Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

CASE STUDY I: KOYNA HYDROELECTRIC POWER PLANT (KHPP

Introduction:

Related Papers

kavin robert

Waqar Moazzam

Omolafe Samuel

Prateek jena

Enrico Bocci

Rizani Rusli

Rajib Maharjan

Alie Dametew

Hydropower, large and small, remains by far the most important of the " renewable " for electrical power production worldwide. Small-scale hydro is in most cases " run-of-river " , with no dam, and is one of the most cost-effective and environmentally benign energy technologies to be considered both for rural electrification in less developed countries and developed countries for further hydro developments countries(like Ethiopia). This paper addresses power generation for rural applications by means of small hydropower plants by using cross-flow turbine systems .The cross-flow turbine is suitable for installing small hydroelectric power plants in case of low head and flow rate. Using mathematical analysis a complete design of such turbines has been done in this paper. Abstract-Hydropower, large and small, remains by far the most important of the " renewable " for electrical power production worldwide. Small-scale hydro is in most cases " run-of-river " , with no dam, and is one of the most cost-effective and environmentally benign energy technologies to be considered both for rural electrification in less developed countries and developed countries for further hydro developments countries(like Ethiopia). This paper addresses power generation for rural applications by means of small hydropower plants by using cross-flow turbine systems .The cross-flow turbine is suitable for installing small hydroelectric power plants in case of low head and flow rate. Using mathematical analysis a complete design of such turbines has been done in this paper. The complete design parameters such as, Turbine material, runner diameter, runner length, water jet thickness, blade spacing, radius of blade curvature, turbine power, turbine speed, number of blades, and any losses in the pipe due to friction, were determined at maximum turbine efficiency. Small Hydro turbine System Design Operation procedure, Recommendations and possible economic impact for small hydropower generation are also highlighted.

RELATED PAPERS

IAEME Publication

Umer Farooq

REVIEW AND TECHNICAL STUDY OF HYDROELECTRIC POWER GENERATION

Dr. Osama M Elmardi

Dr. KADIRI, Kamoru Oluwatoyin FNSE, FNIEEE, FIDPM

sumit thakur

gajanan dhanegaokar

prime patel

Mohamed Mashooth

Ajirenike tEe

Sardar Taimur Hyat-Khan

Hydroelectric Power Generation Dr. Osama Mohammed Elmardi Suleiman Khayal

Renewable & Sustainable Energy Reviews

hashim hizam

Sawsan Ahmed Elhouri

Cédric PHILIBERT

Nadeem Uddin

djoko susijono

The Ijes The Ijes

mennatallah elshamiii

Abdallah Abdelaziz

ABDALLAH ABDELAZIZ

Girish Bhiogade

Renewable and Sustainable Energy Reviews

Shafiqur Rehman

Mark Z. Jacobson

Christopher Koroneos

Vinod Yadav

Wikash Ramnares

Dr. Amartya Kumar Bhattacharya

Mahmood Abdullrahman

KAUSHALPRASAD CHAUHAN

Vikrant Kumar

Rasel A Sultan , Md. Shad Rahman

Joep Vonk , Nienke Stam

Gregor Wolbring

Sidhartha Mangaraj

ijcsitce journal

Matthew Leach

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

International Journal of Engineering and Technical Research (IJETR) ISSN: 2321-0869, Volume-3, Issue-5, May 2015 Dam Instrumentation in Gravity Dams : A Case Study on Koyna Dam

Mr. A. R. Chavan, Dr. S. S. Valunjkar

Abstract - Number of aspects, parameters is assumed while total movements between zones of an embankment and its designing the dams. The materials are tested in laboratories foundation may also need to be monitored. For a given and designs are based on assumptions that the same results will project to ensure all critical conditions, a wide variety of be met with, during actual construction in most of the cases. instruments may be applied in a comprehensive monitoring The actual product defers from the original assumptions as program are covered sufficiently. there are always large deviations in materials, their properties, construction methods and their control. How the actual For verification of design assumptions, construction constructed dam acts against the expectations made that must technique & modification design, Instrumentation in dam is be known by engineer. In this paper, the requirement, use and necessary. In determination of specific cause of failure, data operation of the instruments required to check the behaviour collected from instrument could be tremendously valuable. and stability of dams are discussed. These instruments show A constant watch over the performance of the structure their effectiveness in proper maintenance of dam, and hence during service is taken care by instrumentation and obtains they should be installed at appropriate places in the dam under timely notices in respect of distress spots. Safety in dam can the guidance of experts. It has been concluded from present be assist by instrumentation. Recent dam failures in various study that there should be close co-operation between the part of world inspire important interest in monitoring designers, instrumentation specialist, expert analysis and site authorities to achieve the goal of instrumentation. various parameters as a means for ensuring adequate margin of safety. Basic parameters like pore pressure, displacement, Index Terms—Dam; Instruments; Dam Safety; Précautions; seepage, strains, stresses, dynamic load, uplift pressure, Failure; Remedies; Assumptions etc. temperature can study as per IS specification with the help of instrumentation. I. INTRODUCTION In India there are about 4291 large dams. Out of these 1529 dams are in Maharashtra from which near about 40 It is essential for Engineers to design the dam to Dams are instrumented. The approximate cost of these withstand alongside any damage because it is said that, instruments is near about to 1% of total construction cost of “Dam instrumentation means number of instruments dams. embedded in the body of dam to accumulate basic factors & to check behaviour of dam”. II. PLANNING OF INSTRUMENTATION Number of factors, parameters is assumed while designing dams. The materials are tested in laboratories and A. Importance of the instrumentation designs are based on expectations that the same results will Instruments play an vital role in checking the safety of the be met with, during actual construction in most of the cases. dams as instruments embedded in or installed at the surface The actual product defers from the unusual assumptions as of the dam keep a constant watch over their service and there are always large deviations in materials, their indicate the distress spot which call for remedial measures. properties, construction methods and their control. This could be found out by many techniques. How the actual A cumulative record for structural behaviour of dams is formed from the observations of the instruments. In constructed dam behaves against the assumptions made that modifying theoretical assumptions and includes the effect of must be known by engineer. For filling structural behaviour, field observations, the study of structural behaviour provides essential help from various instruments implanted in a dam an important aid. body is taken. The operational of a structure or a system or the operation of a process depends on these instruments are TABLE I. Instruments used to obtain parameters devices to measure and / or control the variables. Generally the major objectives of a geotechnical Parameters Instruments instrumentation plan may divide into four categories: first, Surface 1. Tilt meter analytical assessment; second, prediction of future Displacement 2. Surface extensometer performance; third, legal evaluation; and fourth, 1. For Structures on permeable foundation development and verification of future designs. These Uplift Pressure instruments. objectives of instrumentation can be achieved by providing 2. Instruments for structures on rock foundations measureable data to assess groundwater pressure, Dynamic Loads 1. Seismometer 1. Total Pressure Cells deformation, total stress, temperature, seismic events, Stress leakage, and water levels. Relative movements as well as 2. Jack-Out Total Pressure

1.“v”notch weir large Discharge Seepage Mr. A. R. Chavan,PG Student, Department of Civil Engineering, Govt. 1.Open stand pipe piezometer College of Engineering Karad , Satara 415124, Karad, Maharashtra, India. Pore Water 7798482976. 2.Pneumatic piezometer Pressure

3.Vibrating wire piezometer Dr. S. S. Valunjkar, Professor and Head of Civil Engineering Department, Govt. College of Engineering Karad, Dist: To provide for unknowns in the designs, most hydraulic Satara.415124,Karad, Maharashtra, India.9422701525. structures are built on rather conservative assumptions.

