and resuscitation equipment in the public health care facilities was immediately available and essential for the organization of the COVID-19 response.

The positive impact of action research in Kirundo and Muramvya led the Ministry of Health to include the roll-out of the software to the entire health system in its National Health Development Plan (2019–2023). However, the observed improvements come from a broader, successful combination of (1) completed maintenance teams with maintenance technician in 6 districts, (2) upgrade of technical platforms and workshops; (3) set-up of an operational frame with logistics for outreach activities to health centers; (4) use of a computerized maintenance management system (CMMS), (5) setup of a funding model.

Some of the donors have already committed to further expanding the CMMS to other parts of the country and a baseline inventory has already been entered into the system covering 17 of the 18 provinces for equipment and 11 provinces for infrastructure assets.

This study provides strong evidence for the hypothesis that a sustainable implementation of a CMMS is feasible and useful in low resource settings, if the implementation approach (i) is done in a conducive technical environment with correct workshops and maintenance equipment, (ii) ensures the active cooperation of the central and decentralized administrative authorities, (iii) sufficiently long and repetitive training efforts are made, (iv) necessary hardware and internet connectivity is available and (v) adequate local technical support can be provided.

A well-functioning CMMS may have relevant impact on the functionality of the health facilities, and by extension on the resilience of the health system. It indirectly contributes to a greater availability and equity of qualitative medical care and to universal health coverage in general.

Biographies

is a construction engineer working for the Belgian development Agency. She coordinates the implementation of the action-research on a decentralized maintenance strategy in Burundi together with VUB and the MoH.

is a biomedical engineer and former adviser at the MoH. He was an administrator at central level of the CMMS developed. He joined Enabel and continue to be a key role in the national roll-out of the software.

is a computer science engineer to the department of sanitary infrastructures and equipment at the MoH. As an administrator at central level of the CMMS, he has a key role in the implementation of the software.

is Professor Emeritus of Medical Informatics at the Free University Brussels. Secretary General of the Belgian National Committee on Biomedical Engineering within the Belgian Royal Academy of Sciences and Fine Arts.

is a general surgeon and public health expert at the Belgian Development Agency. As formulation manager he developed the Belgian project that assist the MoH in Burundi in the field of maintenance and asset management and has been coaching the project since the start in 2014.

Declarations

This article does not contain any studies with human or animal subjects performed by the any of the authors.

I, Farah Beniacoub, give my consent for manuscript (HEAL-D-20–00,414, Evaluating a Computerized Maintenance Management System in a low resource setting, Farah Beniacoub) to be published in Health and Technology Journal. I understand that the text and any pictures published in the article will be freely available on the Internet and may be seen by the general public. The pictures and text may also appear on other websites or in print, may be translated into other languages or used for commercial purposes. I have been offered the opportunity to read the manuscript.

Farah Beniacoub declares that she has no conflict of interest.

This article is part of the Computer Based Medical Systems

To read this content please select one of the options below:

Please note you do not have access to teaching notes, world‐class maintenance using a computerised maintenance management system.

Journal of Quality in Maintenance Engineering

ISSN : 1355-2511

Article publication date: 1 March 1998

This paper describes industrial research in which the implementation of a computerised maintenace management system (CMMS) was used as an effective tool that supports decision making with the objective of acheiving world‐class manufacturing status. Breakdown trends and performance levels were analysed in a continuous improvement environment. Critical performance measures were then identified and these became the driving force for specific benchmarking metrics and improvement techniques which enabled approaches to eliminate breakdown losses to be formulated. Data collected were analysed using a multiple criteria decision making (MCDM) methodology and the MCDM technique was implemented into the software in order to add value to the data. This gave increased support to decision making and enabled appropriate maintenance strategies to be implemented.

- Computer management

- Decision making

- Maintenance

- World‐class manufacturing

Labib, A.W. (1998), "World‐class maintenance using a computerised maintenance management system", Journal of Quality in Maintenance Engineering , Vol. 4 No. 1, pp. 66-75. https://doi.org/10.1108/13552519810207470

Copyright © 1998, MCB UP Limited

Related articles

We’re listening — tell us what you think, something didn’t work….

Report bugs here

All feedback is valuable

Please share your general feedback

Join us on our journey

Platform update page.

