To read this content please select one of the options below:

Please note you do not have access to teaching notes, the product life cycle revisited: an integrative review and research agenda.

European Journal of Marketing

ISSN : 0309-0566

Article publication date: 7 January 2022

Issue publication date: 2 February 2022

This paper aims to respond to calls in academia for an update of the product lifecycle (PLC). Through a systematic literature review, the authors provide an updated agenda, which aims to advance the PLC concept in research, teaching and practice.

Design/methodology/approach

The authors started by surveying 101 marketing academics globally to ascertain whether a PLC update was viewed necessary and beneficial in the marketing community and thereafter conducted citation analysis of marketing research papers and textbooks to ascertain PLC usage. The subsequent literature review methodology was split into two sections. First, 97 empirical articles were reviewed based on an evaluative framework. Second, research pertaining to the PLC determinants were assessed and discussed.

From the results of this review and primary data from marketing academics, the authors find that the method of predicting the PLC based on past sales has been largely unsuccessful and perceived as somewhat outdated. However, a new stream of PLC literature is emerging, which takes a consumer-centric perspective to the PLC and has seen more success at modeling lifecycles in various industries.

Research limitations/implications

First, the study outlines the most contemporary and successful methodological approaches to modeling the PLC. Namely, the use of artificial intelligence, big data, demand modeling and consumer psychological mechanisms. Second, it provides several future research avenues using modern market trends such as sustainability, globalization, digitization and Covid-19 to push the PLC into the 21st century.

Originality/value

The PLC has shown to be resolutely popular in management application and education. However, without a continued effort in academic PLC research to update the knowledge around the concept, its use as a productive management tool will likely become outdated. This study provides a necessary and comprehensive literature update resulting in actionable future research and teaching agendas intended to advance the PLC concept into the modern market context.

- Product lifecycle

- Research agenda

Iveson, A. , Hultman, M. and Davvetas, V. (2022), "The product life cycle revisited: an integrative review and research agenda", European Journal of Marketing , Vol. 56 No. 2, pp. 467-499. https://doi.org/10.1108/EJM-08-2020-0594

Emerald Publishing Limited

Copyright © 2021, Emerald Publishing Limited

Related articles

We’re listening — tell us what you think, something didn’t work….

Report bugs here

All feedback is valuable

Please share your general feedback

Join us on our journey

Platform update page.

Visit emeraldpublishing.com/platformupdate to discover the latest news and updates