40 www.erpublication.org Dam Instrumentation in Gravity Dams: A Case Study on Koyna Dam

Observations from the instruments help to reduce these making a selection of instruments for earth dam are unknowns and place future designs on sounder footing. discussed in the following paragraphs. The instrumentation data also helps in the process of research and developments and also advancing the state of 1. Conformance art. The present age instrumentation has become necessity to Ideally, the presence of a measuring instrument should insure proper functioning, safety as well as the optimum not alter the value of the parameter being measured. If in utilization of resources. fact the instrument alters the value, it is said to have poor Following table shows the instruments used to obtain conformance. For example, Earth pressure cells should parameter: ideally have the same deformability characteristics as the material in which they are placed. In addition the act of B. Failure of Dam compacting fills around an instrument should not result in a significantly different condition within the soil mass. The incidents of failures demonstrate that failure of dams Similarly piezometers should not create drainage paths that depends on the type of the dam. Various types of dam would reduce the measured pore water pressure below the failure are listed below: value elsewhere. Conformance is a desirable ingredient of 1. Sliding of dam high accuracy. 2. Overturning of dam 3. Tension failure of dam 2. Accuracy 4. Crushing of dam Accuracy is the closeness of approach of a measurement to the time value of Quantity measured. Absolute accuracy is not only difficult to attain but also TABLE II. Causes of dam failure in percentage difficult to define and demonstrate. Accuracy of an Sr.No Cause Percentage failure instrument is evaluated during calibration. The true value is 1 Foundation failure 40 % the value indicated by an instrument whose accuracy is verified and traceable to an accepted standard. Wherever 2 Inadequate spillway 23% possible traceable value should be with respect to the Indian 3 Poor construction 12% Bureau of Standard. The accuracy of instrument depends on 4 Uneven settlement 10% accuracy of each component of that instrument. The degree 5 High pore pressure 05% of instrument accuracy need only be as high as the ability to 6 Acts of war 03% define the anisotropy of the parameters. 7 Embankment slips 02% 3. Repeatability 8 Defective materials 02% Repeatability (Precision or Reliability) is the measures 9 Incorrect operation 02% of the smallest reading which can be consistently 10 Earthquakes 01% reproduced provided that the parameter being measured has not changed. The difference between accuracy and precision III. SYSTEM DEVELOPMENT is illustrated in fig. 3.1. The bull's eye in the figure The following parameters need to be measured as per IS represents the true value. In the first case, the measurements specifications: are precise but not accurate, as would occur when using a 1) Pore pressure survey tape with a bad kink. Such errors are systematic. In 2) Displacement the second case the measurements lack precision but if 3) Seepage sufficient readings are taken, the average will be accurate. 4) Strains Such errors are random. In third, the measurements are both 5) Stresses precise and accurate. 6) Dynamic loads 7) Uplift pressure 4. Range 8) Temperature The need of adequate measuring range is sometimes overlooked because stress or shape change magnitudes of A. Characteristics of Good Instruments parameters, particularly in geological masses are difficult to The state of instrumentation design is far ahead of the predict. Range should be adequate, but not excessive, as art in user technology. The various instruments commonly range can generally be obtained only at the expense of some available for measuring various parameters have been other desirable characteristics usually resolution. discussed in chapter 2 of this dissertation. Less than 2 decades ago the instruments deployed were simple and it 5. Survivability was possible for the Civil Engineer to have a good Instruments must be capable of surviving for the knowledge of the operating principles and characteristics of duration of the prospective measurement. Cables, tubes or such instruments. Since that time there have been major pipes' that connect the, transducer to its readout unit must be advances in the development of new instruments. The able to survive imposed pressure changes, deformation, design of new generation instruments has gone into the water, sunlight and chemical effects such as corrosion and domain of the instrument, engineer rather than the Civil electrolytic breakdown. This is not always a simple Engineer. It is the responsibility of the user to develop an requirement as surrounding conditions of instruments are adequate level of understanding of the instruments before frequently more severe than anticipated. they select a particular instrument. Some general 6. Hysteresis fundamental characteristics that are to be considered while

41 www.erpublication.org

International Journal of Engineering and Technical Research (IJETR) ISSN: 2321-0869, Volume-3, Issue-5, May 2015 When the quantity being measured is subjected to cyclic B. Introduction change, the indicated measured value sometimes depends on Koyna Dam is a rubble concrete dam 103.02 m high whether the measurement is increasing or decreasing. If the above the deepest foundation level, and 85.35 m high above two relationships are plotted the separation between the two River Bed. It has a total length of 807.22 m. It is constructed curves is a measure of hysteresis. Instruments with large across river Koyna, which is a major a tributary of River hysteresis are not suitable for measurement of rapidly Krishna. The dam is located near village Deshmukhwadi in changing parameters. Patan Tahasil in Satara district of Maharashtra State of India. The Dam is founded on basalt rock. Koyna is one of 7. Noise the major Hydro Electric Projects in the Country. The dam Noise is a term used to cover random measurement impounds 2980.34 MCum water to generate 1960 MW variation caused by external factors, creating lack of power. precision and accuracy. Excessive noise in a system may The dam is built in 53 monoliths of which six end mask small real changes. Groundwater interference in monoliths are constructed in masonry and the rest in rubble leakage were due to rain is an example of external factor concrete. The spillway is centrally located and extends from that creates noise and affect the measurement of the seepage monolith number 18 to 24 over a length of 88.70 m. six through embankment. radial gates of size 41 ft X 25 ft are installed in the spillway (manufacturers M/s Conrad Czoke). In year 2003, these 8. Cost gates are fixed with 5 ft high flaps which are independently Comparison of cost should only be undertaken amongst operated hydraulically. The height of gates can thus now be those instruments which meet all the specifications considered as 30 ft. Catchment area of the Dam is 891.78 discussed above. Any attempt to save expenditure by SqKm and submerged area is 115.35 SqKm. 98 villages relaxing specifications often result in waste of funds since were affected by the submergence and 9069 families were such relaxation results in instrument not performing the task displaced. These families are rehabilitated in 6 districts viz it is chosen for practically it is impossible to select the Satara, Sangali, Solapur, Kolhapur, Raigad and Ratnagiri. instrument which conforms all above capabilities. The topography near the initial regime of Koyna River Therefore, engineer has to make some compromise for is very favorable for the location of Hydro Electric Project. selection of particular instruments. In order to satisfy one There is a sheer vertical drop of 487.68 meters (1600 feet) factor he may have to sacrifice the other. This leads to the on west side of the reservoir. The continental divide is only errors in measurements. 56 Km. (35miles) from the Arabian Sea, and separates the land between the 579 meter (1900 feet) high ground of IV. CASE STUDY- KOYNA DAM Koyna on the Eastern Side of the Sahyadri Range and the To get more detailed knowledge about dam instruments 152 m (500 feet) high base on an escarpment on its Western and its components, a case study was conducted at KOYNA Side. This has rendered a high head Hydro Electric Scheme DAM. This section discusses the various aspects of the case feasible at economical cost. Since the rock through which study considering the perspective of dam instrumentation the tunnels pass is excellent basalt rock, it was possible to and its applications. take advantage of this rock by transmitting part pressure of A. General water to rock and part to steel plates which led to economy. Straight excavation of pressure shafts resulted in reduction Salient features of Koyna Dam: in the length and saving in cost of Steel plates and annular 1. Name of Dam: Koyna Dam concrete & thus enabled adoption of underground Power 2. Name of River: KOYNA RIVER House. Thus Koyna Stage I&II Power Station went 3. Location: Village: Deshmukhwadi, Tal. Patan Dist. Satara underground for the purpose of economy and safety. The 4. Catchments Area: A. Main Dam : 891.78 Sq.km. Project subsequently developed in four stages to reach B. Avg. Rainfall : 5350 mm power production capacity today totaling to 1960 MW. 5. Dam & Reservoir: Stage I & II accommodates 4 generators of 65 MW capacity A. Gross Storage: 2980.68 M CUM / 105.26 TMC and 4 generators of 75 MW capacity, totaling to 560 MW as B. Live Storage: 2684.51 M CUM / 94.80 TMC a base station with 60% load factor The tail water of stage I C. Dead Storage: 296.17M CUM / 10.46 TMC & II power house was initially released in Vashishthi River D. From Spillway crest to top of the gate: 908.18 M at KRL 133.20 m (433.00 feet). To utilize this unused CUM / 32.07 TMC residual head before the water goes to the Arabian Sea, the 6. Height of Dam: water was then diverted in adjoining Vaitarni Valley Above River bed: 85.35 m through a 4.5 Km long tunnel and was stored behind a dam, Above foundation: 103.02 m called Kolkewadi Dam , 497 m long and 56.80 m high, to 7. Length of Dam: generate 320 MW with four machines of 80 MW each in the Main Dam: 807.72 m Dam Foot Power House. This is called as Stage III, which Top of Dam: 654.97 m was designed as a peaking station with 24% load factor. 8. Spillway gates 6 Nos. Tainer type: 12.50 m X 7.62 m Water for Irrigation was being released eastwards through a 9. Design Purpose: Hydro Electric Project and Irrigation River Sluice in the main dam till 1980. To use the static Project. head of height of reservoir, a dam foot Power House was 10. Hydro Electric Power Generation: constructed on right flank of the Dam during 1975 to 1980. A. Main Dam : 1960 MW. 2 generators of 20 MW capacities are installed in this Power House, thereby generating 40 MW in Irrigation Rotation Period. Around 1985 it was realized that there is a vast diurnal hourly fluctuation in the power demand. Maximum

