Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- My Account Login

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 22 September 2020

Impacts of solar intermittency on future photovoltaic reliability

- Jun Yin ORCID: orcid.org/0000-0003-2706-0620 1 ,

- Annalisa Molini ORCID: orcid.org/0000-0003-3815-3929 2 , 3 &

- Amilcare Porporato ORCID: orcid.org/0000-0001-9378-207X 4 , 5

Nature Communications volume 11 , Article number: 4781 ( 2020 ) Cite this article

11k Accesses

46 Citations

145 Altmetric

Metrics details

- Climate-change impacts

- Energy modelling

As photovoltaic power is expanding rapidly worldwide, it is imperative to assess its promise under future climate scenarios. While a great deal of research has been devoted to trends in mean solar radiation, less attention has been paid to its intermittent character, a key challenge when compounded with uncertainties related to climate variability. Using both satellite data and climate model outputs, we characterize solar radiation intermittency to assess future photovoltaic reliability. We find that the relation between the future power supply and long-term mean solar radiation trends is spatially heterogeneous, showing power reliability is more sensitive to the fluctuations of mean solar radiation in hot arid regions. Our results highlight how reliability analysis must account simultaneously for the mean and intermittency of solar inputs when assessing the impacts of climate change on photovoltaics.

Similar content being viewed by others

Climate change extremes and photovoltaic power output

Sarah Feron, Raúl R. Cordero, … Robert B. Jackson

Solar power generation intermittency and aggregation

Cong Wu, Xiao-Ping Zhang & Michael Sterling

A climatology of weather-driven anomalies in European photovoltaic and wind power production

Linh Ho-Tran & Stephanie Fiedler

Introduction

Increasing the use of solar energy is widely regarded as one of the most effective approaches to reduce CO 2 emissions, yet the short-term intermittent nature imposes definite limitations to its reliability. While this problem may be partially solved by power storage, geographic dispersion, load control, and radiation forecasting 1 , 2 , 3 , it still has significant impacts on the grid integration of solar energy. For instance, photovoltaic power plants in Northwestern China (capacity of 43.87 GW in 2019, 1/3 of China’s total) were punished for providing intermittent energy to the Northwest Grid with fines of $28 million US dollars in 2017, $42 million in 2018, and $28 million for the first half of the year 2019, whereas coal-fired and hydropower plants were rewarded for their constant and even dispatchable sources of electricity 4 , 5 , 6 . Similarly, the example of Kauai island, Hawaii, a world pioneer in using renewable energy 7 , currently relies on diesel generators on overcast days 8 , 9 . While the solar radiation varies across a range of timescales, here we focus on the daily level, which accounts for a significant portion of the penalty in the case of the Northwestern China 4 , 5 and is closely related to the power reliability in Kauai, Hawaii 9 .

The daily radiation is expected to change in future climates due to altered cloud and aerosol patterns 10 , 11 , 12 , 13 , 14 , presenting additional challenges for the long-term planning and management of solar energy. Previous studies have focused mostly on the relative change of long-term mean radiation input 15 , 16 , 17 , 18 , 19 . While mean metrics are essential, the portion of time with energy supply lower than the demand, termed loss-of-load probability (LOLP) 20 , which is related to the reliability and the market values of power output, cannot be captured by mean values alone. Power reliability is vital for grid planning and management. For example, the solar plant from Tesla is expected to provide 52 MWh of electricity every evening to the power grid in Kauai, Hawaii 7 . Tesla’s design of 13 MW solar array and 52 MWh effective battery storage result in an LOLP of 0.12, possibly maximizing the net profit while still satisfying the reliability requirement 9 . In a grid-connected system, LOLP is directly associated with the operating cost of the peaking plants (e.g., diesel generators in Kauai, Hawaii 8 , 9 , hydropower stations in Northwest of China 21 , gas turbines in the Great Plains, United States 22 ) and thus linked to the market values of the solar energy.

To investigate the impacts of future climates on LOLP, we combine here satellite-derived data and climate model outputs. In particular, we focus on the impact of incident solar irradiance, one of the dominant factors controlling solar power generation 15 , 17 , 18 . We show the nonlinear behaviors of LOLP in response to climate change, pointing towards a tradeoff between the potential power outputs and the power reliability.

Characterizing solar energy intermittency

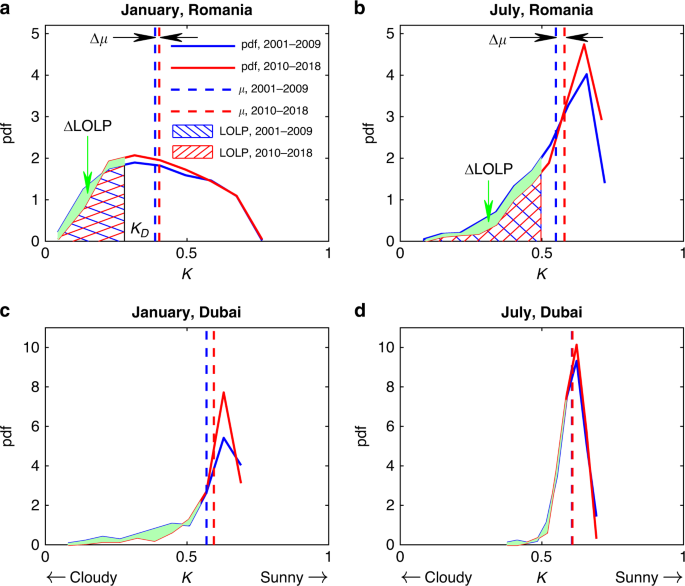

We begin our investigation with an analysis of the clearness index, K , defined as the ratio between the near-surface global horizontal irradiance (GHI, including direct and diffuse irradiance) and the corresponding extraterrestrial horizontal irradiance (see “Methods” section). This index accounts for the scattering, absorption, and reflection of solar radiation from all optically active constituents in the atmosphere, such as clouds and aerosols, and is often used in solar energy industry 23 , 24 , 25 , 26 . For example, we consider Southeastern Romania’s case, where climate change has shown strong regional impacts 27 and the case of Dubai, UAE, which is pursuing an ambitious plan to foster solar energy development in the region 28 . Romania and UAE, located in the continental and desert climatic zones, also have two contrasting cloud seasonality (see Supplementary Fig. 1 ) and drastically different solar energy production potentials. We use satellite data from Clouds and the Earth’s Radiant Energy System (CERES), which are based on column-model estimates and have been already used for solar power assessment 29 , 30 . Such multi-decadal records allow us to characterize the empirical distributions of daily K . As can be seen in Fig. 1 , the K distributions for larger mean values (denoted as μ and also referred to as the mean clearness index) tend to have longer left tails, which are associated with the weaker solar radiation and lower power generation.

The distribution of clearness index ( K ) derived from the CERES data in ( a , c ) January and ( b , d ) July during 2001–2009 (blue lines) and during 2010–2018 (red lines) in ( a , b ) Southern Romania and ( c, d ) Dubai. The hatched areas indicate the probability when power generation does not meet the demand, the loss-of-load probability (LOLP). The averages of clearness index are marked by the vertical dash lines and the values are reported in Supplementary Table 1 . Source data are provided as a Source Data file.

From the K distribution, the LOLP of a solar power plant operating at daily basis (e.g., the Tesla’s power plant at Kauai, Hawaii) can be estimated as the fraction of days with solar radiation lower than the demand value,

where f ( K ) is the probability density function (pdf) of K , and K D is the value of K that is just sufficient to meet the energy demand (see “Methods” section). LOLP is, therefore, the cumulative density function (CDF) of K at K D . This metric has long been used for designing a stand-alone (off-grid) photovoltaic power system 31 , 32 , 33 and is also a critical reference for evaluating a grid-connected system 20 . The constant demand K D in (1) is similar in spirit to the regulation from Northwest Grid of China, which was originally issued for coal plants considering their relatively constant power output but was recently extended to solar and wind power plants. A thorough characterization of the global solar power intermittency and its response to climate change using the LOLP is a fundamental starting point to assess the future reliability of photovoltaic.

Climate-change impacts on power reliability can be assessed by considering the change of LOLP during the lifespan of typical photovoltaic modules. Going back to the case of the Southern Romania, a solar plant designed under historical climate records of 2001–2009 is assumed to have a design LOLP, LOLP D , of 0.3. Over the following nine years (2010–2018), the mean of K increases in both January (Δ μ = 0.015) and July (Δ μ = 0.03), which may be associated with the change of climate seasonality 34 . The corresponding values of LOLP drop from the design value of 0.3 to 0.27 in winter (ΔLOLP = −0.03) and to 0.21 in summer (ΔLOLP = −0.09), respectively (see the hatched and shaded areas in Fig. 1a, b ). For the case in Dubai, aerosol optical depth trends 35 may account for the increase of μ in winter, leading to a decrease of LOLP (Fig. 1c ), while the monthly mean clearness index remains relatively constant in summer (Fig. 1d ). The comparisons between these two periods (2001–2009 and 2010–2018) objectively quantify not only the increase in mean surface solar radiation, but also the increase in its reliability.