Questions & More Information

Answers to the most commonly asked questions here

- Business Cycle

- Business Environment

- Consumer Protection

- Corporate Responsibility

- External Influences

- Globalisation

- Government Influence

- International Business

- Financial Risk

- Investment Appraisal

- Sources of Finance

- Competitive Advantage

- Customer Focus

- International Marketing

- Market Research

- Marketing Planning

- Marketing Strategies

- Product Launch

Product Life Cycle

- Product Portfolio

- Segmentation

- The Marketing Mix

- Continuous Improvement

- Customer Service

- Health and Safety

- Lean Production

- Location of Business

- Management of Change

- Merger and Acquisition

- New Product Development

- New Technology

- Product Development

- Production Process

- Research and Development

- Supply Chain

- Communications

- Developing People

- Equal Opportunities

- Managing Change

- Organising People

- Protecting People

- Recruitment and Selection

- Roles and Responsibilities

- Skills and Competencies

- Aims and Objectives

- Business Expansion

- Business Organisation

- Business Planning

- Business Start-Up

- Business Strategy

- Decision Making

- Sectors of Industry

- Stakeholders

- Strategic Planning

- Types of Organisation

- External environment

- External Environment

- eBook Collections

- Audio Case Studies

- Printed Books By Edition

- Employee Retention

- HR Software

- Hybrid Working

- Managing People

- Motivating People

- Performance Management

- Recruitment

- Time Management

- Training and Development

- Business Aquisition

- Business Growth

- Business Plan

- Business Startup

- Entrepreneurship

- Small Business

- Strategic management

- Types of Business

- Accountants

- Bookkeeping

- Budgeting and Cash Flow

- Business Debt

- Business Financing

- Business Funding

- Business Insurance

- Business Investment

- Business Loans

- Business Payments

- Business Taxation

- Market Trading

- Advertising

- Affiliate Marketing

- Business Branding

- Business Events

- Content Marketing

- Conversion Rate Optimisation

- Customer Experience

- Digital Marketing

- Email Marketing

- Lead Generation

- Link Building

- Marketing Agencies

- Marketing Strategy

- Pay Per Click Advertising

- Public Relations

- Social Media

- Business Efficiency

- Business Innovation

- Business Location

- Business Management

- Business Security

- Manufacturing

- Outsourcing

- Project Management

- Quality Management

- The Supply Chain

- Business Law

- Coronavirus

- Sustainable Business

- The Economy

- Stakeholder

- Ethical Business

- Business of Gambling

- Casino Bonuses

- Casino Games

- Casino Guides

- Mobile Gambling

- Online Casino

- Sports Betting

- Tips and Tricks

- Online Learning

- Schools and Colleges

- Students and Teachers

- Studying Internationally

- Universities

- Writing Services

- Cosmetic Procedures

- Cannabidiol (CBD)

- Cannabis/Marijuana

- Dental Care

- Mental Health

- Office Wellbeing

- Relationships

- Supplements

- Banking and Savings

- Credit Cards

- Credit Score and Report

- Debt Management

- International Money Transfers

- Investments

- Payday Loans

- Personal Insurance

- Personal Law

- Motor Accidents

- Motor Finance

- Motor Insurance

- Motoring Accessories

- Virtual Reality

- Gaming Accessories

- Mobile Gaming

- Online Gaming

- Video Games

- Buying Selling and Renting Property

- Construction

- Property Cleaning

- Property Investments

- Property Renovation

- Business Travel

- Camping Activities

- Travel Guides

- Travel Safety

- Visas and Citizenship

- Antiques and Art

- TV, Film & Music

- Mobile Apps

- Mobile Phone

- Photography

- Digital Transformation

- Crypto Exchange

- Crypto in Business

- Crypto Mining

- Crypto Regulation

- Crypto Trading

- Accessories

- Artificial Intelligence

- Programming

- Security & Privacy

- Software Development

- Web Analytics

- Website Design

- Website Development

- Website guides

- Website Hosting

- Guest Posting

- Membership Billing

- Membership Cancel

- Membership Invoice

- membership levels

- Your Profile

- Account Details

- Lost Password

No products in the basket.

Product Life Cycle

By: E. Raymond Corey, Noel Capon

Introduces the student to the concept of the product life cycle. The meaning and fundamental underpinnings of the product life cycle are presented. Further, the nature of market and competitive…

- Length: 11 page(s)

- Publication Date: Oct 1, 1978

- Discipline: Marketing

- Product #: 579072-PDF-ENG

What's included:

- Educator Copy

$4.95 per student

degree granting course

$8.95 per student

non-degree granting course

Get access to this material, plus much more with a free Educator Account:

- Access to world-famous HBS cases

- Up to 60% off materials for your students

- Resources for teaching online

- Tips and reviews from other Educators

Already registered? Sign in

- Student Registration

- Non-Academic Registration

- Included Materials

Introduces the student to the concept of the product life cycle. The meaning and fundamental underpinnings of the product life cycle are presented. Further, the nature of market and competitive forces at different stages in the life cycle, and the implications for managerial action, are discussed.

Oct 1, 1978 (Revised: Aug 16, 1985)

Discipline:

Harvard Business School

579072-PDF-ENG

We use cookies to understand how you use our site and to improve your experience, including personalizing content. Learn More . By continuing to use our site, you accept our use of cookies and revised Privacy Policy .

- Accountancy

- Business Studies

- Commercial Law

- Organisational Behaviour

- Human Resource Management

- Entrepreneurship

- Learn Product Management | Beginner to Advanced Tutorial

- What is Product Management?

- 5 Reasons Why Product Management is so Important

Product Life Cycle (PLC) | Stages and Case Study of Apple

- Pros and Cons of Product Management

People/Roles involved in Product Management

- Product Management Manager

- Who is Product Manager?

- How to Become a Product Manager Without Experience ?

- Job Description (JD) for a Product Manager

- Product Manager Salary in India 2024

- Chief Product Officer | Definition, Role, and Responsibility

- What Does a Technical Product Manager Do?

- 8 Stages of New Product Development Process

- A Complete Guide to a Successful Product Launch

- What is Churn in Product Management? Calculation, and Its Impact on Business

- What is Customer Acquisition Cost - CAC Explained

- Difference between a Project Manager and Product Manager

- Product Manager Vs Owner

What is Product Life Cycle (PLC)?