42 www.erpublication.org Dam Instrumentation in Gravity Dams: A Case Study on Koyna Dam power demand in morning peak (7 to 11 am) period and in 4. Joint meter evening peak (7 to 11 pm) period was as much as 15000 5. Uplift pressure cells. MW, while in between period it slowly reduces to 9000 All these instruments are embedded in M.No 17 it being the MW. It was concluded that hydro power stations need not be deepest monolith. All these instruments are embedded run at 60% power factor. They can be run only in peak hours during construction period 1969 to 1972. with 25% (or even less) Power factor. Then I&II stage PH was generating at 60% PF and utilizing 67.5 TMC of water. E. Frequency of Observation If the PF is reduced, westward water quota cannot be fully utilized. If a parallel Power House is built, and both the Once in a week in fair weather season. Power Houses are run with 25% PF, then the quota can be Twice in a week in rainy season. utilized fully. This concept gave rise to the IV stage Power After every sizable earthquake. House of Koyna Project. Accordingly a new Powerhouse 2. Earth pressure cells for observation of stresses in dam. comprising of 4 generators of 250 MW each was 3. Surface settlement plugs for measuring embankment constructed and commissioned in 1999/2000. movements. 4. Peak recording accelerographs to measure the ground acceleration duration earthquake. C. Necessity of Instrumentation 5. Seismoscope to determine displacement relative velocity The behaviour of this dam will have to be and acceleration response of dam to earthquake. monitored carefully particularly with reference to the following points: 1. Instruments embedded in or installed at the surface of F. Seismic Instruments the dam keep a constant watch over their service and The following types of instruments are installed in indicate the distress spot which call for remedial measures. various observatories: Thus instruments play an important role in checking the 1. Wood Anderson Seismometer safety of the dams. 2. Electromagnetic Seismometer 2. The Instrumentation data also helps in the process of 3. High Frequency Seismometer research and developments and also advancing the state of 4. Kirnos Seismometer art. 5. MEQ Seismographs 3. The dam is located in highly seismic zone, with this 6. Accelerograph point of view and even otherwise, the vertical settlement of a. A.R. 240 dam as well as its horizontal spread on u /s and d /s needs to b. RFT 250 be monitored. c. Roorkee 4. The behaviour of dam for comparison with design d. Peak Recording assumptions is to be observed. 5. The Koyna dam lies in heavy rainfall zone both in Koyna region lies in Zone IV of earthquake hazard quantum and intensity. It would be interesting to a certain as zoning. Below is a list of earthquakes having epicenter in or to how far does the heavy rainfall affect the saturation of d near the Koynanagar region in last few decades. /s slope even after provision of pitching. TABLE III. EARTHQUAKES RECORDED AT KOYNA DAM D. Types of Instruments Installed Richter Depth In order to monitor the safety, the dam was well Decades Occurrences instrumented since early construction stage. Following scale (Km) instruments have fixed in the dam for observation. Instruments Nos. Location/s Pre 67 5.4 2 4.9 1. Uplift pressure cells 66 M.No.1-C-1-G 21 24 25 and stilling basin 1967 6 3 11.6 2.Co-Ordimeters 2 M.No.22 and 25 3. Thermometers 52 M.No 22 1980s 4.3 3 22.3 4. Stress Meters 17 M.No 22 5. Strain meter 38 M.No 22 1990s 4.9 2 5.5 6. Dial Gauges 6 Cross gallery in M.No 21 2000s 4.7 8 10.7 7. Piezometers 4 Lift Bank Out off 8.Spillway 9 M.No 22 Spill Way. 2010s 4.9 1 11 Thermometers

Instrumentation in Koyna Dam Concrete Backing to G. Feedback to Central Water and Power Research Station study the Structural behaviour of Concrete Backing consists The data collected from the seismological observatories of following instrument; of the Koyna network is regularly analyzed by Central 1. Thermometer Water and Power Research Station, Pune . The data from all 2. Stress meter other instruments is sent to MERI for further analysis. 3. Strain meter

43 www.erpublication.org

International Journal of Engineering and Technical Research (IJETR) ISSN: 2321-0869, Volume-3, Issue-5, May 2015 FIGURE 1 ANALYSIS OF EARTH QUAKES ATKOYNA DAM

FIGURE 2 ACCELLEROGRAM RECORDED IN 1967

V. INSTRUMENTS INSTALLED AT KOYNA DAM 3.Analogue Seismograph

1.Tiltmeter

4.V-Notch Weir 2.Seismograph

44 www.erpublication.org Dam Instrumentation in Gravity Dams: A Case Study on Koyna Dam

5. Location of Thermometer, Stress meter, Strain Meter construction of dam was also crucial part. If the dam is in proper condition it means that the seepage and erosion in the body are at minimum level. In such cases where the condition of a dam is not vulnerable to future attack of various forces like seepage, pore pressure etc. It does not require large scaled instrumentation in body of dam and it could be managed at some primary level of instrumentation by providing some small sized instruments like strain gauge, stress gauge etc. But in the case of dam where the seepage is considerable and the material used in the dam is of pure quality, in such case dam instrumentation should be adopted and instruments like piezometer, foundation piezometer, embankment piezometer, Casagrande type porous tube piezometer, and terminal well should be used in order to ensure the safety of dam.