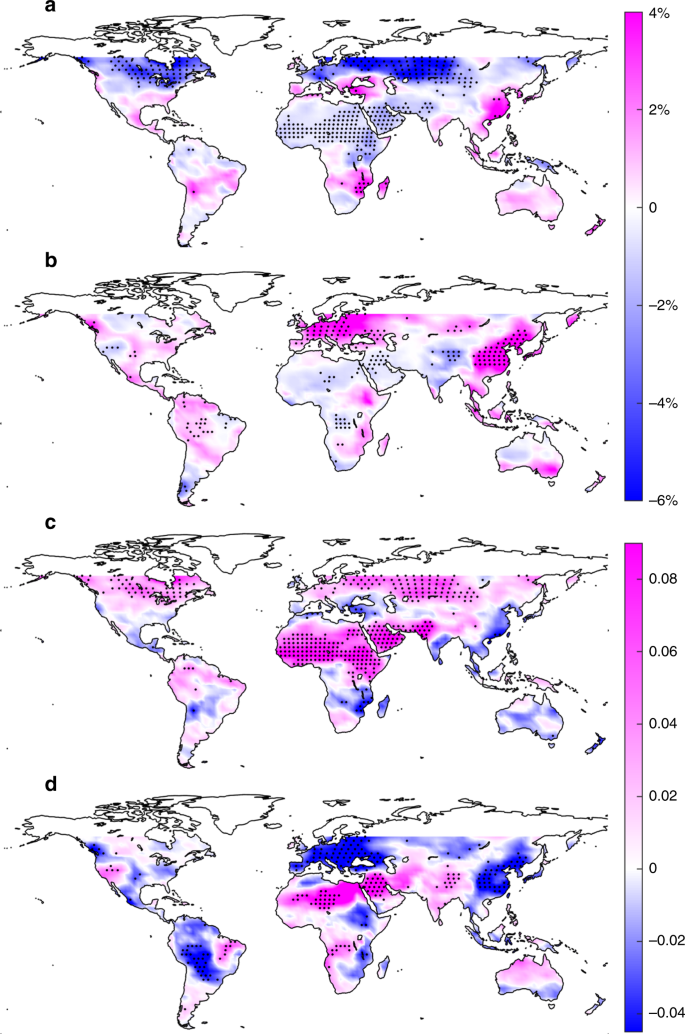

With this methodology, we now move to the future climate scenarios and use climate model outputs (see “Methods” section) to calculate the changes of μ and LOLP between 2006–2015 and 2041–2050, consistently with the typical lifespan of photovoltaic modules. As shown in Fig. 2a, b and in agreement with previous studies 15 , the change of solar radiation is evident in some regions and show marked seasonal variations. The solar radiation in Europe is projected to decrease in January and increase in July, which may be associated with the projected changes in rainfall seasonality and the corresponding cloud variations 34 . The decrease in solar radiation in the Middle East may be associated with large-scale circulation 36 , cloudiness trends 37 , or the positive trends of aerosol optical depth as documented over large parts of the Middle East for the period 2001–2012 35 .

The color at each grid point represents the ensemble means of ( a , b ) the relative change of mean clearness index (Δ μ / μ ) and ( c , d ) the change of loss-of-load probability (ΔLOLP) between 2006–2015 and 2041–2050 in the month of ( a , c ) January and ( b , d ) July from 11 climate model outputs. The LOLP during 2006–2015 (i.e., design LOLP) is set as 0.3; maps with other design LOLP show similar patterns (see Supplementary Figs. 2 and 3 ). The dots show the ensemble mean of the corresponding variables are statistically different than zero, suggesting consistent variations of solar radiation or reliability from most climate models ( t -test, 5% significance level; statistics of the sign of the changes are given in Supplementary Figs. 4 – 6 ). Source data are provided as a Source Data file.

This redistribution of the Earth’s energy and shifts in climate seasonality 38 have direct impacts on solar power reliability as quantified by the corresponding variations of LOLP (see Fig. 2c, d ). Although it is apparent that increasing solar radiation (Δ μ > 0) often leads to more reliable power output (ΔLOLP < 0), this relationship is clearly nonlinear. For example, the slight decrease of solar radiation in the Middle East and Northern Africa results in a significant increase of LOLP; an increase of solar radiation in the west of Amazon rainfall forest in July leads to a sharp decrease of LOLP; strong variations in both radiation and power reliability are shown in the Northern United States in January. In what follows, we will investigate this nonlinear relationship to quantitatively link the previous reports on mean solar radiation to one of our major concerns on power reliability.

Theoretical framework for power reliability

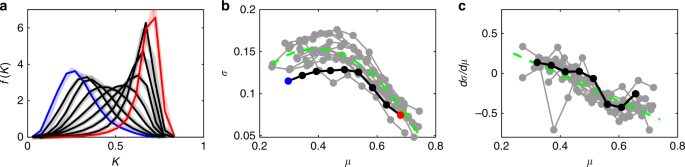

The case studies in Fig. 1 and geographical patterns in Fig. 2 suggest that LOLP may be linked to the distribution of K , which in the solar industry is often associated with the mean clearness index, μ 39 , 40 . To systematically and theoretically assess this linkage, we consider in detail satellite data as well as climate model outputs under the historical climate conditions. We obtained the statistics of K from all regions over the world with μ ranging from 0.3 to 0.7 with a binning interval of 0.05 (see dark color curves in Fig. 3a and Supplementary Fig. 7 ). As can be seen, f ( K ) tends to be positively skewed in regions with smaller μ and negatively skewed in regions with larger μ (see Fig. 3a ). Since the diffuse radiation has the largest variations for moderate K 39 , which includes direct and diffuse radiation, it is logical to expect σ first increases and then decreases with rising μ as presented in Fig. 3b . Overall, such empirical distributions even under changing climate conditions turn out to be well described by beta distributions (see “Methods” section).

a Probability density functions (pdf) of daily clearness index ( K ) in different regions over the world (binning width of 0.05) from the satellite data in January during 2001–2009 (dark color) and during 2010–2018 (light color). b Relationship between mean ( μ ) and standard deviation ( σ ) of daily K . The black/blue/red dots correspond to the lines in the a ; the grey dots are from 11 climate model outputs during 2006–2015; the dash green curve shows the best quadratic fit. c dσ / dμ calculated as the derivative of the corresponding σ ~ μ relationship in ( b ). Source data are provided as a Source Data file.

One may wonder whether these characteristics can vary in response to changing climates. To address this point, we checked the statistics of K at different periods (see the light-color curves in Fig. 3a , Supplementary Figs. 7 and 8 ). The results show that the distributions of K appear identical and the μ ~ σ relationships almost remain unchanged. These behaviors essentially describe how the intermittency of solar radiation (i.e., σ ) will adjust after the change of mean solar radiation (i.e., μ ), providing valuable information for solar power planning and management.

The invariant characteristics of K allow us to link Δ μ / μ to ΔLOLP between different periods and thus, in turn, to obtain power-reliability information from previous reports on long-term mean solar radiation. Operationally, this can be accomplished by Taylor expanding Eq. ( 1 ) to first order as

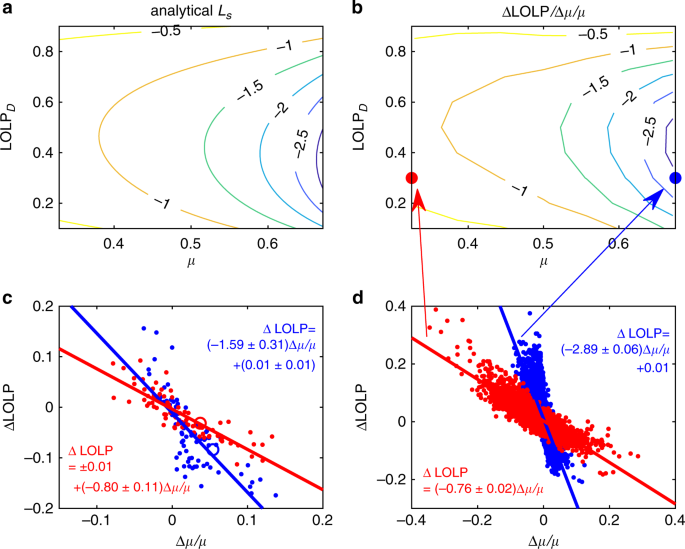

where L s is the sensitivity of LOLP to μ and can be derived analytically for the beta distribution of K (see “Methods” section), and the change of μ in percentage format is usually consistent with other reports. In Eq. ( 2 ), the first term evaluates the climate impacts in terms of LOLP, whereas the term in the bracket assesses the future solar radiation in the conventional apporach 15 , 16 , 17 , 18 , 19 . The relation between the two, ΔLOLP and Δ μ/μ , is clearly associated with the sensitivity parameter L s , a nonlinear function of μ and K D (or design LOLP, see Eq. ( 11 ) in “Methods” section). Particularly interesting is the fact that the absolute values of L s are larger in sunny regions/seasons with larger μ (see Fig. 4a ). This may be accounted for by the fact that the small perturbation of μ in sunny regions tends to have larger change in the variability of solar radiation (i.e., large absolute values of dσ / dμ , see right side of Fig. 3c ), which is obviously associated with the intermittency of solar energy. Since these are also the regions of the world where the largest solar plants are expected to be deployed in the future, this fact should be considered with great attention in reliability analysis.

Contour plots of L s is calculated ( a ) analytically from Eq. ( 2 ) and ( b ) numerically from climate model outputs. The red and blue dots in ( b ) are corresponding to the examples in ( d ), which compares the change of loss-of-load probability (LOLP) and the change of mean clearness index ( μ ) from 2006–2015 to 2041–2050 in January with design LOLP of 0.3 in regions where 0.3 < μ < 0.35 (red dots) and 0.65 < μ < 0.7 (blue dots) as projected by climate models. The red and blue lines are the corresponding best fit lines and their slopes (i.e., ΔLOLP / (Δ μ / μ )) numerically represent L s . ( c ) As in ( d ) but only for Bulgaria, Cyprus, Greece, Hungary, and Romania (i.e., region 7 defined in ref. 18 ) in January (red dots) and July (blue dots). The red and blue circles correspond to the example of Southern Romania in Fig. 1 . Source data are provided as a Source Data file.