Visit emeraldpublishing.com/platformupdate to discover the latest news and updates

Questions & More Information

Answers to the most commonly asked questions here

Advertisement

Narrative literature review of facilitators and barriers to implementing computerized maintenance management systems in low-middle-income countries

- Review Paper

- Published: 13 March 2023

- Volume 13 , pages 373–378, ( 2023 )

Cite this article

- Danielle Cohen ORCID: orcid.org/0000-0002-9642-6422 1 ,

- Nikola Visnjic 1 ,

- Dominic Akaateba 2 &

- Kelly Hadfield 3

111 Accesses

Explore all metrics

Effective health technology management (HTM) is critical to healthcare delivery worldwide. The absence of proper HTM in low-resource settings leads to a lack of medical equipment that is operational or safe for use. Previous solutions including medical equipment donation have proven ineffective as The World Health Organization estimates that 50–80% of equipment is non-functional. This paper examines the facilitators and barriers to implementing Computerized Maintenance Management Systems (CMMS) as a means of improving HTM in Low-Middle-Income Countries (LMIC).

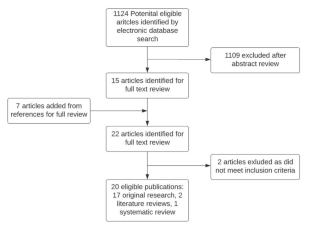

Five electronic databases were searched. Original research, literature reviews, and systematic reviews in English were included. Abstracts from all eligible articles were reviewed and, if indicated, the full text was screened. Furthermore, the reference list of included articles was scanned for relevant studies. Articles were analyzed using a ‘constant comparative’ method.

Themes identified include quality improvement, facilitators to CMMS implementation, and barriers to CMMS implementation. Hospitals in resource-limited settings report improvements in their maintenance practices and operational costs following the implementation of CMMS. A centralized internet-accessible server and standardization of training were found to be the main facilitators of CMMS implementation. Major barriers included difficulty retaining trained of trained engineers, the need for continued education, costs, the lack of consumables needed for equipment maintenance, and considerations of local context.

The importance of proper HTM in resource-limited hospital settings cannot be overlooked. The absence of proper HTM can be, in part, attributed to the shortage of skilled engineers. This emphasizes the need for access to continued biomedical engineering education to continue to advance and develop HTM in low resource settings. Although the implementation of CMMS in LMICs presents a multitude of challenges, our review found that it is by no means unfeasible, especially when adequate standardization and local context are taken into consideration.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Medenou D, Fagbemi LA, Houessouvo RC, et al. Medical devices in Sub-Saharan Africa: optimal assistance via a computerized maintenance management system (CMMS) in Benin. Health Technol. 2019;9:219–32. https://doi.org/10.1007/s12553-018-00283-3 .

Article Google Scholar

Ogembo-Kachieng’a M, Ogara WO. Strategic management of technology in public health sector in Kenya and South Africa. East Afr Med J. 2004;81(6):279–86. https://doi.org/10.4314/eamj.v81i6.9176 .

Zamzam AH, Abdul Wahab AK, Azizan MM, Satapathy SC, Lai KW, Hasikin K. A systematic review of Medical Equipment Reliability Assessment in improving the quality of Healthcare Services. Front Public Health. 2021;9:753951. https://doi.org/10.3389/fpubh.2021.753951 . Published 2021 Sep 27.

WHO. Introduction to medical equipment inventory management. Published 2011. https://www.who.int/publications/i/item/9789241501392 Accessed 22 Nov 2022.

Beniacoub F, Ntwari F, Niyonkuru JP, Nyssen M, Van Bastelaere S. Evaluating a computerized maintenance management system in a low resource setting. Health Technol (Berl). 2021;11(3):655–61. https://doi.org/10.1007/s12553-021-00524-y .

Wilson PT, Brooks JC, Otupiri E, Moresky RT, Morris MC. Aftermath of a clinical trial: evaluating the sustainability of a medical device intervention in Ghana. J Trop Pediatr. 2014;60(1):33–9. https://doi.org/10.1093/tropej/fmt074 .