REFERENCES TABLE IV. DETAILS OF ACCELEROGRAPH STATIONS IN THE BODY

[1] Yanmaz Melih and Sezgin O. Ilke, “Evaluation Study on the Instrumentation System of Cindere Dam”, J. Perform. Constr. Facil. 2009.23:415-422. [2] Myers Barry K., P.E. Scofield David H., P.E., C.E.G, “Providing Improved Dam Safety Monitoring Using Existing Staff Resources: Fern Ridge Dam Case Study”, Library of Congress Control Number: 2008924523 ISBN 978-1-884575-42-6. [3] Myers Barry and Stateler Jay, “Why include instrumentation in dam monitoring programs”, USSD Committee on monitoring of dams and their foundations. ISBN978-1-884575-45-7. [4] Su Huaizhi; Hu Jiang; and Wen Zhiping, “Service Life Predicting of Dam Systems with Correlated Failure Modes”, Journal Of Performance Of Constructed Facilities © Asce / May/June 2013. [5] Kramer Chris and Lee Michael D., “Preparedness for Dam Failures in the San Francisco Bay Area”, Nat. Hazards Rev. 2004.5:18-28. [6] Bernstone, C., Westberg, M., and Jeppsson, J. (2009). “Structural assessment of a concrete dam based on uplift pressure monitoring.” J. Geotech. Geoenviron. Eng., 135(1), 133–142. [7] Bhadauria, S. S., and Gupta, M. C. (2006). “In-service durability performance of water tanks.” J. Perform. Constr. Facil., 20(2), 136– 145.

[8] Bowles, D. S. (2001). “Evaluation and use of risk estimates in dam safety decision making.” Proc., United Eng. Foundation Conf. on Risk-Based Decision-Making in Water Resources IX, ASCE, Reston, VI. CONCLUSION VA, 1–17. Different studies which have been done on dam [9] Chen, H. Q. (2009). “Lessons learned from Wenchuan earthquake for instrumentation are discussed in this paper, conclusions seismic safety of large dams.” Earthquake Eng. Eng. Vib., 8(2), 241– 249. obtained after studies are as follows: [10] Chen, J., and Huang, W. (2000). “Failure probability of gravity dam 1. There is different force which acts on body of dam. on rock foundation.” Int. Com. on Large Dams. The Ministry of But major forces which affects the stability of dam are uplift Water Resources, People’s Republic of China, Beijing, 425–436. pressure, dynamic loads etc. These kind of major forces [11] China Electric Council. (2000). “Unified design standard for reliability of hydraulic engineering structures in China.” The cannot be handled with traditional approach of dam standards compilation of water power in China, China Electric construction and hence it demand for dam instrumentation Council, Beijing. for better and ensured stability of dam. 2. While going through stress analysis of dam due to various forces, it has been observed that one set of instrument could not be used in every body of dam. It depends on various factors. 3. After selecting proper instrument, selecting the proper location of instrument is another vital part of dam instrumentation. But the location can be found out by many aspects need to be taken into account. Select the proper location of instrument in dam; this will lead to better performance of instrumentation in dam. 4. The data collected from Koyna dam, gives the idea about different forces acting, location of instrument to be used, type of instrument to be used etc. The major forces acting on the body of dam are observed as uplift force, seepage force, dynamic load etc. 5. For the stability and safety of dam, not only the part of instrumentation in dam is important but the part of

45 www.erpublication.org

This site uses cookies to optimize functionality and give you the best possible experience. If you continue to navigate this website beyond this page, cookies will be placed on your browser. To learn more about cookies, click here .

Switch language:

Data Insights

Power plant profile: koyna, india.

- Share on Linkedin

- Share on Facebook

Koyna is a 1,920MW hydro power project. It is located on Koyna river/basin in Maharashtra, India. According to GlobalData, who tracks and profiles over 170,000 power plants worldwide, the project is currently active. It has been developed in multiple phases. Post completion of construction, the project got commissioned in 1962. Buy the profile here.

Smarter leaders trust GlobalData

Premium insights koyna.

Buy the Profile

Premium Insights

The gold standard of business intelligence.

Find out more

Related Company Profiles

Bharat heavy electricals ltd, voith hydro holding gmbh & co kg.

Description The project is currently owned by Maharashtra State Power Generation with a stake of 100%. Koyna is a reservoir based project. The project generated 3,585.67 GWh of electricity. The Koyna (Koyna III) has 4 electric generators installed at the site.

Development status The project got commissioned in 1962.

Contractors involved Koyna (Koyna I) is equipped with GE Renewable Energy pelton turbines. The phase consists of 4 turbines with 76.8MW nameplate capacity. Koyna (Koyna II) is equipped with GE Renewable Energy pelton turbines. The phase consists of 4 turbines. Koyna (Koyna III) is equipped with Bharat Heavy Electricals francis turbines. The phase consists of 4 turbines with 80MW nameplate capacity. Koyna (Koyna IV) is equipped with GE Renewable Energy francis turbines. The phase consists of 4 turbines with 250MW nameplate capacity. Voith Hydro Holding supplied 4 electric generators for the Koyna (Koyna I). Voith Hydro Holding supplied 4 electric generators for the Koyna (Koyna II). GE Renewable Energy supplied electric generator(s) for the Koyna (Koyna IV).

For more details on Koyna, buy the profile here.

This content was updated on 4 January 2024

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.

Be better informed

GlobalData , the leading provider of industry intelligence, provided the underlying research used to produce this article.

This information is drawn from GlobalData’s Power Intelligence Center , which provides detailed profiles of over 170,000 active, planned and under construction power plants worldwide from announcement through to operation across all technologies and countries worldwide.

Data Insights Koyna

More relevant.

Study reveals best locations for wind power

Acwa power to invest in 200mw wind farm in uzbekistan, new fortress energy begins to build 1.6gw power plant in brazil, industrial power monitoring systems: condition, performance and diagnostics, sign up for our daily news round-up.

Give your business an edge with our leading industry insights.

Sign up to the newsletter: In Brief

Your corporate email address, i would also like to subscribe to:.

Future Power Technology : Focus (monthly)

Thematic Take (monthly)

I consent to Verdict Media Limited collecting my details provided via this form in accordance with Privacy Policy

Thank you for subscribing

View all newsletters from across the GlobalData Media network.

Koyna Stage IV Hydroelectric Project

Please provide your contact information:.

Our team will reach out to you in some time

The Koyna Hydroelectric Plant, a branch of the Krishna Basin, is a concrete dam 103.2 m above the foundation, built on the Koyna River, in Satara district, Maharashtra state, India. It is the second-largest hydroelectric project in the country and impounds water to generate 1960 MW in four phases. The power plant was established in the year 1966 with the first two phases; Due to the increase in demand, the power plant was expanded with a new stage with a capacity of 1000 MW, called "Stage-IV". The installed capacity of this stage alone is 1000 Mw. This stage is mostly used to cater for the peak hour demands of the electric grid.