Climate model outputs corroborate the previous analytical results. Figure 4d shows Δ μ / μ and ΔLOLP between 2006–2015 and 2041–2050 for given values of μ and design LOLP. The slopes of these two quantities are reported in Fig. 4b , showing similar patterns as their analytical counterparts (Fig. 4a ).

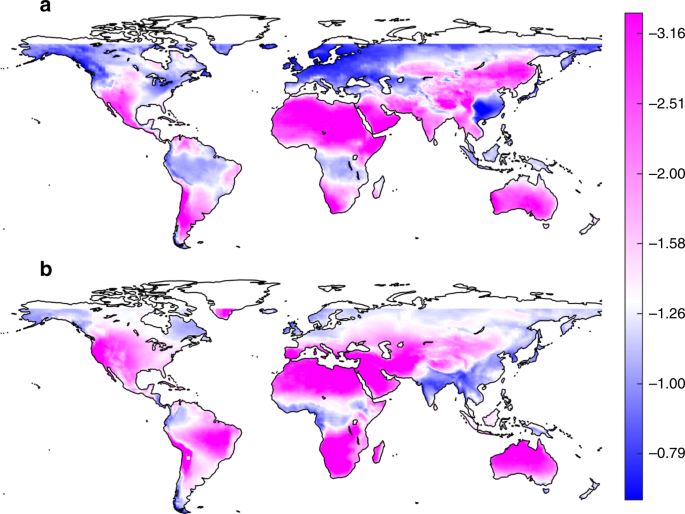

With the obtained nonlinear function of L s , one can readily infer the power reliability. To facilitate this, we mapped the analytical solution of L s in Fig. 4a to each location over the world with monthly mean clearness index from CERES data (see Fig. 5 and Supplementary Figs. 9 and 10 ). These maps could serve as lookup tables to assess power reliability in future climates. For example, Fig. 5 shows that L s is approximately −0.8 in January and −1.6 in July in Southern Romania for a design LOLP of 0.3. The mean solar radiation in this region is projected to vary around −15~0% in winter and around −5~5% in summer toward the end of the century 18 . Multiplying these variations by L s , one can find the impacts of these variations on LOLP (i.e., 0~12% in winter and −8~8% in summer). While the winter season has larger variations in solar radiation, it also has a small absolute value of L s so that the impacts on future power reliability in winter are reduced. This analysis is corroborated by the results from climate-model outputs as shown in Fig. 4c , which suggests larger spread of ΔLOLP but slightly smaller change of Δ μ / μ in summer in the surrounding of Romania.

This sensitivity in ( a ) January and ( b ) July is obtained from analytical solutions with design LOLP of 0.3 and solar radiation climatology from CERES. Source data are provided as a Source Data file.

The heterogeneous distribution of LOLP sensitivity in Fig. 5 essentially stems from the nonlinear relationship between μ and σ , which remains relatively constant under changing climates. Lower absolute values of L s with smaller clearness index suggest that the solar power in humid subtropics may have lower potential for large variability in future climates. This is consistent with the observed σ ~ μ relationship in Fig. 3b , where these slopes are flatter for smaller μ . Meanwhile, the humid subtropics are predicted to have relatively more solar radiation in the future climate scenarios 15 , 17 . The multiplication of small negative L s with positive Δ μ yields small but negative ΔLOLP, suggesting slightly higher power reliability. On the other hand, the arid hot regions are predicted to have less solar radiation but could yield much lower power reliability due to the strong LOLP sensitivity.

Our proposed framework may be further extended to diagnose the impacts of power storage, which is regarded as one of the most important solutions to the intermittency problems. Power storage smooths the power output to provide reliable energy. In our analysis, this effect may be considered by reducing the daily variability of future solar radiation and evaluating its impacts on LOLP (see “Methods” section). As expected, solar radiation with reduced variability has smaller LOLP, showing that increased storage can be used to mitigate the intermittency’s impacts in most parts of the world. However, this may not be sufficient in a few regions such as the Middle East (see Supplementary Fig. 11 ). When mean solar radiation is significantly reduced as predicted by climate models, it may require increasing both the power storage capacity and solar module size.

To investigate more detailed grid operation and conduct cost-benefit analysis of various mitigation strategies, the proposed framework may be extended by statistically downscaling the daily solar radiation to the hourly timescale 39 , 41 and involving multiple power sectors for power generation, storage, transmission, distribution, marketing, and technology development 1 , 2 . Our framework could also be used to analyze the temperature impacts on power reliability (see “Methods” section), although it is argued that the temperature impacts on photovoltaic power generation appear much weaker than the solar radiation impacts over the lifespan of photovoltaic modules 36 .

In summary, our results have shown how the impacts of this radiation change on power reliability could be significant due to the large absolute values of LOLP sensitivity, which had not emphasized previously. The sensitivity analysis points towards a tradeoff between the mean solar radiation that quantifies the total potential solar power and the power reliability, which being related to intermittency remains a major concern in the absence of large power storage options. This contrasting behavior between solar power availability and reliability requires special attention in assessments of future solar energy scenarios.

Clearness index (K)

The daily clearness index, K , is defined as

where T is the length of 1 day, GHI is the near-surface global horizontal irradiance, which is the sum of the direct and diffuse irradiance, and EHI the extraterrestrial horizontal irradiance. Daily GHI are obtained from CERES SYN1deg during 2001–2018 and from 11 climate model outputs (ACCESS1.3, BCC-CSM1.1 m, CanESM2, CCSM4, CMCC-CMS, CSIRO-Mk3.6.0, EC-EARTH, GFDL-CM3, INM-CM4, IPSL-CM5A, and MPI-ESM) in “rcp45” experiment during 2006–2015 and 2041–2050. All these data have been used to obtain the empirical distributions of K for calculating the loss-of-load probability as explained next.

Loss-of-load probability (LOLP)

The photovoltaic power output is related to the incident solar radiation and other factors controlling the solar cell efficiency 15 . Each month, the Sun’s declination angle has small variations; the daily incident solar radiation on a fixed or tracking array can be approximated as a monotonic function of daily clearness index 42 . Factors such as soiling and tree shading on solar modules could have notable impacts on power generation but can be controlled by regular maintanence. The solar cell efficiency factors such as air temperature and wind speed usually have only secondary impacts and are discussed in the following “Methods” section. Regarding climate change impacts, the incident solar radiation has been identified as the dominant factor for photovoltaic power generation. For this reason, we model the power output as a monotonic function of the clearness index, say p = g ( K ). This function can be used to estimate the LOLP. Similarly to the off-grid version of a photovoltaic software 43 , 44 , LOLP can be defined as the fraction of days when daily energy supply ( p ) is lower than the daily demand ( p D ). We obtain LOLP as the derived distribution of K ,

where K D is the specific value of K that is just enough to generate the demanding energy p D , f (·) and F (·) are the probability and cumulative density function of K . These functions are estimated from multi-year historical climate records, and thus the corresponding LOLP already captures the interannual variability of daily power generation. Such estimates are referred to as design LOLP, LOLP D . For the lifespan of typical photovoltaic modules (20–30 years), one can then quantify the climate impacts on power reliability as the change of LOLP from its design value.

LOLP sensitivity ( L s )

The distributions of K enters the LOLP expression in Eq. ( 4 ). As presented in Fig. 3a , the distribution of K tends to be positively skewed for smaller mean value of K (denoted as μ ) and negatively skewed for larger μ . These behaviors may be described as beta distributions naturally bounded between 0 and 1. This is confirmed by the results of the Kolmogorov-Smirnov goodness-of-fit tests over most regions in the world in different climate zones (see Supplementary Fig. 12 and Supplementary Table 2 )

where β 1 and β 2 are the shape parameters. Note that this beta distribution is a parsimonious choice which we prefer to other unbounded distributions (e.g., Weibull and extreme value distributions) used in the literature 45 , 46 . We stress however that our framework is not limited to the use of beta distributions but can easily adopt other distributions if they appear more suitable in some regions (e.g., Australia and Western Sahara). These shape parameters can be expressed by the mean ( μ ) and standard deviation ( σ ) of the distribution 47 ,

As described in Fig. 3b , the standard deviation may be modeled as a function of mean (e.g., \(\sigma = - 0.83\mu ^2 + 0.65\mu + 0.03\) , the best quadratic fit) so that the distribution of K can be written as

Substituting ( 8 ) into ( 4 ) and performing a Taylor expansion to first order yields

where \(F_b( \cdot )\) is the cumulative beta distribution and K D is equivalent to design LOLP,

The corresponding analytical solutions of L s (Fig. 4a ) are very similar to its counterpart calculated numerically as \({\Delta}{\mathrm{LOLP}}/({\Delta}\mu /\mu )\) (Fig. 4b ). The approximation of Taylor expansion to the first order is justified by the fact that L s is relatively constant for a small perturbation of μ (see Fig. 4a ). Clearly, one can insert other distributions suitable in some specific regions into Eqs. ( 4 ) and ( 9 ) to obtain the corresponding analytical expression for the sensitivity of power reliability.