Product Life Cycle (PLC) is a model that illustrates how a product progresses through stages during its time on the market. It serves as a tool for businesses to understand how their products evolve and how to manage them efficiently. This concept plays a role in making decisions regarding product development, marketing strategies, pricing strategies, and distribution channels. In today’s paced world of business and innovation, it is crucial to grasp the Product Life Cycle (PLC).

Table of Content

Stages of Product Life Cycle (PLC)

Case study of product life cycle of apple, key takeaways from product life cycle (plc):.

- The PLC is a concept in marketing and product management that helps businesses plan strategically and make informed decisions about their products.

- This cycle represents the stages that a product goes through starting from its introduction to its decline in the market.

- Understanding these stages allows companies to adapt their strategies effectively maximizing profits and ensuring long-term success for their products.

-copy.webp)

1. Introduction

The introduction stage signifies the entry of a product into the market. The initial stage is typically associated with an increase in sales since it involves introducing the product to consumers. During this phase, businesses incur expenses for marketing and research and development (R&D) as they strive to raise awareness and stimulate demand for their product. Companies need to invest in marketing and create distribution channels to ensure that their product is easily accessible to customers. The objective is to establish a presence in the market and generate interest. During this phase, pricing strategies often revolve around two approaches:

- Penetration pricing, where a lower price is initially offered to gain market share,

- Skimming pricing, where a higher price is charged at first to recover development costs.

The growth stage witnesses a surge in sales as consumers become more aware of the product’s existence and its advantages. This growth is fueled by word-of-mouth favourable reviews and effective marketing campaigns. In this phase, businesses strive to expand their market share by scaling up production and distribution. With the increasing demand, competition may intensify as new players try to capitalise on the opportunity. As the product gains recognition, pricing strategies might shift towards a competitive approach. Companies may also introduce variations or extensions of the product aimed at market segments.

3. Maturity

The maturity stage represents the peak of sales and market penetration for the product. Competition typically reaches its point during this period, and attention shifts from attracting customers to retaining existing ones. Price stability and product differentiation become a feature of this stage. Ongoing marketing endeavours aimed at maintaining both market share and brand loyalty. Companies frequently make investments in improving their products, adding features, and implementing marketing campaigns to ensure their products remain relevant and competitive. Furthermore, they may explore opportunities in markets.

In the decline phase, sales of the product start to decrease due to changing consumer preferences, market saturation, or the emergence of alternatives. Companies must decide whether to discontinue the product or continue selling, it with marketing efforts. As existing inventory price reductions or discounts may be necessary, some companies may choose to reinvent or rebrand the product or find markets to extend its life cycle. Ultimately, the decision to withdraw or revive the product depends on its profitability and how well it aligns with the company’s strategy.

Introduction Phase

During the phase from 2007 to 2008, Apple introduced the iPhone, which brought about a significant transformation in the smartphone industry. To generate awareness and create excitement surrounding their product, Apple invested heavily in marketing and promotional activities. The innovative design and user-friendly interface of the iPhone captured the interest of tech enthusiasts. Capitalising on this wave of enthusiasm, Apple implemented a pricing strategy that involved charging prices initially.

Growth Stage

In the years that followed from 2009 to 2012, the iPhone experienced growth. Apple expanded its range of offerings by introducing models like the iPhone 3G, 4, and 4S. The launch of the App Store in 2008 played a role in fueling this growth by creating an ecosystem that catered to both developers and users alike. To meet increasing demand, Apple focused on scaling up production and distribution, while establishing partnerships with telecom carriers worldwide. Product differentiation also played a role during this stage as Apple offered storage capacities and introduced new features such as improved cameras and faster processors.

Maturity Phase

By 2013, the iPhone had reached maturity as it faced competition from Android-based smartphones. The market became saturated with options for consumers to choose from. To keep its position in the market, Apple put a lot of emphasis on improving its products. Released a series of iPhones, including the 5, 6, 7, and 8 models. They also introduced the Plus and SE versions. Alongside this, Apple carried on with its marketing campaigns that aimed to build brand loyalty and make sure customers were satisfied. Moreover, they expanded into markets, which helped solidify their position as a leading smartphone company.

Declining Stage

In years (2019 onwards), the iPhone entered a stage of decline where it faced obstacles, like market saturation and the rise of competitors. To tackle these challenges, Apple has adjusted its pricing strategies and introduced the affordable iPhone SE. Additionally, the company has heavily invested in services, like Apple Music, Apple TV+, and Apple Arcade to diversify its revenue streams and keep customers engaged. By focusing on refreshing its products and building an ecosystem around its devices, Apple has been able to prolong the lifespan of the iPhone and minimize the impact of market decline.