The power plant uses water coming from the Koyna River for phases I, II, and IV. In Phase-IV, water is drawn directly from the reservoir in the Head Race Tunnel of length 4230 m and delivered to the Head Surge Tank.

Encardio-rite was awarded the sub-contract for supply as well as installation of safety monitoring instrumentation for the project in 2010. The instrumentation included:

- Piezometers

- Pressure cells

- Strain meters

- Borehole extensometer - multipoint

- Prism targets

- Total station

- Portable readout units and datalogger

Reference Projects

Indira Sagar Dam

Madhya Pradesh, India

Manipur, India

Maharashtra, India

Direct To Your Inbox !

Subscribe to our monthly newsletter and get access to the latest industry trends, insights & updates.

Already Subscribed your mail.

Thank you for subscribing to our newsletter.

- IAS Preparation

- UPSC Preparation Strategy

Koyna Dam: Notes for UPSC

Major dams and reservoirs in India are important for the UPSC civil services exam. It is a part of the Geography/environment and ecology sections of the IAS exam. In this article, you can read about the Koyna Dam, which is one of the largest dams in the state of Maharashtra.

What is the Koyna Dam?

The Koyna Dam is one of the largest dams in Maharashtra, India. It is a rubble-concrete dam constructed on Koyna River which rises in Mahabaleshwar, a hill station in Sahyadri ranges. It is located in Koyna Nagar, Satara district, nestled in the Western Ghats on the state highway between Chiplun and Karad.

What is the purpose behind its construction?

The main purpose of the dam is hydroelectricity with some irrigation in neighbouring areas. Today the Koyna Hydroelectric Project is the largest completed hydroelectric power plant in India having a total installed capacity of 1,920 MW. Due to its electricity generating potential Koyna river is considered as the ‘lifeline of Maharashtra’.

The spillway of the dam is located at the center. It has 6 radial gates. The dam plays a vital role in flood control in the monsoon season. The catchment area dams the Koyna river and forms the Shivsagar Lake which is approximately 50 km (31 mi) in length. It is one of the largest civil engineering projects commissioned after Indian independence. The Koya hydro-electric project is run by the Maharashtra State Electricity Board.

Koyna Dam:- Download PDF Here

Brief Details about the Koyna Dam

- Constructed on the Koyna River.

- Situated in Koyna Nagar in Satara District, Maharashtra.

- The dam is nestled in the Western Ghats.

- The chief purpose of the dam is to generate hydroelectricity and also a little bit of irrigation in the neighbouring areas.

- It is the largest completed hydroelectric power plant in India.

- It has a total installed capacity of 1,920 MW.

- In the 1967 earthquake at Koyna Nagar, the dam developed a few cracks. The dam has witnessed many other smaller earthquakes as well.

Get more NCERT Geography Notes for UPSC exam, by clicking on the linked article

Facts about the Koyna River

- The Koyna is a tributary of the river Krishna.

- It originates in Mahabaleshwar and meets the Krishna in a place called Karad, Satara.

- The confluence of the rivers Koyna and Krishna is called Preeti Sangam, meaning ‘confluence of love’.

- Karad is well-known for the production of sugar.

- The river flows in the north-south direction. Most other rivers flow in the east-west direction.

- The river is also called the ‘lifeline of Maharashtra’.

For more UPSC related preparation materials and articles, visit the links given in the table below

Related Links

Leave a Comment Cancel reply

Your Mobile number and Email id will not be published. Required fields are marked *

Request OTP on Voice Call

Post My Comment

IAS 2024 - Your dream can come true!

Download the ultimate guide to upsc cse preparation.

- Share Share

Register with BYJU'S & Download Free PDFs

Register with byju's & watch live videos.

- Rossby Waves

- 1. India: General Introduction

- COP26- Glasgow Conference

- The Global Stocktake

- The Advent of the Dutch in India

Recently, the Comptroller and Auditor General (CAG) of India informed about the delay in the grant of Revised Administrative Approval to an incomplete hydroelectric project in Maharashtra . The delay resulted in the funds being blocked for more than six years.

About Koyna Dam:

- The Koyna dam is one of the largest dams in Maharashtra, India.

- It is a rubble-concrete dam constructed on the Koyna River that originates in Mahabaleshwar, a hill station in the Sahyadri ranges. It is located in Koynanagar, Satara district, in the Western ghats on the state highway between Chiplun and Karad.

- The construction of the dam began in 1956 and it was opened in 1964.

- It is the 2nd largest completed hydroelectric project in India.

- After the first world war, a hydroelectric project on the Koyna river was built by the Tata group.

- This dam has experienced various tremors in the past due to which some cracks had appeared on it but later on it has been strengthened and it is believed to be strong enough to tolerate any tectonic activities in the future.

What is the purpose behind its construction?

The main purpose of the dam is hydroelectricity with some irrigation in neighbouring areas. Today the Koyna Hydroelectric Project is the largest completed hydroelectric power plant in India having a total installed capacity of 1,920 MW. Due to its electricity generating potential Koyna river is considered as the ‘lifeline of Maharashtra’.

The spillway of the dam is located at the center. It has 6 radial gates. The dam plays a vital role in flood control in the monsoon season. The catchment area dams the Koyna river and forms the Shivsagar Lake which is approximately 50 km (31 mi) in length. It is one of the largest civil engineering projects commissioned after Indian independence. The Koya hydro-electric project is run by the Maharashtra State Electricity Board.

Key Facts about the Koyna River

- The Koyna River is a tributary of the Krishna River which originates in Mahabaleshwar, Satara district, Western Maharashtra.

- Unlike most of the other rivers in Maharashtra which flow East-West direction, the Koyna River flows in North-South direction.

- With an elevation range of 550 – 1,460 m above mean sea level it typically represents a physiographic setup characterized by the Deccan plateau in the Western Ghats region.

- It is dammed by the Koyna Dam at Koynanagar forming the Shivsagar reservoir.

- Koyna River is supported by four tributaries. They are Kera, Wang, Morna and Mahind. Among these rivers Kera, Wang and Morna are dammed.

Krishna River System

- The Krishna is the second-largest east-flowing river of the Peninsula.

- Krishna river rises at Mahabaleshwar at an altitude of I336 m near the Jor village in the extreme north of district Satara, Maharashtra in the west, and meets the Bay of Bengal in Andhra Pradesh, on the east coast.

- Ecologically, this is one of the disastrous rivers in the world , in that it causes heavy soil erosion during the monsoon season.

- It is bounded by the Balaghat range on the north, by the Eastern Ghats on the south and the east, and by the Western Ghats on the west.

- The total length of the river from origin to its outfall into the Bay of Bengal is 1,400 km.

- The major part of the basin is covered with agricultural land accounting to 75.86% of the total area.

- The Krishna forms a large delta with a shoreline of about 120 km.

- Almatti Dam, Srisailam Dam, Nagarjuna Sagar Dam, and Prakasham Barrage are some of the major dams constructed on the river.

- Because it is fed by seasonal monsoon rains, the river’s flow undergoes great fluctuation during the year, limiting its usefulness for irrigation.

- Satara, Karad, Sangli, Bagalkot. Srisailant, Amaravati, and Vijayawada are some of the important urban and tourist centers on the bank of the river.