Impacts of temperature change on power reliability

Temperature influences the energy conversion efficiency and can have significant impacts on power generation in hot climates 48 . It is estimated that photovoltaic power output reduces by 0.45% for each degree increase in temperature 49 , 50 . Therefore, we may treat the temperature rising as equivalent to the increase of power requirement in our original framework and redefine the parameter K D as

where the temperature factor, γ T , is about 0.0045/K, T r is the reference temperature, and K D , r is the specific value of K that is just enough to generate the demanding energy at the reference temperature. With this change, the corresponding LOLP becomes,

The change of LOLP from current to future climate conditions can be expressed as

This expression suggests that the change of LOLP has two parts. This first part is in Eq. ( 9 ) and the second part can be obtained analytically by substituting Eq. ( 5 ) into Eq. ( 15 ). The sensitivity for temperature, L T , is always positive (see Eq. ( 15 )), meaning that rising temperature increases the LOLP.

Impact of power storage on power reliability

Power storage at multiday timescale, if feasible, would obviously help improve power reliability. To explore this issue within the scope of the present analysis, as a proof of concept, we simply smoothed the daily clearness index to roughly estimate the impacts of power storage on power reliability

where the clearness index K is smoothed into K b . The corresponding standard deviation becomes

where the coefficient b controls the reduction of the variability. This coefficient b is set as 0.75 and 0.5 for two future scenarios corresponding to the 25 and 50% variability mitigation.

We applied Eq. ( 17 ) to recalculate the clearness index from 11 climate model outputs during 2041–2050, which were then used to numerically calculate the LOLP. We showed the change of LOLP with no variability mitigation, 25% mitigation, and 50% mitigation in Supplementary Fig. 11 . Reducing the variability leads to a decrease of LOLP and thus more reliable power output as expected. This is generally sufficient for addressing some of the challenges of intermittent solar power and the uncertainties related to climate change. In some regions, however, climate models also predict decreasing trends of mean solar radiation, which may not be compensated only by the power storage. This is the case of the Middle East, where solar power is projected to be significantly reduced, so that LOLP increases even with variability mitigation measures (see Supplementary Fig. 11 ).

Data accuracy

To provide information regarding the data accuracy, we compared these satellite data and climate model outputs with the data from National Solar Radiation Database (NSRDB). The latter are produced by ground observations, satellite data, and meteorological models and are arguably one of the most reliable datasets for assessing the long-term spatial and temporal variability of the solar resource 51 . It should be noted that validating the global solar irradiance and surface energy balance is one of the biggest challenges in the climate science community 52 , 53 .

Two typical outputs with different assimilation models, METSTAT and SUNY, are achieved in NSRDB [ https://rredc.nrel.gov/solar/old_data/nsrdb/ ] and both are recommended by NREL. We compared SUNY and METSTAT during 2001–2010 when both products are available (see Supplementary Fig. 13a, b ). Of 1415 sites over the United States (sites with missing data are excluded), the root mean square errors (RMSE) between these two outputs are around 0.05, which may be considered as the systematic biases from NSRDB. When further compared these measurements with satellite data (CERES SYN) in the same locations during the same period (see Supplementary Fig. 13c–f ), one finds similar ranges of RMSE, suggesting that the satellite products are as accurate as these reliable data.

We then compared the long-term clearness index from the satellite data and the climate model outputs during 2006–2015 averaged at 280 km equal-area grids over the world (see Supplementary Figs. 14 , 15 , and Supplementary Table 3 ). The RMSE for some climate models (e.g., CCSM, GFDL) are similar to these SUNY-METSTAT differences from NSRDB, while for others the RMSE is at least of the same order of magnitude.

Besides these data comparison, it is also important to note that aerosol is a key climate component and future aerosol emissions are usually described as different scenarios such as Representative Concentration Pathways (RCPs) 54 . Our results are from RCP45, which includes the projected decline in aerosols during the 21th century because of the emission controls 55 . While the future aerosol emissions are prescribed, not all models include their indirect effects related to the aerosol-cloud interaction (see Supplementary Table 4 ), which could have an impact on cloud formation and the prediction of solar radiation 56 . However, these indirect effects do not seem to have strong impacts on the relationship between the mean and standard deviation of the radiation (see Supplementary Fig. 8 ), a key feature in our analysis of power reliability.

Data availability

The climate model data were downloaded from the fifth phase of the Coupled Model Intercomparison Project website [ http://cmip-pcmdi.llnl.gov ]. The satellite data from CERES were obtained from website [ https://ceres.larc.nasa.gov/order_data.php ]. Source data are provided with this paper.

Code availability

Matlab code for calculating the analytical solutions of power reliability sensitivity is available at [ https://github.com/jy8/solar ]; other codes are available upon request.

Fripp, M. Switch: a planning tool for power systems with large shares of intermittent renewable energy. Environ. Sci. Technol. 46 , 6371–6378 (2012).

ADS CAS PubMed Google Scholar

He, G. et al. SWITCH-China: a systems approach to decarbonizing China’s power system. Environ. Sci. Technol. 50 , 5467–5473 (2016).

Perez, R. et al. Achieving very high PV penetration—the need for an effective electricity remuneration framework and a central role for grid operators. Energy Policy 96 , 27–35 (2016).

Google Scholar

Northwest China Energy Regulatory. Regulation for grid-connected power plants in Northwest regions. http://xbj.nea.gov.cn/website/Aastatic/news-196276.html (2018).

Ying, L. Northwest photovolatic power plants received $0.27 billion ticket for the first half year of 2019. CNGOLD https://energy.cngold.org/c/2019-09-19/c6584966.html (2019).

Guangfumen. Penalty doubled: photovoltaic and wind power plants in Qinghai receive 17 million tickets in January. Sohu http://www.sohu.com/a/314591748_609294 (2019).

KIUC. Renewables | Kauai Island Utility Cooperative. http://website.kiuc.coop/renewables (2019).

Golson, J. Tesla built a huge solar energy plant on the island of Kauai. The Verge https://www.theverge.com/2017/3/8/14854858/tesla-solar-hawaii-kauai-kiuc-powerpack-battery-generator (2017).

Klippenstein, M. Tesla’s solar and battery project in Hawaii: we do the math. Green Car Reports https://www.greencarreports.com/news/1112800_teslas-solar-and-battery-project-in-hawaii-we-do-the-math (2017).

Dessler, A. E. A determination of the cloud feedback from climate variations over the past decade. Science 330 , 1523–1527 (2010).

Boucher, O. et al. Clouds and Aerosols. in Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Chang e (eds. Stocker, T. F. et al.) 571–658 (Cambridge University Press, 2013).

Bloomfield, H. C., Brayshaw, D. J., Shaffrey, L. C., Coker, P. J. & Thornton, H. E. Quantifying the increasing sensitivity of power systems to climate variability. Environ. Res. Lett. 11 , 124025 (2016).

ADS Google Scholar

Yin, J. & Porporato, A. Diurnal cloud cycle biases in climate models. Nat. Commun. 8 , 2269 (2017).

ADS PubMed PubMed Central Google Scholar

Yin, J. & Porporato, A. Radiative effects of daily cycle of cloud frequency in past and future climates. Clim. Dyn. 54 , 1625–1637 (2020).

Crook, J. A., Jones, L. A., Forster, P. M. & Crook, R. Climate change impacts on future photovoltaic and concentrated solar power energy output. Energy Environ. Sci. 4 , 3101–3109 (2011).

Bartos, M. D. & Chester, M. V. Impacts of climate change on electric power supply in the Western United States. Nat. Clim. Change 5 , 748–752 (2015).

Wild, M., Folini, D., Henschel, F., Fischer, N. & Müller, B. Projections of long-term changes in solar radiation based on CMIP5 climate models and their influence on energy yields of photovoltaic systems. Sol. Energy 116 , 12–24 (2015).

Jerez, S. et al. The impact of climate change on photovoltaic power generation in Europe. Nat. Commun. 6 , 10014 (2015).

ADS CAS PubMed PubMed Central Google Scholar

Bazyomo, S. D. Y. B., Agnidé Lawin, E., Coulibaly, O. & Ouedraogo, A. Forecasted changes in west africa photovoltaic energy output by 2045. Climate 4 , 53 (2016).

NERC. Probabilistic Adequacy and Measures . (NERC, 2018).

Ming, B. et al. Optimizing utility-scale photovoltaic power generation for integration into a hydropower reservoir by incorporating long- and short-term operational decisions. Appl. Energy 204 , 432–445 (2017).

DeCarolis, J. F. & Keith, D. W. The economics of large-scale wind power in a carbon constrained world. Energy Policy 34 , 395–410 (2006).

Aguiar, R. J., Collares-Pereira, M. & Conde, J. P. Simple procedure for generating sequences of daily radiation values using a library of Markov transition matrices. Sol. Energy 40 , 269–279 (1988).

Lambert, T., Gilman, P. & Lilienthal, P. Micropower system modeling with HOMER. In Integr. Altern. Sources Energy (eds. Farret, F. A., & Simoes, M. G.) 379–418 (John Wiley & Sons, 2016).

Yadav, A. K. & Chandel, S. S. Tilt angle optimization to maximize incident solar radiation: a review. Renew. Sustain. Energy Rev. 23 , 503–513 (2013).

Bett, P. E. & Thornton, H. E. The climatological relationships between wind and solar energy supply in Britain. Renew. Energy 87 , 96–110 (2016).

Kayser-Bril, N. Europe is getting warmer, and it’s not looking like it’s going to cool down anytime soon. European Data Journalism Network https://www.europeandatajournalism.eu/eng/News/Data-news/Europe-is-getting-warmer-and-it-s-not-looking-like-it-s-going-to-cool-down-anytime-soon (2018).

IRENA. Renewable Energy Market Analysis: GCC 2019 (IRENA, 2019).