Perry L, Malkin R. Effectiveness of medical equipment donations to improve health systems: how much medical equipment is broken in the developing world? Med Biol Eng Comput. 2011;49(7):719–22. https://doi.org/10.1007/s11517-011-0786-3 .

Mavalankar D, Raman P, Dwivedi H, Jain ML. Managing equipment for emergency obstetric care in rural hospitals. Int J Gynaecol Obstet. 2004;87(1):88–97. https://doi.org/10.1016/j.ijgo.2004.07.003 .

WHO. The sixtieth world health assembly: Having considered the report on health technologies. WHA60. 29. Published 2007 May 23. Accessed 22 Nov 2022.

Cohen T. Computerized maintenance management systems: how to match your department’s needs with commercially available products. J Clin Eng. 1995;20(6):457–68. https://doi.org/10.1097/00004669-199511000-00008 .

WHO. Computerized maintenance management system. Published 2011. https://www.who.int/publications-detail-redirect/9789241501415 Accessed 22 Nov 2022.

Barnett-Page E, Thomas J. Methods for the synthesis of qualitative research: a critical review. BMC Med Res Methodol. 2009;9:59. https://doi.org/10.1186/1471-2288-9-59 . Published 2009 Aug 11.

Thomas J, Harden A. Methods for the thematic synthesis of qualitative research in systematic reviews. BMC Med Res Methodol. 2008;8:45. https://doi.org/10.1186/1471-2288-8-45 . Published 2008 Jul 10.

Basiony M. Computerized Equipment Management System. J Clin Eng 2013;38(4).

Massambu C, Mwangi C. The Tanzania experience: clinical laboratory testing harmonization and equipment standardization at different levels of a tiered health laboratory system. Am J Clin Pathol. 2009;131(6):861–6. https://doi.org/10.1309/AJCP3ZAAFUPCIXIG .

Veluchamy S. A proposed computer-assisted preventive maintenance system. J Clin Eng. 1982;7(3):245–9. https://doi.org/10.1097/00004669-198207000-00014 .

Mutia D, Kihiu J, Maranga S. Maintenance management of Medical Equipment in Hospitals. Industrial Eng Lett. 2012;2(3):9–19.

Google Scholar

Cruz AM, Barr C, Denis ER. Offering integrated medical equipment management in an application service provider model. Biomed Instrum Technol . 2007;41(6):479–490. doi: https://doi.org/10.2345/0899-8205 (2007)41[479:OIMEMI]2.0.CO;2

Kutor JK, Agede P, Ali RH. Maintenance practice, causes of failure and Risk Assessment of Diagnostic Medical Equipment. J Biomed Eng Med Devic. 2017;2:123.

Marks IH, Thomas H, Bakhet M, et al. Medical equipment donation in low-resource settings: a review of the literature and guidelines for surgery and anaesthesia in low-income and middle-income countries. BMJ Global Health. 2019;4:e001785.

Ademe BW, Tebeje B, Molla A. Availability and utilization of medical devices in Jimma zone hospitals, Southwest Ethiopia: a case study. BMC Health Serv Res. 2016;16:287. https://doi.org/10.1186/s12913-016-1523-2 .

Malkin R, Keane A. Evidence-based approach to the maintenance of laboratory and medical equipment in resource-poor settings. Med Biol Eng Comput. 2010;48(7):721–6. https://doi.org/10.1007/s11517-010-0630-1 .

Thapa R, Yih A, Chauhan A, et al. Effect of deploying biomedical equipment technician on the functionality of medical equipment in the government hospitals of rural Nepal. Hum Resour Health. 2022;20:21. https://doi.org/10.1186/s12960-022-00719-y .

Penfold S, Shamba D, Hanson C, et al. Staff experiences of providing maternity services in rural southern Tanzania – a focus on equipment, drug and supply issues. BMC Health Serv Res. 2013;13:61. https://doi.org/10.1186/1472-6963-13-61 .

Download references

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and affiliations.

Faculty of Medicine, University of British Columbia, Vancouver, Canada

Danielle Cohen & Nikola Visnjic

Department of Medicine, Upper West Regional Hospital, Wa, Ghana

Dominic Akaateba

Department of Family Practice, University of British Columbia, Vancouver, Canada

Kelly Hadfield

You can also search for this author in PubMed Google Scholar

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Danielle Cohen and Nikola Visnjic. The first draft of the manuscript was written by Danielle Cohen and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Correspondence to Danielle Cohen .