Tributaries of Krishna River

- Right bank : Venna, Koyna, Panchganga, Dudhganga, Ghataprabha, Malaprabha and Tungabhadra are the major right-bank tributaries

- Left Bank : Bhima, Dindi, Peddavagu, Halia, Musi, Paleru, and Munneru are the major left-bank tributaries

- The Koyna is a small tributary but is known for Koyna Dam . This dam was perhaps the main cause of the devastating earthquake (6.4 on Richter scale) in 1967 that killed 150 people.

- The Bhima originates from the Matheron Hills and joins the Krishna near Raichur after for a distance of 861 km.

- The Tungabhadra is formed by the unification of the Tunga and the Bhadra originating from Gangamula in the Central Sahyadri . Its total length is 531 km.

- At Wazirabad, it receives its last important tributary, the Musi , on whose banks the city of Hyderabad is located.

You can find many articles on GEOGRAPHY (part of GS I ) in our website. Go through these articles share with your friends and post your views in comment section.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on Telegram (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

- Click to email a link to a friend (Opens in new window)

- Click to share on X (Opens in new window)

- CEPA between India-UAE

- Criminal Procedure (Identification) Bill, 2022

Leave a Reply Cancel reply

General Studies

All Programmes

Study Material

The Koyna dam authorities, owing to the poor storage in dams across Satara district, have proposed cuts in water discharge for both irrigation and power generation.

About koyna dam.

- Location: It is one of the largest dams in the state of Maharashtra and is located at Koyna Nagar in Satara district.

- It is a rubble-concrete dam constructed on the Koyna River.

- The construction of this dam was completed in 1963 and is amongst the chief civil engineering projects built after the independence of India.

- The main purpose of dam is hydroelectricity with some irrigation in neighboring areas.

- Koyna Hydroelectric Project is the largest completed hydroelectric power plant in India, with a total installed capacity of 1,920 MW.

- The catchment area of the Koyna Dam blocks up the Koyna River and creates the Shivsagar Lake, which is roughly 50 km long.

- The dam plays a vital role in flood control during monsoon season.

Key Facts about Koyna River

- It is a tributary of the Krishna River in the western part of Maharashtra.

- Origin: It rises near Mahabaleshwar, a famous hill station in the Western Ghats.

- The river is just 100 meters wide and flows slowly.

- Unlike most of the other rivers in Maharashtra, which flow East-West direction, the Koyna River flows in North-South direction.

- The river merges with the Krishna River at Karad in the Satara district of Maharashtra.

- Due to its electricity-generating potential through the Koyna Hydroelectric Project, Koyna River is known as the Life Line of Maharashtra.

Q1) Which are the main tributaries of Krishna River?

The principal tributaries joining Krishna are the Ghataprabha, the Malaprabha, the Bhima, the Tungabhadra and the Musi.

Source: Koyna dam authorities propose water cuts for irrigation, power generation

Download PDF

Share this article.

© 2024 Vajiram & Ravi. All rights reserved

Koyna, India: A very prominent site of artificial water reservoir-triggered seismicity

- Published: 23 January 2022

- Volume 131 , article number 30 , ( 2022 )

Cite this article

- Harsh K Gupta 1

413 Accesses

2 Citations

Explore all metrics

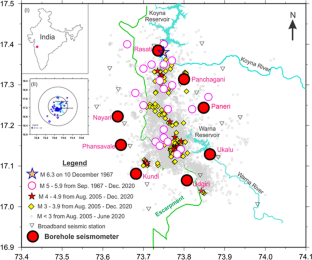

Anthropogenic activities such as gold and coal mining, oil and gas production, filling of artificial water reservoirs, harnessing of geothermal energy, etc., have induced/triggered earthquakes. Koyna dam, located in the Deccan volcanic province of India, was impounded in 1962, and soon after tremors were reported from the vicinity of Koyna dam. The largest triggered earthquake of magnitude ( M ) 6.3 occurred on 10 December 1967. The triggered earthquakes have continued until now and the region has experienced 22 events of an M ~5, over 200 events of an M ~4 and several thousand smaller events. The reservoir-triggered seismicity has continued until 2021, which is unique. Some of the early investigations, leading to drilling of a 3 km deep pilot borehole at Koyna for near-field studies of earthquakes, and a few recent results are summarised in this paper.

Research highlights

Koyna, located near the west coast of India, in the Deccan volcanic province is one of the most prominent sites of artificial water reservoir-triggered seismicity (RTS). Triggered earthquakes started soon after the impoundment of Shivaji Sagar lake created by Koyna dam in 1962 and have continued until now.

Unlike other RTS sites where triggered earthquakes did not continue for long, Koyna is still active, and it is estimated that RTS may continue for another one to two decades.

Detailed field work and analyses of earthquake data demonstrated that Koyna is a very suitable site for near-field studies of earthquakes: an observation that is much needed to validate earthquake genesis models.

International Continental Drilling Programme sponsored workshops and participation of experts from all over the world helped in deciding to dig a 3 km deep pilot borehole. The borehole was completed in June 2017.

Recent research studies further demonstrated that the Koyna region is under critical stress.

Studies under progress would help in designing the proposed ~7 km deep borehole laboratory.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Studies of Artificial Water Reservoir Triggered Earthquakes at Koyna, India: A Summary

Harsh K. Gupta

Artificial Water Reservoir-Triggered Seismicity (RTS): Most Prominent Anthropogenic Seismicity

Koyna, india, an ideal site for near field earthquake observations.

Committee of Experts 1968 Report on the Koyna Earthquake of December 11, 1967 – 1 and 2, Govt. of India Press, New Delhi, 75p.

Dutta A, Sar P, Sarkar J, Dutta Gupta S, Gupta A, Bose H, Mukherjee A and Roy S 2019 Archaeal communities in deep terrestrial subsurface underneath the Deccan Traps, India; Front. Microbiol. 10 1362, https://doi.org/10.3389/fmicb.2019.01362 .

Article Google Scholar

Geological Survey of India 1968 A Geological Report on the Koyna Earthquake of 11th December 1967, Calcutta, 242p.

Goswami D, Hazarika P and Roy S 2020 In situ stress orientation from 3 km borehole image logs in the Koyna seismogenic zone, Western India: Implications for transitional faulting environment; Tectonics 39 ( 1 ) e2019TC005647.

Goswami D, Roy S and Akkiraju V V 2019 Delineation of damage zones from 3 km downhole geophysical logs in the Koyna seismogenic zone, western India; J. Geophys. Res.: Solid Earth 124 , https://doi.org/10.1029/2018JB017257 .

Gupta H K 1983 Induced seismicity hazard mitigation through water level manipulation at Koyna, India: A suggestion; Bull. Seismol. Soc. Am. 73 679–682.

Google Scholar

Gupta H K 1992 Reservoir induced earthquakes ; Elsevier Scientific Publishing Company, Amsterdam, 364p.

Gupta H K 2001 Short term earthquake forecasting may be feasible at Koyna, India; Tectonophys. 338 353–357.

Gupta H K 2017 50 years of 10 December 1967 M 6.3 Koyna earthquake; J. Geol. Soc. India 90(6) 637–812.

Gupta H K 2018 Review: Reservoir triggered seismicity (RTS) at Koyna, India, over the past 50 yrs; Bull. Seismol. Soc. Amer. 108 2907–2918.

Gupta H K 2021 Understanding anthropogenic earthquakes; Curr. Sci. 120(9) 1415–1416.