Chandler, W. S., Whitlock, C. H. & Stackhouse, P. W. NASA climatological data for renewable energy assessment. J. Sol. Energy Eng. 126 , 945–949 (2004).

Li, X., Wagner, F., Peng, W., Yang, J. & Mauzerall, D. L. Reduction of solar photovoltaic resources due to air pollution in China. Proc. Natl Acad. Sci. 114 , 11867–11872 (2017).

Barra, L., Catalanotti, S., Fontana, F. & Lavorante, F. An analytical method to determine the optimal size of a photovoltaic plant. Sol. Energy 33 , 509–514 (1984).

Chapman, R. N. Sizing Handbook for Stand-alone Photovoltaic/Storage Systems . (Sandia National Laboratories, 1987).

Egido, M. & Lorenzo, E. The sizing of stand alone PV-system: a review and a proposed new method. Sol. Energy Mater. Sol. Cells 26 , 51–69 (1992).

CAS Google Scholar

Pascale, S., Lucarini, V., Feng, X., Porporato, A. & Hasson, Sul Projected changes of rainfall seasonality and dry spells in a high greenhouse gas emissions scenario. Clim. Dyn. 46 , 1331–1350 (2016).

Klingmüller, K., Pozzer, A., Metzger, S., Stenchikov, G. L. & Lelieveld, J. Aerosol optical depth trend over the Middle East. Atmos. Chem. Phys. 16 , 5063–5073 (2016).

Gaetani, M. et al. The near future availability of photovoltaic energy in Europe and Africa in climate-aerosol modeling experiments. Renew. Sustain. Energy Rev. 38 , 706–716 (2014).

Yousef, L. A. et al. Cloud cover over the Arabian Peninsula from global remote sensing and reanalysis products. Atmos. Res. 238 , 104866 (2020).

Feng, X., Porporato, A. & Rodriguez-Iturbe, I. Changes in rainfall seasonality in the tropics. Nat. Clim. Change 3 , 1–5 (2013).

Liu, B. Y. H. & Jordan, R. C. The interrelationship and characteristic distribution of direct, diffuse and total solar radiation. Sol. Energy 4 , 1–19 (1960).

Klein, S. A. & Beckman, W. A. Loss-of-load probabilities for stand-alone photovoltaic systems. Sol. Energy 39 , 499–512 (1987).

Hollands, K. G. T. & Huget, R. G. A probability density function for the clearness index, with applications. Sol. Energy 30 , 195–209 (1983).

Gunerhan, H. & Hepbasli, A. Determination of the optimum tilt angle of solar collectors for building applications. Build. Environ. 42 , 779–783 (2007).

Huld, T., Moner-Girona, M. & Kriston, A. Geospatial analysis of photovoltaic mini-grid system performance. Energies 10 , 218 (2017).

Huld, T. PVMAPS: Software tools and data for the estimation of solar radiation and photovoltaic module performance over large geographical areas. Sol. Energy 142 , 171–181 (2017).

Markvart, T., Fragaki, A. & Ross, J. N. PV system sizing using observed time series of solar radiation. Sol. Energy 80 , 46–50 (2006).

ADS CAS Google Scholar

Kaplani, E. & Kaplanis, S. A stochastic simulation model for reliable PV system sizing providing for solar radiation fluctuations. Appl. Energy 97 , 970–981 (2012).

Davison, A. C. Statistical Models . vol. 11 (Cambridge University Press, 2003).

Dubey, S., Sarvaiya, J. N. & Seshadri, B. Temperature dependent photovoltaic (PV) efficiency and its effect on PV production in the world—a review. Energy Procedia 33 , 311–321 (2013).

Fell, A. et al. Input parameters for the simulation of silicon solar cells in 2014. IEEE J. Photovolt. 5 , 1250–1263 (2015).

Patt, A., Pfenninger, S. & Lilliestam, J. Vulnerability of solar energy infrastructure and output to climate change. Clim. Change 121 , 93–102 (2013).

Sengupta, M. et al. The national solar radiation data base (NSRDB). Renew. Sustain. Energy Rev. 89 , 51–60 (2018).

Trenberth, K. E., Fasullo, J. T. & Kiehl, J. Earth’s global energy budget. Bull. Am. Meteorol. Soc. 90 , 311–323 (2009).

Wild, M. et al. The energy balance over land and oceans: an assessment based on direct observations and CMIP5 climate models. Clim. Dyn. 44 , 3393–3429 (2015).

Moss, R. H. et al. The next generation of scenarios for climate change research and assessment. Nature 463 , 747–756 (2010).

Rotstayn, L. D. et al. Declining aerosols in CMIP5 projections: effects on atmospheric temperature structure and midlatitude jets. J. Clim. 27 , 6960–6977 (2014).

Chylek, P. et al. Indirect aerosol effect increases CMIP5 models’ projected arctic warming. J. Clim. 29 , 1417–1428 (2016).

Download references

Acknowledgements

We would like to thank Professors Robert Socolow and Tiejian Li for their constructive comments on this work. J.Y. acknowledges support from the National Natural Science Foundation of China (41877158, 51739009), NUIST startup funding (1441052001003), Jiangsu distinguished faculty program, and NUIST’s supercomputing center. A.P. acknowledges support from the USDA Agricultural Research Service cooperative agreement 58-6408-3-027; and National Science Foundation (NSF) grants EAR-1331846, EAR-1316258, FESD EAR-1338694, and the Carbon Mitigation Initiative at Princeton University. A.M. acknowledges support from the Khalifa University Competitive Internal Research Award, CIRA-2018-102.

Author information

Authors and affiliations.

School of Hydrology and Water Resources, Nanjing University of Information Science and Technology, Nanjing, 210044, China

Masdar Institute, Khalifa University of Science and Technology, PO Box 54224, Abu Dhabi, UAE

Annalisa Molini

Department of Civil Infrastructure and Environmental Engineering, Khalifa University of Science and Technology, PO Box 127788, Abu Dhabi, UAE

Department of Civil and Environmental Engineering, Princeton University, Princeton, NJ, 08544, USA

Amilcare Porporato

Princeton Environmental Institute, Princeton University, Princeton, NJ, 08544, USA

You can also search for this author in PubMed Google Scholar

Contributions

J.Y., A.M., and A.P. conceived and designed the study. J.Y. wrote an initial draft of the paper, to which all authors contributed edits throughout.

Corresponding author

Correspondence to Amilcare Porporato .

Ethics declarations

Competing interests.

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks Georgiy Stenchikov and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary information, peer review file, source data, source data, rights and permissions.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Cite this article.

Yin, J., Molini, A. & Porporato, A. Impacts of solar intermittency on future photovoltaic reliability. Nat Commun 11 , 4781 (2020). https://doi.org/10.1038/s41467-020-18602-6

Download citation

Received : 29 January 2020

Accepted : 28 August 2020

Published : 22 September 2020

DOI : https://doi.org/10.1038/s41467-020-18602-6

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

This article is cited by

Accurate nowcasting of cloud cover at solar photovoltaic plants using geostationary satellite images.

- Shengjie Jia

Nature Communications (2024)

Unsupervised discovery of thin-film photovoltaic materials from unlabeled data

- Zhilong Wang

npj Computational Materials (2021)

By submitting a comment you agree to abide by our Terms and Community Guidelines . If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

Sign up for the Nature Briefing newsletter — what matters in science, free to your inbox daily.

Emerging Trends in Mechanical and Industrial Engineering pp 251–275 Cite as

Recent Developments and Challenges in Solar Harvesting of Photovoltaic System: A Review

- Alok Sanyal 13 ,

- MD Faiyaz Ahmed 13 &

- J. C. Mohanta 13

- First Online: 01 January 2023

670 Accesses

1 Citations

Part of the book series: Lecture Notes in Mechanical Engineering ((LNME))

Solar energy is a green and renewable energy source which is commonly used in photovoltaic and thermal cells. Solar power systems are among the fastest developing alternatives to fossil fuels, extending to commercial and industrial applications. As the position of the sun and other significant aspects fluctuate constantly, only a percentage of the sun’s energy potential is a harness. Solar trackers are ideal for enhancing solar panels’ conversion effectiveness by following the sun’s position all day long. This paper is an overview to take full advantage of the PV system by enhancing the solar panel’s conversion efficiency and choosing effective solar tracking. This review describes the basics of PV material and their achieved efficiency for laboratory, commercial, and industrial applications. The key objective of this paper is to create a roadmap of sun-tracking methods, their pros and cons to build an effective, low-cost, and reliable PV system for maximum solar energy harvesting. The study revealed that the active dual-axes closed-loop control based on non-conventional control algorithms could be the best tracking method to maximize the PV system’s output.

- Photovoltaic system

- PV materials

- Solar tracking

- Azimuth/elevation angles

- Control strategy

This is a preview of subscription content, log in via an institution .