Ethics declarations

Competing interests.

The authors have no relevant financial or non-financial interests to disclose.

Ethics approval

This literature review did not require ethics approval.

Consent to participate

This review does not require consent to participate as it only reviews previously published literature.

Consent to publish

This review does not require consent to publish as it only reviews previously published literature.

Additional information

Publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Cohen, D., Visnjic, N., Akaateba, D. et al. Narrative literature review of facilitators and barriers to implementing computerized maintenance management systems in low-middle-income countries. Health Technol. 13 , 373–378 (2023). https://doi.org/10.1007/s12553-023-00743-5

Download citation

Received : 25 January 2023

Accepted : 16 February 2023

Published : 13 March 2023

Issue Date : June 2023

DOI : https://doi.org/10.1007/s12553-023-00743-5

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Health Technology Management

- Low-middle-income countries

- Low-resource setting

- Computerized maintenance Management Systems

- Clinical Engineering

- Equipment Bottleneck

- Find a journal

- Publish with us

- Track your research

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

IMPLEMENTATION OF COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEM (CMMS) FOR MEDIUM TRANSPORT AIRCRAFT UNDERGRADUATE THESIS REZA RAMADHANA INDARYANTO 0806472276 FACULTY OF ENGINEERING INTERNATIONAL PROGRAM DEPOK JUNE 2013

Related Papers

System Safety: Human - Technical Facility - Environment

Piotr Kuryło

In the present paper, the scope of the process line maintenance in the production plant has been presented. The issues associated with the basic functions and characteristics of the services dealing with this problem, which is crucial for the production plant, have been discussed. Modern CMMS (Computerized Maintenance Management Systems) have been discussed, while indicating their specific advantages, among others, the possibility of keeping records of machinery and equipment, maintenance schedules and various types of alarms, which may disrupt or suspend the operation of production facilities, so that these systems ensure the safety of fault-free operation of machinery and equipment.

Ali A. Majeed

Giorgio Rendra

Elamin Mohammed

Sudan Currency Printing Press is a large and strategic company; it works in the field of security and commercial printing. The maintenance is managed and operated traditionally and depends mainly on reporting system. As a result there are delays and difficulties in tracing work orders and decision making. Also the system offers little chance for improvement. To solve this problem a locally designed computerized maintenance management system (CMMS) is applied together with modern maintenance techniques. As a result key performance indicators (KPI) are enhanced and reductions in maintenance costs are achieved.

Procedia Engineering

Ken Henderson

Awisi Godfred

: The Naval Aviation Logistics Command Management Information System (NALCOMIS) is the next generation solution to the information assimilation gap faced by Naval Aviation maintenance managers. This thesis examines the scope of the problem at the Organizational and Intermediate levels of maintenance, and the intended effect of NALCOMIS and three peripheral information systems. The underlying concepts of the four systems investigated are used to explore Artificial Intelligence as the logical augmentation or follow-on to the NALCOMIS program. Recommendations regarding the implementation of AI and expert systems are made. Additional keywords: Scenarios; MRMS (Mechanized repairables management system); VAMP (Versatile automated management program); VAST (Versatile avionics shop test); SIDMS (Status, inventory, data management system). (Author).

Conference proceedings : ... Annual International Conference of the IEEE Engineering in Medicine and Biology Society. IEEE Engineering in Medicine and Biology Society. Annual Conference

John Enderle

The purpose of this project was to design and implement a computerized maintenance management system (CMMS) to be used at the Chilean Naval Hospital Biomedical Engineering Department. It is designed to meet the specific needs of this military facility and follows the generic clinical engineering maintenance management system suggested by Association for the Advancement of Medical Instrumentation (AAMI).

Muhammad Hassan Ali

Maintenance, a fundamental of reliable operations, has gone through an evolution from reactive to proactive strategies. In this evolution, the technology layer has been added in terms of computerized maintenance management system (CMMS). This paper aims to explore the current status of CMMS in the process industries of a developing country. For this study, data were collected via questionnaire from 62 publicly listed companies along with an analysis of their annual reports. Moreover, six interviews of CMMS consultants were conducted. It was found that 56% of the sampled companies had a CMMS running, while 44% had no such solution. The key performance indicator (KPI) of ‘% replacement asset value’ (%RAV) was further determined, which was found to be 3.74% for companies with CMMS and 5.67% for companies with no CMMS; considering the global benchmark of 2.5%. The challenges to CMMS implementation included unawareness about function of CMMS, erroneous data and weak change management. Ev...