Gupta H K and Iyer H M 1984 Are reservoir induced earthquakes of magnitude 5.0 at Koyna, India, preceded by pairs of earthquake of magnitude > 4.0?; Bull. Seismol. Soc. Am. 74 863–873.

Gupta H K, Mandal P and Rastogi B K 2002 How long will triggered earthquakes at Koyna, India continue?; Curr. Sci. 82 202–210.

Gupta H K, Narain H, Rastogi B K and Mohan I 1969 A study of the Koyna earthquake of Dec. 10, 1967; Bull. Seismol. Soc. Am. 59 1149–1162.

Gupta H K and Nayak S 2011 Deep scientific drilling to study reservoir triggered earthquakes in Koyna, western India; Sci. Drill. 12 53–54.

Gupta H K, Shashidhar D, Periera M, Mandal P and Dimri V 2006 Prediction of an M ~ 4 earthquake in the Koyna region comes true!; J. Geol. Soc. India 68 149–150.

Gupta H K, Rao N P, Roy S, Arora K, Tiwari V M, Patro B P K, Satyanarayana H V S, Shashidhar D, Mallika K, Akkiraju V V, Goswami D, Vyas D, Ravi G, Srinivas K N S S S, Srihari M, Mishra S, Dubey C P, Raju C V, Borah U, Reddy K C, Babu N, Rohilla S, Dhar U, Sen M and Rao Y J B 2014 Investigations related to scientific deep drilling to study reservoir-triggered earthquakes at Koyna; India Int. J. Earth Sci. 104 1511–1522.

Gupta H K, Rao N P, Shashidhar D and Mallika K 2008 The disastrous M 7.9 Sichuan earthquake of 12 May 2008; J. Geol. Soc. India 72 325–330.

Gupta H K and Rastogi B K 1976 Dams and earthquakes ; Elsevier Scientific Publishing Company, Amsterdam, 229p (translated into Russian in 1979 and Chinese in 1980).

Gupta H K, Rastogi B K and Narain H 1971 The Koyna earthquake of December 10, 1967: A multiple seismic event; Bull. Seismol. Soc. Am. 61 167–176.

Gupta H K, Rastogi B K and Narain H 1972a Common features of the reservoir associated seismic activities; Bull. Seismol. Soc. Am. 62 481–492.

Gupta H K, Rastogi B K and Narain H 1972b Some discriminatory characteristics of earthquakes near the Kariba, Kremasta and Koyna artificial lakes; Bull. Seismol. Soc. Am. 62 493–507.

Gupta H K, Shashidhar D, Periera M, Mandal P, Rao N P, Kousalya M, Satyanarayana H V S and Dimri V P 2007 Earthquake forecast appears feasible at Koyna, India; Curr. Sci. 93 843–848.

Johnston A C, Kanter L R, Coppersmith K J and Cornell C A 1994 The earthquakes of stable continental regions. Volume 3: Seismicity data sheets (part 1); Final report, No. EPRI-TR-102261-V3, Electric Power Research Institute.

Kerr R A and Stone R 2009 A human trigger for the great quake of Sichuan?; Science 323(5912) 322–322.

Krishna J, Chandrasekaran A R and Saini S S 1969 Analysis of Koyna accelerogram of December 11, 1967; Bull. Seismol. Soc. Am. 59(4) 1719–1731.

Krishnan M S 1960 Geology of India and Burma ; Higginbotham’s, Madras, 604p.

Michas G, Pavlou K, Vallianatos F and Drakatos G 2020 Correlation between seismicity and water level fluctuations in the Polyphyto dam, North Greece; Pure Appl. Geophys. 177(8) 3851–3870.

Mogi K 1963 Some discussions on aftershocks, foreshocks and earthquake swarms – The fracture of a semi-infinite body caused by an inner stress origin and its relation to earthquake phenomena; Bull. Earthq. Res. Inst. 41 615–658.

Narain H and Gupta H K 1968 Koyna earthquake; Nature 217 1138–1139.

Ohnaka M 1992 Earthquake source nucleation: A physical model for short-term precursors; Tectonophys. 211 249–278.

Pavlou K 2019 Relationship between observer seismicity and water level fluctuations in Polyphyto dam area (North Greece); J. Geogr. Environ. Earth Sci. Int. 21(2) 1–10.

Podugu N, Mishra S, Wiersberg T and Roy S 2019 Chemical and noble gas isotope compositions of formation gases from a 3 km deep scientific borehole in the Koyna seismogenic zone, Western India; Geofluids 2019(12) 1–16.

Podugu N, Yadav A, Mallika K, Goswami D and Uma Anuradha M 2018 Report on ICDP post-operations on international workshop on scientific deep drilling at Koyna, India, Pune 14–16, 2017; J. Geol. Soc. India 91(1) 120–124.

Rao N P, Arora K, Ponomarev A and Do Nascimento A F 2018 Introduction to the special issue fifty years after the 1967 Koyna earthquake – Lessons learned about reservoir seismicity (RTS); Bull. Seismol. Soc. Am. 108(5B) 2903–2906.

Rastogi B K and Mandal P 1999 Foreshocks and nucleation of small- to moderate-sized Koyna earthquakes (India); Bull. Seismol. Soc. Am. 89(3) 829–836.

Rekapalli R and Gupta H K 2021 Characterization of injection-induced seismicity at north central Oklahoma, USA; J. Seismol. 25 327–337.

Tandon A N and Chaudhry H M 1968 Koyna earthquake of 10 December 1967, India Meteorological Department, Scientific Report No. 59, 12.

Uma Anuradha M and Mallika K 2017 Reservoir loading parameters at Koyna and their correspondence with reservoir triggered seismicity; J. Geol. Soc. India 90 802–804.

Uma Anuradha M, Rekapalli R, Sudheer K, Jagadeesh P and Satyanarayana H V S 2021 Triggering of earthquakes at Koyna, India and hammer drilling for the pilot borehole. J. Nat. Hazards , https://doi.org/10.1007/s11069-021-04874-8 .

Download references

Acknowledgements

It is a pleasure to dedicate this paper to the special volume being brought out in the memory of Professor Gautam Sen. I had the good opportunity to be with Professor Sen at the University of Texas at Dallas for several years during 1970s. Our interactions continued as we met often during AGU meetings in the United States, and elsewhere. His contributions to geosciences are immense for which he would be always remembered, besides being a very good human being. The study reported here has been carried out with several scientists at NGRI, BGRL and elsewhere. They are too many to be mentioned. CSIR-NGRI and NASI are acknowledged for support.

Author information

Authors and affiliations.

CSIR-National Geophysical Research Institute, Hyderabad, Telangana, 500 007, India

Harsh K Gupta

You can also search for this author in PubMed Google Scholar

Contributions

The study reported here summarises a number of published studies on reservoir-triggered seismicity in Koyna, India, several of them by Harsh K. Gupta. A way forward towards achieving the target of establishing a deep borehole laboratory at Koyna, India is also presented.

Corresponding author

Correspondence to Harsh K Gupta .

Additional information

Communicated by N V Chalapathi Rao

This article is part of the Topical Collection: Deccan Traps and other Flood Basalt Provinces – Recent Research Trends.