Buying options

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Available as EPUB and PDF

- Compact, lightweight edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

Tax calculation will be finalised at checkout

Purchases are for personal use only

Hultman NE (2007) Can the world wean itself from fossil fuels? Curr Hist 106(703):376

Article Google Scholar

Rotmans J, Swart R (1990) The gloomy greenhouse: should the world phase out fossil fuels? Environ Manage 14(3):291–296

Sampaio PGV, González MOA (2017) Photovoltaic solar energy: conceptual framework. Renew Sustain Energy Rev 74:590–601

Ploetz R, Rusdianasari R, Eviliana E (2016) Renewable energy: advantages and disadvantages. In: Proceeding forum in research, science, and technology (FIRST) 2016. Politeknik Negeri Sriwijaya

Google Scholar

Ugli TJT (2019) The importance of alternative solar energy sources and the advantages and disadvantages of using solar panels in this process. Int J Eng Inf Syst (IJEAIS) 3(4)

Lakatos L, Hevessy G, Kovács J (2011) Advantages and disadvantages of solar energy and wind-power utilization. World Futures 67(6):395–408

Mohtasham J (2015) Renewable energies. Energy Procedia 74:1289–1297

IEA As we mark the Paris Agreement’s 5th anniversary, we continue to expand our work on energy and climate, IEA, Paris (2020)

Siecker J, Kusakana K, Numbi BP (2017) A review of solar photovoltaic systems cooling technologies. Renew Sustain Energy Rev 79:192–203

Maradin D (2021) Advantages and disadvantages of renewable energy sources utilization. Int J Energy Econ Policy 11(3):176–183

Nijs J, Sivoththaman S, Szlufcik J, De Clercq K, Duerinckx F, Van Kerschaever E, Einhaus R, Poortmans J, Vermeulen T, Mertens R (1997) Overview of solar cell technologies and results on high efficiency multicrystalline silicon substrates. Sol Energy Mater Sol Cells 48:199–217

Mousazadeh H, Keyhani A, Javadi A, Mobli H, Abrinia K, Sharifi A (2009) A review of principle and sun-tracking methods for maximizing solar systems output. Renew Sustain Energy Rev 13(8):1800–1818

FinsterC (1962) El Heliostato de la Universidad Santa Maria. Scientia 119:5–20

Saavedra A (1963) Diseño de un servo-mecanismo seguidor solar para un instrument registrador de la irradiación solar directa. Mem Univ Técnica Feder St Maria, Valpso, Chile

McFee R (1975) Power collection reduction by mirror surface nonflatness and tracking error for a central receiver solar power system. Appl Opt 14:1493–1502

Dorian ME, Nelson DH (1980) Solar tracking device. Google Patents

Badescu V (1985) The influence of certain astronomical and constructive parameters on the concentration of solar radiation with plane heliostats fields. Rev Phys Appl 20:711–733

Skouri S, Ali ABH, Bouadila S, Salah MB, Nasrallah SB (2016) Design and construction of sun tracking systems for solar parabolic concentrator displacement. Renew Sustain Energy Rev 60:1419–1429

Koussa M, Cheknane A, Hadji S, Haddadi M, Noureddine S (2011) Measured and modelled improvement in solar energy yield from flat plate photovoltaic systems utilizing different tracking systems and under a range of environmental conditions. Appl Energy 88:1756–1771

Sun J, Wang R, Hong H, Liu Q (2017) An optimized tracking strategy for small-scale double- axis parabolic trough collector. Appl Therm Eng 112:1408–1420

Sungur C (2009) Multi-axes sun-tracking system with PLC control for photovoltaic panels in Turkey. Renew Energy 34:1119–1125

Meral ME, Dincer F (2011) A review of the factors affecting operation and efficiency of photovoltaic based electricity generation systems. Renew Sustain Energy Rev 15(5):2176–2184

Green MA, Emery K, Hishikawa Y, Warta W, Dunlop ED (2015) Solar cell efficiency tables (version 45). Progress Photovolt: Res Appl 23(1):1–9

Pandey AK, Tyagi VV, Jeyraj A, Selvaraj L, Rahim NA, Tyagi SK (2016) Recent advances in solar photovoltaic systems for emerging trends and advanced applications. Renew Sustain Energy Rev 53:859–884

Kalogirou SA (2013) Solar energy engineering: processes and systems. Academic Press

Glunz SW, Feldmann F, Richter A, Bivour M, Reichel C, Steinkemper H, Benick J, Hermle M. The irresistible charm of a simple current flow pattern—25% with a solar cell featuring a full-area back

Richter A, Hermle M, Glunz SW (2013) Reassessment of the limiting efficiency for crystalline silicon solar cells. IEEE J Photovoltaics 3(4):1184–1191. https://doi.org/10.1109/JPHOTOV.2013.2270351

Green MA, Hishikawa Y, Warta W, Dunlop ED, Levi DH, Hohl-Ebinger J, Ho-Baillie AWH (2017) Solar cell efficiency tables (version 50). Prog Photovolt 25:668– 676

Stuckelberger M, Biron R, Wyrsch N, Haug FJ, Ballif C (2017) Progress in solar cells from hydrogenated amorphous silicon. Renew Sustain Energy Rev 76:1497–1523

Matsui T, Maejima K, Bidiville A, Sai H, Koida T, Suezaki T, Matsumoto M, Saito K, Yoshida I, Kondo M (2015) High-efficiency thin-film silicon solar cells realized by integrating stable a-Si: H absorbers into improved device design. Jpn J Appl Phys 54(8S1):08KB10

Feurer T, Reinhard P, Avancini E, Bissig B, Lockinger J, Fuchs P, Carron R, Weiss TP, Perrenoud J, Stutterheim S et al (2017) Progress in thin film CIGS photovoltaics—research and development, manufacturing, and applications. Prog Photovolt 25: 645–667

Ramanujam J, Singh UP (2017) Copper indium gallium selenide based solar cells—a review. Energy Environ Sci 10(6):1306–1319

Solar, First. First Solar sets world record for CdTe solar cell efficiency. 2015–01–08. http://investor.firstsolar . com/releases.cfm (2014)

Basol BM, McCandless B (2014) Brief review of cadmium telluride-based photovoltaic technologies. J Photonics Energy 4(1):040996

Yeoh ME, Chan KY (2021) A review on semi-transparent solar cells for real- life applications based on dye-sensitized technology. IEEE J Photovoltaics

Ji JM, Zhou H, Eom YK, Kim CH, Kim HK (2020) 14.2% efficiency dye‐ sensitized solar cells by co‐sensitizing novel thieno [3, 2‐b] indole‐based organic dyes with a promising porphyrin sensitizer. Adv Energy Mater 10(15): 2000124

Nozik AJ (2002) Quantum dot solar cells. Phys E 14(1–2):115–120

Sogabe T, Shen Q, Yamaguchi K (2016) Recent progress on quantum dot solar cells: a review. J Photonics Energy 6(4):040901

Brunetti V, Chibli H, Fiammengo R, Galeone A, Malvindi MA, Vecchio G, Cingolani R, Nadeau JL, Pompa PP (2013) InP/ZnS as a safer alternative to CdSe/ZnS core/shell quantum dots: in vitro and in vivo toxicity assessment. Nanoscale 5(1):307–317

Habibi M, Zabihi F, Ahmadian-Yazdi MR, Eslamian M (2016) Progress in emerging solution-processed thin film solar cells–Part II: Perovskite solar cells. Renew Sustain Energy Rev 62:1012–1103

"NREL efficiency chart”

Xue R, Zhang J, Li Y, Li Y (2018) Organic solar cell materials toward commercialization. Small 14(41):1801793

Cui Y, Yao H, Hong L, Zhang T, Tang Y, Lin B, Xian K, Gao B, An C, Bi P, Ma W (2020) Organic photovoltaic cell with 17% efficiency and superior processability. Nat Sci Rev 7(7):1239–1246

Frankl P, Nowak S, Gutschner M, Gnos S, Rinke T (2010) International energy agency technology roadmap: solar photovoltaic energy

Philipps SP, Bett AW, Horowitz K, Kurtz S (2015 Current status of concentrator photovoltaic (CPV) technology (No. NREL/TP-5J00–65130). National Renewable Energy Lab (NREL), Golden, CO (United States)

Mcconnell D (2011) Renewable energy technology cost review

Batayneh W, Bataineh A, Soliman I, Hafees SA (2019) Investigation of a single-axis discrete solar tracking system for reduced actuations and maximum energy collection. Autom Constr 98:102–109

Zhu Y, Liu J, Yang X (2020) Design and performance analysis of a solar tracking system with a novel single-axis tracking structure to maximize energy collection. Appl Energy 264:114647

Kuttybay N, Saymbetov A, Mekhilef S, Nurgaliyev M, Tukymbekov D, Dosymbetova G, Meiirkhanov A, Svanbayev Y (2020) Optimized single-axis schedule solar tracker in different weather conditions. Energies 13(19):5226

Geolounge (2014) Latitude and longitude. https://www.geolounge.com/latitudelongitude . Accessed 15 March

Karafil A, Ozbay H, Kesler M, Parmaksiz H (2015) Calculation of optimum fixed tilt angle of PV panels depending on solar angles and comparison of the results with experimental study conducted in summer in Bilecik, Turkey. In 2015 9th International conference on electrical and electronics engineering (ELECO). IEEE, pp 971-–976

Yilmaz S, Ozcalik HR, Dogmus O, Dincer F, Akgol O, Karaaslan M (2015) Design of two axes sun tracking controller with analytically solar radiation calculations. Renew Sustain Energy Rev 43:997–1005

Sawant A, Bondre D, Joshi A, Tambavekar P, Deshmukh A (2018) Design and analysis of automated dual axis solar tracker based on light sensors. In: 2018 2nd International conference on I-SMAC (IoT in social, mobile, analytics and cloud) (I-SMAC) I-SMAC (IoT in social, mobile, analytics and cloud) (I-SMAC), 2018 2nd international conference on. IEEE, pp 454–459

De Melo KB, De Paula BHK, Da Silva MK, Narváez DI, Moreira HS, Villalva MG, De Siqueira TG (2019) A study on the influence of locality in the viability of solar tracker systems. In: Congresso Brasileiro de Automática-CBA, vol 1, No. 1