Applied Sciences

Đorđe Dobrota

Computerized maintenance management systems (CMMSs) are software packages that support or organize the maintenance tasks of assets or equipment. They are found in the background of any ship maintenance operation and are an important part of maintenance planning, spare parts supply, record keeping, etc. In the marine market, there are a number of CMMSs that are competing fiercely to program a better and more modern program that will capture the market, which has been accompanied by published analyses and scientific papers. At the same time, the quality of the data entered into CMMS databases is questionable, a fact that has been ignored in practice and scientific circles; until recently, there were no published analyses and there was no way to measure the quality of the data entered. This article presents two proposals for improving the quality of CMMS databases and calculates their potential benefits. By implementing the first proposal, the evaluation methodology for the ship’s Plan...

Edoghogho Ogbeifun

Those involved in maintenance operations are enjoying the benefits of information and communication technology in the planning and management of maintenance activities, resource management and planned production. In the digital space, the computer-based operating systems, commonly referred to as computerised maintenance management systems (CMMSs), enable quick and effective communication between stakeholders, facilitate improved planning, easy access to historical data, reporting and performance improvements of the maintenance function. However, success in the use of CMMSs depends on the human capacity of the users of the system. In practice, many organisations use the CMMS tool for planning, operations management and reporting, without the aid of detailed analysis of operational information in the CMMS database. They fail to harness all the possible benefits. Three case studies were used to illustrate the situation. Two of them refer to academic institutions and the third is a manu...

RELATED PAPERS

Dillafarra Hakim

Iolanda Pensa

Protoplasma

Neuro-Oncology

regina del campo

Cadernos de saude publica

Javier Amadeo

kamel H A R rahouma

Information Systems Security

Nora Cuppens

Journal of Fluorine Chemistry

andrea pace

Angelica Villamizar

Rodrigo Velasco

International Journal of Refrigeration

Ramón Cabello López

Journal of Agricultural and Food Chemistry

José C. del Río

The Phenomenoogy of Religious Belief

Michael Shapiro

carolina lorenzo

International Journal of Academic Research in Business and Social Sciences

Noor Rahmat

Angga Purnama

The European Physical Journal C

Iris Alvarez Mendoza

IEEE Transactions on Image Processing

Nhat Nguyen

Molecular Biology and Evolution

Journal of Racial and Ethnic Health Disparities

Giulia Earle-Richardson

Louise Ramos

Annals of Diagnostic Pathology

Makina Tasarım ve İmalat Dergisi

Mustafa Yurdakul

1819-2019: 200 anni di liceo Brocchi

Francesco Tessarolo

Einstein (São Paulo)

Milton Alves

See More Documents Like This

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

IMAGES

VIDEO

COMMENTS

This review article is to briefly describe what the Smart Maintenance Management System will look like in future industrial and commercial use machines in day-to-day life, as well as the importance of computerized maintenance in small and medium enterprises and shows the suitable publication for submitting the maintenance related research articles.

2.1 Computerized Maintenance Management Systems (CMMS). A CMMS is an asset that supports maintenance strategy based on an information system and a set of functions aimed to produce indicators by processing information to support maintenance activities [].In this context; CMMS enables maintenance management to control a wide variety of data on maintenance workforce, spare parts inventories ...

Abstract. Computerised maintenance management systems (CMMSs) are vital for the coordination of all activities related to the availability, productivity and maintainability of complex systems ...

Abstract and Figures. Computerized Maintenance Management System (CMMS) is a maintenance planning and management tool that has been widely accepted and utilized in manufacturing, industrial ...

The functionality of maintenance is much enhanced and automated by the implementation of a Computerized Maintenance Management System (CMMS) in an organization. CMMS is a maintenance-based software also known as Enterprise Asset Management (EAM) that is utilized to plan, schedule, manage, and monitoring maintenance activities related to equipment, machinery, automobiles, or other facilities ...