Rights and permissions

Reprints and permissions

About this article

Gupta, H.K. Koyna, India: A very prominent site of artificial water reservoir-triggered seismicity. J Earth Syst Sci 131 , 30 (2022). https://doi.org/10.1007/s12040-021-01780-2

Download citation

Received : 28 May 2021

Revised : 15 September 2021

Accepted : 18 September 2021

Published : 23 January 2022

DOI : https://doi.org/10.1007/s12040-021-01780-2

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Reservoir triggered seismicity

- near field observations

- borehole investigations

- characteristics of earthquake sequences

Advertisement

- Find a journal

- Publish with us

- Track your research

IMAGES

VIDEO

COMMENTS

View PDF. CASE STUDY I: KOYNA HYDROELECTRIC POWER PLANT (KHPP) Introduction: Hydroelectric Power Plant: Hydro power plants convert potential energy of water into electricity. It is a clean source of energy .The water after generating electrical power is available for irrigation and other purposes. The first use of moving water to produce ...

Shivasagar lake. The Koyna Hydroelectric Project is the second largest hydroelectric power plant in India, just after the Tehri Dam Project. [1] It is a complex project with four dams including the largest dam on the Koyna River, Maharashtra, hence the name Koyna Hydroelectric Project. The project site is in Satara district .

Design Purpose: Hydro Electric Project and Irrigation River Sluice in the main dam till 1980. To use the static Project. head of height of reservoir, a dam foot Power House was 10. Hydro Electric Power Generation: constructed on right flank of the Dam during 1975 to 1980. ... A Case Study on Koyna Dam power demand in morning peak (7 to 11 am ...

SUBSCRIBE TO EMAIL ALERTS. Daily Updates of the Latest Projects & Documents. This report covers an appraisal of the first stage of the Koyna Hydro-Electric Power project for India which will include; a transmission line to Bombay, and a .

2 PROJECT DESCRIPTION 2.1 LOCATION Koyna project authority is proposing to set up a Hydroelectric Project of 2 x 40 MW on Koyna River nearly 150 m. downstream of Koyna dam in Tehsil - Patan, District -Satara, Maharashtra in India. The project is located to the east of the Koyna River near village Koynanagar, approximately 2 km down. The catchment

and the resultant hydro dynamic pressure built up in the system are kept at minimum acceptable levels, thus protecting the adjoining structures. This technique has been used for the first time in India as well in Asian region on Koyna Hydroelectric Project Stage-IV. This paper is a case study describing the various aspects along

Today the Koyna Hydroelectric Project is the second largest completed hydroelectric power plant in India having a total installed capacity of 1,960 MW. Due to its electricity generating potential, Koyna river is considered as the 'life line of Maharashtra'. The spillway of the dam is located at the center. It has 6 radial gates.

The Koyna Hydro Electric Project (KHEP) in Maharashtra, India is considered as the case study. The KHEP is the lifeline of Maharashtra, which has four stages to a total capacity of 1,960 MW [].The Koyna reservoir situated on the west coast of Maharashtra, India, alone has three powerhouses, two on the western side and one at the dam foot on the eastern side of the reservoir.

The Koyna Hydroelectric Project was amongst the rst water resource development projects built through a succession of four stages over the past 50 years in the state of Maharashtra. Its total installed generation capacity is now about 1,920 MW, and stage V is being undertaken while the scope of the project is still evolving.

The study indicated that the Koyna Hydroelectric Project yielded a benefit-cost ratio of 1.17 and Internal Rate of Return of 5%. These figures were 1.99 and 17.5%, respectively, for diversion of a higher quantum of 3.3 BCM of water. ... Koyna Hydro Electric Project (1950) Report and appendices, vol 1, Mumbai. ... This case study is a ...

Under Water Lake Piercing in Koyna Hydro Electric Project Stage-IV . ... This technique has been used for the first time in India as well as Asian in region on Koyna Project. This paper is a case study describing the various aspects from investigations to actual execution of this technique on said project. With the successful lake tapping ...

A BRIEF INTRODUCTION TO KOYNA HYDROELECTRIC POWER PLANT. Engineering. 1 of 12. Download now. Download to read offline. KOYNA HYDROELECTRIC POWER PLANT - Download as a PDF or view online for free.

Share this article. Koyna is a 1,920MW hydro power project. It is located on Koyna river/basin in Maharashtra, India. According to GlobalData, who tracks and profiles over 170,000 power plants worldwide, the project is currently active. It has been developed in multiple phases. Post completion of construction, the project got commissioned in 1962.

Koyna Stage IV Hydroelectric Project. The Koyna Hydroelectric Plant, a branch of the Krishna Basin, is a concrete dam 103.2 m above the foundation, built on the Koyna River, in Satara district, Maharashtra state, India. It is the second-largest hydroelectric project in the country and impounds water to generate 1960 MW in four phases.

The best known case is the 103 m high Koyna dam in India which was seriously damaged during the 1967 earthquake [1]. The largest damages were the horizontal cracks on both the upstream and the ...

2.2 Case Study—Koyna Dam. ... The Koyna Hydroelectric Project is India's largest completed hydroelectric power plant, with a total installed capacity of 1960 MW. Due to its electricity generation potential, the Koyna River is considered the lifeblood of Maharashtra. Koyna dam plays a vital role in flood control during the monsoon season.

The main purpose of the dam is hydroelectricity with some irrigation in neighbouring areas. Today the Koyna Hydroelectric Project is the largest completed hydroelectric power plant in India having a total installed capacity of 1,920 MW. Due to its electricity generating potential Koyna river is considered as the 'lifeline of Maharashtra'.

The Koyna Dam is the largest in the Indian state of Maharashtra, which is located on the state highway between Chiplun and Karad in the Koyana Nagar of Satara District. It is a type of rubble-concrete dam. It is India's second-largest completed hydropower plant. Koyna Hydroelectric Project consists of four stages of power generation.

Height of Koyna dam is 85.35 m above lowest river bed level. Length of dam is 807.72 m with gross storage capacity of 2980.68 MCM (105.25 TMC) and live storage capacity2835.54 MCM (100.125 TMC). The project supplies water to irrigate 247,009 ha. 6. of CCA in Satara & Sangli in addition to hydropower generation, with 1960 MW of installed capacity.

Anthropogenic seismicity has been observed due to filling of artificial water reservoirs, geothermal and natural oil/gas production, and gold/coal mining under favorable geological conditions. Among these, artificial water reservoir triggered seismicity (RTS) is most prominent, with over 200 sites globally where RTS has been observed, including 5 sites where earthquakes exceeding M 6 magnitude ...

The main purpose of the dam is hydroelectricity with some irrigation in neighbouring areas. Today the Koyna Hydroelectric Project is the largest completed hydroelectric power plant in India having a total installed capacity of 1,920 MW. Due to its electricity generating potential Koyna river is considered as the 'lifeline of Maharashtra'.

Koyna Hydroelectric Project is the largest completed hydroelectric power plant in India, with a total installed capacity of 1,920 MW. The catchment area of the Koyna Dam blocks up the Koyna River and creates the Shivsagar Lake, which is roughly 50 km long. The dam plays a vital role in flood control during monsoon season.

Soon after the occurrence of the Koyna earthquake of an M 6.3 on 10 December 1967, several field investigations were carried out in the Koyna region (Geological Survey of India 1968; Tandon and Chaudhry 1968; Gupta et al. 1969).One of the unique observations was the rotational displacement captured on a pillar at Donachiwadi (figure 2).A detailed isoseismal map was prepared by the Geological ...