The Product Life Cycle (PLC) is a framework that helps businesses navigate their product’s complex journey in the market. By understanding the four stages of introduction, growth, maturity, and decline, companies can make choices regarding product development, pricing, marketing, and distribution. Effectively managing a product throughout its life cycle can lead to success and a competitive advantage in today’s dynamic business environment.

Please Login to comment...

Similar reads.

- Geeks Premier League 2023

- Geeks Premier League

Improve your Coding Skills with Practice

What kind of Experience do you want to share?

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

Exploit the Product Life Cycle

- Theodore Levitt

How to convert a tantalizing concept into a managerial instrument of competitive power

Most alert and thoughtful senior marketing executives are by now familiar with the concept of the product life cycle. Even a handful of uniquely cosmopolitan and up-to-date corporate presidents have familiarized themselves with this tantalizing concept. Yet a recent survey I took of such executives found none who used the concept in any strategic way whatever, and pitifully few who used it in any kind of tactical way. It has remained—as have so many fascinating theories in economics, physics, and sex—a remarkably durable but almost totally unemployed and seemingly unemployable piece of professional baggage whose presence in the rhetoric of professional discussions adds a much-coveted but apparently unattainable legitimacy to the idea that marketing management is somehow a profession. There is, furthermore, a persistent feeling that the life cycle concept adds luster and believability to the insistent claim in certain circles that marketing is close to being some sort of science. 1

- TL Theodore Levitt was a professor emeritus of marketing at Harvard Business School and former editor of Harvard Business Review.

Partner Center

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

THE PRODUCT LIFE CYCLE THEORY

In this paper, the production life cycle theory is explained and find ways to adapt and use this theory related to regional development.

Related Papers

Seyhan Sonmez

Over its two hundred-year history, international trade theory witnessed increasing role of knowledge. Following classical theories of Smith (1776), and Ricardo (1817), based solely on labor as an element of cost, neoclassical contributions made it possible to take capital and other production factors into account through the concept of opportunity cost, undermining knowledge. Even the modern trade theories of Heckscher-Ohlin-Samuelson used two-factor models including just labor and capital. As of 1960s, parallel to the debate over Leontief Paradox, new theories of international trade began to cover knowledge and related concepts like skilled labor, technology gap, product cycle, etc. According to theories, how and who can trade with whom, we will try to explain this situation in this study.

eric wanyamah

Journal of International Public Administration

Heidi Jane Smith

This study explores the financial sustainability of subnational governments in four different countries. Scholars argue that subnational fiscal capacity helps local governments deliver better public services and provide public goods, which in turn helps to promote economic growth. While administrative control by the central governments contributes to reducing moral hazard from the soft budget constraints, bottom-up strategies to manage fiscal profligacy also need attention. The study first provides understanding about the characteristics of central-local governance and management of subnational government debt of each country. Then, we test our hypotheses regarding local fiscal capacity and administrative control, including political-economic factors that may affect debt spending by local governments. Our findings show that subnational fiscal sustainability improves when the central governments have clear rules to intergovernmental transfers in place and more (market) liberal policies, meanwhile when subnational governments have a more fiscal capacity and less intergovernmental transfers they are able to manage their debt more soundly.

Ashley Hunte

Clement Tisdell

This article concentrates on the global location of production of television receivers as a case study. The aim is to see if this accords with Vernon’s international product cycle theory or whether some modifications of the theory are required. The historical evolution of the global television industry is outlined and the global pattern of demand for television sets is explored, partly to relate the location of demand to the location of television production. Production cycles involved in television manufacture and its international location are then carefully explored both for black-and-white sets and for colour television. China’s rise to become the world’s major producers of television sets is given particular attention. Conclusions are drawn about the continuing relevance of the international product cycle and the need to modify Vernon’s original perceptions about it.