The management of maintenance in a large industrial operation is complex and has a significant impact on the profitability of the business. Managing this process effectively without computer-based support is almost impossible, but achieving successful implementation of these systems requires a major change-management program over many years.

Recently, most companies and organizations implement computerized maintenance-management systems (CMMS), such that the historical failure data of the components can be collected, stored, and used ...

Abstract. This study documents the setup and roll-out of a Computerized Maintenance Management System (CMMS) in Burundi's resource constrained health care system between 1/04/2017 and 31/03/2020. First, in 2017 a biomedical assets ontology was created, tailored to the local health system and progressively mapped on international GMDN (Global ...

Maintenance, a fundamental of reliable operations, has gone through an evolution from reactive to proactive strategies. In this evolution, the technology layer has been added in terms of computerized maintenance management system (CMMS). This paper aims to explore the current status of CMMS in the process industries of a developing country.

research-article . Free Access. Share on. Maintenance decision making, supported by computerized maintenance management system. Authors: Ali Rastegari.

Abstract. This paper describes industrial research in which the implementation of a computerised maintenace management system (CMMS) was used as an effective tool that supports decision making with the objective of acheiving world‐class manufacturing status. Breakdown trends and performance levels were analysed in a continuous improvement ...

2001. From this review of the 6 aspects of opportunity for inconsistency to corrupt or skew the reliability of data, it becomes apparent why members of management must provide the standards of operation…. Expand. 6. 2 Excerpts. Semantic Scholar extracted view of "Computerized maintenance management systems" by Theodore Cohen et al.

In various studies in the maintenance literature, such as [1], [3] and [4], the This paper is written based on the need for term "type" has been used similarly to other terms, such Computerized Maintenance Management System's as "approach", "action", "strategy" and "policy".

This study documents the setup and roll-out of a Computerized Maintenance Management System (CMMS) in Burundi's resource constrained health care system between 1/04/2017 and 31/03/2020. First, in 2017 a biomedical assets ontology was created, tailored to the local health system and progressively mapped on international GMDN (Global Medical ...

A Computerized maintenance management system (CMMS) is basically information systems adapted to serve maintenance [ 10 ]. CMMS aids in the process of data collection, recording, storing, updating, processing, communicating, and forecasting. It is essential for planning, scheduling, and controlling the maintenance activities.

System cost is influenced by (i) the level of workforce knowledge, (ii) the quality of the computerised maintenance management system and (iii) the quality of the monitoring equipment. A factorial experiment design is then conducted to make inference about the effects of influencing factors and the effect of their interactions on system cost.

Using Computerized Maintenance Management System (CMMS) in Healthcare Equipments Maintenance Operations ... a magazine style journal that publishes full-length research papers in all disciplines ...

the process of maintenance and engineering and the amount of information handled in a typical maintenance system require computer support. Appropriate computer support provides the means for quick and timely response. A Computerized maintenance management system (CMMS) is basically infor-mation systems adapted to serve maintenance [10].

#1065 IMPLEMENTATION OF A COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEM FOR THE CITY OF ATLANTA Samuel O. Atere-Roberts, P.E Scott A. Bash Brown and Caldwell/Williams Russell and Johnson Joint Venture 41 Perimeter Center East, Suite 400 Atlanta, GA 30346 ABSTRACT This paper describes the activities performed to implement a Computerized Maintenance Management System (CMMS) at three water ...

This paper examines the facilitators and barriers to implementing Computerized Maintenance Management Systems (CMMS) as a means of improving HTM in Low-Middle-Income Countries (LMIC). Methods. Five electronic databases were searched. Original research, literature reviews, and systematic reviews in English were included.

Purpose The purpose of this paper is to review the literature on maintenance management and suggest possible gaps from the point of view of researchers and practitioners. Design/methodology ...

Academia.edu is a platform for academics to share research papers. ... Wireman (1994) argued that in a computerized maintenance management system, there are needs of proper examination about the importance of having an understanding of the functions that come with major maintenance: inspection and maintenance service, equipment Installation ...

Abstract and Figures. Increasing human dependence on engineering systems has recently made maintenance a higher priority. Thus, it becomes essential to study the many developments in this field ...