Mpodi EK, Tjiparuro Z, Matsebe O (2019) Review of dual axis solar tracking and development of its functional model. Procedia Manuf 35:580–588

Kesava AAAEP, Lim W (2018) Triple-axis tracking control algorithm for maximizing solar energy harvesting on a moving platform. ARPN J Eng Appl Sci 13:4617–4624

Haider MR, Shufian A, Alam MN, Hossain MI, Islam R, Azim MA (2021) Design and implementation of three-axis solar tracking system with high efficiency. In: 2021 International conference on information and communication technology for sustainable development (ICICT4SD). IEEE, pp 1–5

Awad H, Moawad S, Atalla A (2018) Experimental comparison between microcontrollers and programmable logic controllers in sun tracking applications. In: 2018 twentieth international middle east power systems conference (MEPCON). IEEE, pp 58–63

Singh J (2019) Comparative analysis of existing latest microcontroller development boards. In: Emerging research in electronics, computer science and technology. Springer, Singapore, pp 1011–1025

Hassan R, Abubakar B (2020) Intelligent arduino based automatic solar tracking system using light dependent resistors (LDRs) and servo motor. Optics 9(2):13

Naif YH (2020) Design of Arduino-based dual axis solar tracking system. JAREE (J Adv Res Electr Eng) 4(2)

Elsherbiny MS, Anis WR, Hafez IM, Mikhail AR (2017) Design of single-axis and dual-axis solar tracking systems protected against high wind speeds. Int J Sci Technol Res 6(9):84–89

Chin CS, Babu A, McBride W (2011) Design, modeling and testing of a standalone single axis active solar tracker using MATLAB/Simulink. Renew Energy 36(11):3075–3090

Kanyarusoke KE, Gryzagoridis J, Oliver G (2015) Are solar tracking technologies feasible for domestic applications in rural tropical Africa? J Energy Southern Africa 26(1):86–95

Muhammad JYU, Jimoh MT, Kyari IB, Gele MA, Musa I (2019) A review on solar tracking system: a technique of solar power output enhancement. Eng Sci 4(1):1–11

Zulkafli RS, Bawazir AS, Amin NAM, Hashim MSM, Majid MSA, Nasir NFM (2018) Dual axis solar tracking system in Perlis, Malaysia. J Telecommun Electron Comput Eng (JTEC) 10(1–14):91–94

Brito MC, Po JM, Pereira D, Simoes F, Rodriguez R, Amador JC (2019) Passive solar tracker based in the differential thermal expansion of vertical strips. J Renew Sust Energy 11(4):043701

Algifri AH, Al-Towaie HA (2001) Efficient orientation impacts of box-type solar cooker on the cooker performance. Sol Energy 70(2):165–170

Yakup MABHM, Malik AQ (2001) Optimum tilt angle and orientation for solar collector in Brunei Darussalam. Renew Energy 24(2):223–234

Beshears DL, Capps GJ, Earl DD, Jordan JK, Maxey LC, Muhs JD, Leonard TM (2003) Tracking systems evaluation for the “hybrid lighting system”. Int Solar Energy Conf 36762:699–708

Grena R (2008) An algorithm for the computation of the solar position. Sol Energy 82(5):462–470

Mi Z, Chen J, Chen N, Bai Y, Fu R, Liu H (2016) Open-loop solar tracking strategy for high concentrating photovoltaic systems using variable tracking frequency. Energy Convers Manage 117:142–149

Fuentes-Morales RF, Diaz-Ponce A, Pena-Cruz MI, Rodrigo PM, Valentín- Coronado LM, Martell-Chavez F, Pineda-Arellano CA (2020) Control algorithms applied to active solar tracking systems: a review. Sol Energy 212:203–219

Maish AB (1990) Performance of a self-aligning solar array tracking controller (No. SAND-89–2571C; CONF-900542–2). Sandia National Labs., Albuquerque, NM (USA)

Brown DG, Stone KW (1993) High accuracy/low cost tracking system for solar concentrators using a neural network. SAE, WARRENDALE, PA (USA), 2, pp 577–584

Yousef HA (1999) Design and implementation of a fuzzy logic computer- controlled sun tracking system. In: ISIE'99 proceedings of the IEEE international symposium on industrial electronics (Cat. No. 99TH8465), vol 3. IEEE, pp 1030–1034

Zhang J, Yin Z, Jin P (2019) Error analysis and auto correction of hybrid solar tracking system using photo sensors and orientation algorithm. Energy 182:585–593

Safan YM, Shaaban S, El-Sebah MIA (2017) Hybrid control of a solar tracking system using SUI-PID controller. In: 2017 Sensors networks smart and emerging technologies (SENSET). IEEE, pp 1–4

Yeh HY, Lee CD (2012) The logic-based supervisor control for sun-tracking system of 1 MW HCPV demo plant: study case. Appl Sci 2(1):100–113

Kiyak E, Gol G (2016) A comparison of fuzzy logic and PID controller for a single-axis solar tracking system. Renew Wind Water Solar 3(1):1–14

Huang CH, Pan HY, Lin KC (2016) Development of intelligent fuzzy controller for a two-axis solar tracking system. Appl Sci 6(5):130

Robles Algarín C, Sevilla Hernández D, Restrepo Leal D (2018) A low-cost maximum power point tracking system based on neural network inverse model controller. Electronics 7(1):4

Arif EMH, Hossen J, Ramana G, Bhuvaneswari T, Velrajkumar P, Venkataseshaiah C (2018) A survey on neuro-fuzzy controllers for solar panel tracking systems. Far East J Electron Commun 18(7):981–1003

Aldair AA, Obed AA, Halihal AF (2016) Design and implementation of neuro- fuzzy controller using FPGA for sun tracking system. Iraqi J Electr Electron Eng 12(2)

Mashohor S, Samsudin K, Noor AM, Rahman ARA (2008) Evaluation of genetic algorithm based solar tracking system for photovoltaic panels. In: 2008 IEEE international conference on sustainable energy technologies. IEEE, pp 269–273

Mohanta JC, Keshari A (2019) A knowledge based fuzzy-probabilistic roadmap method for mobile robot navigation. App Soft Comput 79:391–409, ISSN 1568–4946, https://doi.org/10.1016/j.asoc.2019.03.055

Sanyal A, Nayab Zafar M, Mohanta JC, Faiyaz Ahmed M (2021) Path planning approaches for mobile robot navigation in various environments: a review. In: Kumar N, Tibor S, Sindhwani R, Lee J, Srivastava P (eds) Advances in interdisciplinary engineering. lecture notes in mechanical engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-9956-9_55

Bosi M, Pelosi C (2007) The potential of III-V semiconductors as terrestrial photovoltaic devices. Prog Photovoltaics Res Appl 15(1):51–68

Solanki CS, Beaucarne G (2007) Advanced solar cell concepts. Energy Sustain Dev 11(3):17–23

Toivola M, Halme J, Miettunen K, Aitola K, Lund PD (2009) Nanostructured dye solar cells on flexible substrates. Int J Energy Res 33(13):1145–1160

Hillhouse HW, Beard MC (2009) Solar cells from colloidal nanocrystals: fundamentals, materials, devices, and economics. Curr Opin Colloid Interface Sci 14(4):245–259

Hoppe H, Sariciftci NS (2004) Organic solar cells: an overview. J Mater Res 19(7):1924–1945

Khaselev O, Turner JA (1998) A monolithic photovoltaic-photoelectrochemical device for hydrogen production via water splitting. Science 280(5362):425–427

Goswami DY, Vijayaraghavan S, Lu S, Tamm G (2004) New and emerging developments in solar energy. Sol Energy 76(1–3):33–43

Miles RW, Zoppi G, Forbes I (2007) Inorganic photovoltaic cells. Mater Today 10(11):20–27

Günes S, Sariciftci NS (2008) Hybrid solar cells. Inorganica Chimica Acta 361(3):581–588. Goetzberger A, Hebling C, Schock HW (2003) Photovoltaic materials, history, status and outlook. Mater Sci Eng R: Reports 40(1):1–46

Guha S, Yang J (2006) Progress in amorphous and nanocrystalline silicon solar cells. J Non-Cryst Solids 352(9–20):1917–1921

Sidek MHM, Azis N, Hasan WZW, Ab Kadir MZA, Shafie S, Radzi MAM (2017) Automated positioning dual-axis solar tracking system with precision elevation and azimuth angle control. Energy 124:160–170

Pachauri RK, Mahela OP, Khan B, Kumar A, Agarwal S, Alhelou HH, Bai J (2021) Development of arduino assisted data acquisition system for solar photovoltaic array characterization under partial shading conditions. Comput Electr Eng 92:107175

Ahmed MF, Mohanta JC, Zafar MN (2022) Development of smart quadcopter for autonomous overhead power transmission line inspections. Mater Today Proc 51(1):261–268, ISSN 2214–7853, https://doi.org/10.1016/j.matpr.2021.05.271

Ahmed MF, Zafar MN, Mohanta JC (2020) Modeling and analysis of quadcopter F450 frame. In: 2020 international conference on contemporary computing and applications (IC3A), pp 196–201. https://doi.org/10.1109/IC3A48958.2020.233296

Khan RA, Mahmood MR, Haque A (2018) Enhanced energy extraction in an open loop single-axis solar tracking PV system with optimized tracker rotation about tilted axis. J Renew Sustain Energy 10(4):045301

Mollahasanoglu M, Okumus Hİ (2021) Performance evaluation of the designed two-axis solar tracking system for Trabzon. IETE J Res 1–13

Makhija S, Khatwani A, Khan MF, Goel V, Roja MM. Design and implementation of an automated dual-axis solar tracker with data-logging. In: 2017 international conference on inventive systems and control (ICISC). IEEE, pp 1–4

Okandeji AA, Olajide MB, Olasunkanmi GO, Jagun ZO (2020) Analysis and implementation of a solar tracking rack system. Niger J Technol 39(3):871–886

Zakariah A, Jamian JJ, Yunus MAM (2015) Dual-axis solar tracking system based on fuzzy logic control and light dependent resistors as feedback path elements. In: 2015 IEEE student conference on research and development (SCOReD). IEEE, pp 139–144

Azizi K, Ghaffari A (2013) Design and manufacturing of a high-precision sun tracking system based on image processing. Int J Photoenergy

Download references

Author information

Authors and affiliations.

Department of Mechanical Engineering, MNNIT Allahabad, Prayagraj, 211004, India

Alok Sanyal, MD Faiyaz Ahmed & J. C. Mohanta

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Alok Sanyal .

Editor information

Editors and affiliations.

Department of Mechanical and Mechatronics Engineering, University of Waterloo, Waterloo, ON, Canada

Institute of Fundamental and Frontier Sciences, University of Electronic Science and Technology of China, Chengdu, Sichuan, China

Mohammad Mehdi Rashidi

Department of Mechanical Engineering, The NorthCap University, Gurugram, Haryana, India

Rohit Singh Lather

Department of Mechanical Engineering, The NorthCap University, Gurugram, India

Roshan Raman

Rights and permissions

Reprints and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter.

Sanyal, A., Ahmed, M.F., Mohanta, J.C. (2023). Recent Developments and Challenges in Solar Harvesting of Photovoltaic System: A Review. In: Li, X., Rashidi, M.M., Lather, R.S., Raman, R. (eds) Emerging Trends in Mechanical and Industrial Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-6945-4_18

Download citation

DOI : https://doi.org/10.1007/978-981-19-6945-4_18

Published : 01 January 2023

Publisher Name : Springer, Singapore

Print ISBN : 978-981-19-6944-7

Online ISBN : 978-981-19-6945-4

eBook Packages : Engineering Engineering (R0)

Share this chapter

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Publish with us

Policies and ethics

- Find a journal

- Track your research

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Materials (Basel)

Photovoltaic Cell Generations and Current Research Directions for Their Development

Associated data.

Not applicable.

The purpose of this paper is to discuss the different generations of photovoltaic cells and current research directions focusing on their development and manufacturing technologies. The introduction describes the importance of photovoltaics in the context of environmental protection, as well as the elimination of fossil sources. It then focuses on presenting the known generations of photovoltaic cells to date, mainly in terms of the achievable solar-to-electric conversion efficiencies, as well as the technology for their manufacture. In particular, the third generation of photovoltaic cells and recent trends in its field, including multi-junction cells and cells with intermediate energy levels in the forbidden band of silicon, are discussed. We also present the latest developments in photovoltaic cell manufacturing technology, using the fourth-generation graphene-based photovoltaic cells as an example. An extensive review of the world literature led us to the conclusion that, despite the appearance of newer types of photovoltaic cells, silicon cells still have the largest market share, and research into ways to improve their efficiency is still relevant.

1. Introduction

Concerns about climate change and the increase in demand for electricity due to, among other things, an ever-growing population, necessitate efforts to move away from conventional methods of energy production. Rising carbon dioxide levels in the atmosphere caused by the use of fossil fuels is one of the factors causing ongoing climate change. Switching to renewable energy will produce energy with a smaller environmental footprint compared to fossil fuel sources. We are able to harness the full potential of sunlight energy to develop the best possible energy harvesting technologies capable of converting solar energy into electricity [ 1 ].

The currently used solar energy is very marginal—0.015% is used for electricity production, 0.3% for heating, and 11% is used in the natural photosynthesis of biomass. In contrast, about 80–85% of global energy needs are met by fossil fuels. The difficulty with fossil fuels is that their resources are limited and hostile to the environment due to their CO 2 emissions. For instance, for every ton of coal burned, one ton of carbon dioxide is released into the atmosphere. This emitted carbon dioxide is toxic to the environment and is a primary cause of global warming, the greenhouse effect, climate change, and ozone depletion [ 2 ].

The necessity of finding new renewable energy forms is extremely relevant and urgent today. That is why mankind must find alternative sources of energy to provide a clean and sustainable future. Within this context, solar energy is the best option among all alternative renewable energy sources due to its widespread accessibility, universality, and eco-friendly nature [ 3 ].

The most common metric used to evaluate the performance of photovoltaic technologies is conversion efficiency, which expresses the ratio of solar energy input to electrical energy output. The efficiency combines multiple component characteristics of the system, such as short-circuit current, open-circuit voltage, and fill factor, which in turn are dependent upon basic material features and manufacturing defects [ 4 ].

The cost-effectiveness of making a photovoltaic cell and its efficiency depend on the material from which it is made. Much research in this field has been carried out to find the material that is the most efficient and cost-effective for building photovoltaic cells. The specifications for an ideal material for PV solar cells include the following [ 5 ]:

- The cells are expected to have a band gap between 1.1 and 1.7 eV;

- Should have a direct band structure;

- Need to be easily accessible and non-toxic; and

- Should have high photovoltaic conversion efficiency [ 5 ].

A key problem in the area of photovoltaic cell development is the development of methods to achieve the highest possible efficiency at the lowest possible production cost. Improving the efficiency of solar cells is possible by using effective ways to reduce the internal losses of the cell. There are three basic types of losses: optical, quantum, and electrical, which have different sources of origin. Reducing losses of any kind requires different, often advanced, methods of cell manufacturing and photovoltaic module production. An upper efficiency limit for commercially accessible technologies is determined by the well-known Shockley–Queisser (SQ) limit, taking into account the balance between photogeneration and radiative recombination [ 6 ].

However, the greatest potential lies in the ability to reduce quantum losses, as they are intimately connected with the material properties and internal structure of the cell. Relevant here is the concept of band gap, which defines the minimum required energy of a photon incident onto the cell surface for it to take part in the photovoltaic conversion process. There is a relationship between the efficiency of the cell and the value of the band gap, which in turn is highly dependent on the material from which the photovoltaic cell is made. The basic, commonly used material for solar cells is silicon, which has a band gap value of about 1.12 eV, but by introducing modifications in its crystal structure, the physical properties of the material, especially the band gap width, can be affected [ 7 ].

The dominant loss mechanisms in conventional photovoltaic cells are the inability to absorb photons below the band gap and the thermalization of solar photons with energies above the band gap energy. Third-generation solar cell concepts have been proposed to address these two loss mechanisms in an attempt to improve solar cell performance. These solutions aim to exploit the entire spectrum by incorporating novel mechanisms to create new electron–hole pairs [ 8 ].

Major development potential among these concepts for improving the power generation efficiency of solar cells made of silicon is shown by the idea of cells whose basic feature is an additional intermediate band in the band gap model of silicon. It is located between the conduction band and the valence band, and its function is to allow the absorption of photons with energies below the width of the energy gap, resulting in higher quantum efficiency (a higher number of excited electrons in relation to the number of photons incident onto the surface of the cell) [ 9 ]. Currently, many directions of research development on the introduction of intermediate bands in semiconductors can be identified. One of them is the use of ion implantation, where two methods can be distinguished: introduction of dopants with extremely high concentrations to the substrate of the semiconductor, and implantation of the layer of silicon with high-dose metal ions [ 10 ].

The improvement of solar cell efficiency involves reducing various types of losses affecting the resultant cell efficiency. The National Renewable Energy Laboratory (NREL) runs a compilation of the highest verified research cell conversion efficiencies for different photovoltaic technologies, compiled from 1976 to the present ( Figure 1 ). Cell efficiency results are given for each semiconductor family: multi-junction cells; gallium arsenide single-junction cells; crystalline silicon cells; thin film technologies; emerging photovoltaic technologies. The latest world record for an individual technology is indicated by a flag across the right edge containing the efficiency and technology symbol [ 11 ].

NREL Best Research-Cell Efficiencies chart [ 11 ].

Photovoltaic cells can be categorized by four main generations: first, second, third, and fourth generation. The details of each are discussed in the next section.

2. Photovoltaic Cell Generations

In the past decade, photovoltaics have become a major contributor to the ongoing energy transition. Advances relating to materials and manufacturing methods have had a significant role behind that development. However, there are still numerous challenges before photovoltaics can provide cleaner and low-cost energy. Research in this direction is focused on efficient photovoltaic devices such as multi-junction cells, graphene or intermediate band gap cells, and printable solar cell materials such as quantum dots [ 12 ].

The primary role of a photovoltaic cell is to receive solar radiation as pure light and transform it into electrical energy in a conversion process called the photovoltaic effect. There are several technologies involved with the manufacturing process of photovoltaic cells, using material modification with different photoelectric conversion efficiencies in the cell components. Due to the emergence of many non-conventional manufacturing methods for fabricating functioning solar cells, photovoltaic technologies can be divided into four major generations, which is shown in Figure 2 [ 13 ].

Various solar cell types and current developments within this field [ 14 ].

The generations of various photovoltaic cells essentially tell the story of the stages of their past evolution. There are four main categories that are described as the generations of photovoltaic technology for the last few decades, since the invention of solar cells [ 15 ]:

- First Generation: This category includes photovoltaic cell technologies based on monocrystalline and polycrystalline silicon and gallium arsenide (GaAs).