Journal of Fashion Marketing and Management

William Oxenham , Nancy Cassill

World Development

Kimmo Kiljunen

Liladhar Suthar

Joachim Schleich

Based on data for eight OECD countries this paper empirically explores the factors driving exports in the automotive sector between 1991 and 2008. The factors considered explicitly account for possible lead market effects which have recently been identified in the literature as relevant factors in studying the export potentials of certain technologies. Econometric results suggest that exports in the automotive

International Journal of Studies in Nursing

limor malul

RELATED PAPERS

Gastroenterology

Michael Harnish

Frontiers in Pharmacology

Akshay Anand

Jon Sticklen

TATuP - Zeitschrift für Technikfolgenabschätzung in Theorie und Praxis

Dirk Scheer

Datuk Maralelo Siregar Siregar

Journal of Innovation in Health Informatics

Simon de Lusignan

Archiv für katholisches Kirchenrecht

Matthias Ambros

WSEAS Transactions on Mathematics

Domingo López Rodríguez

Anar İsmayılov

Heavy metals and arsenic concentrations in water, agricultural soil, and rice in Ngan Son district, Bac Kan province, Vietnam

Journal of Aircraft

instname:Universidad Libre

RUTH REYES MORA

Diagnostic and Interventional Radiology

sagar tomar

International Journal of Livestock Production

Skender Muji

The journal of immunology

Werner Müller

World Journal of Veterinary Science

Journal of Food Science

Branka Levaj

Journal of the Acoustical Society of America

Valerie Hazan

Stéphane Loire

Nursing Practice Today

ayfer karadakovan

Taryn E Travis

Claudia Campetella

IFIP International Federation for Information Processing

Bart De Decker

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Coca-Cola Company: Product Life Cycle

Introduction, background to the study.

The US beverages industry has witnessed rampant growth over the past decades (Spelman Research, 2003, p. 2). This is evident in the large number of domestic and foreign investors who have ventured into the industry. The core operations of the industry entail the production and marketing of diverse non-alcoholic beverages, mineral water, and carbonated beverages. Due to the industry’s profitability potential, the degree of rivalry amongst competing firms has increased.

According to Adam & Armstrong (2005, p. 60), increment in competition amongst rival firms tends to reduce the industry’s level of profitability. This arises from the fact that firms compete to attain significant market share compared to their competitors.

One of the firms operating in this industry is Coca Cola Company. Over the years, the firm has managed to develop a relatively high competitive advantage compared to its competitors. The firm’s management team has appreciated the importance of conducting market trend analysis. This enables the firm to develop effective operational strategies. Through consumer market research, the firm has appreciated the need to meet customers’ needs satisfactorily.

This results from the realization of the fact that consumers change their consumption behavior over time. According to PRLog (2008, para. 1), consumers have become health conscious in their consumption patterns. The report asserts that increment in consumer health awareness has culminated from information explosion regarding beverages and soft drinks. This has been translated into an increment in demand for a soft drink amongst the consumers. In addition, changes within the competitive environment have played a significant role in the operation of the firm. Some of Coca-Cola’s key competitors include PepsiCo and Cadbury Schweppes (Spelman Research, 2003, p. 4).

According to Spelman Research (2003, p. 6), Coca-Cola Company managed to attain a significant market share of 30% in the US industry compared to that of PepsiCo and Cadbury Schweppes which were 27% and 11% respectively. Nestlé’s market share was 3% while other small firms’ market share was 29%. Considering the changes within the external environment, firms need to incorporate effective operational strategies. To attain this, the firm has integrated the concept of product diversity. The firm has been attaining this through continuous product development. This contributes towards the firm meeting consumers’ demands.

This report is aimed at analyzing the product life cycle with specific reference to Coca-Cola Company.

Definition of the product life cycle is given and the four stages of the product life cycle are identified and analyzed. These include introduction, growth, maturity, and decline. In addition, the report gives an analysis of the impact of these stages on the firms marketing strategies. These relate to the product, promotion, pricing, and distribution. Finally, a conclusion and recommendations are given.

Product Life Cycle

According to 12 Manage (2010, para. 7), the Product Life Cycle (PLC) is defined as the stages that a given product undergoes in its development. For a firm to succeed in an environment characterized by intense competition, it is paramount for the firm to incorporate effective entrepreneurial strategies. One of the key strategies that a firm’s management team can integrate relate to invention and innovation.

The resultant effect is that the firm can attain a high competitive strategy relative to its competitors. In its operation, Coca-Cola Company has effectively incorporated the concept of product innovation. As a result, the firm has introduced several segments. These include carbonates, fruit juices, bottled water, functional drinks, and Ready-To-Drink (RTD) tea and coffee. These products are traded under different brand names (Spelman Research, 2003, p.7). For these products to succeed in the market, it is paramount for the firm’s management team to consider the concept of PLC.PLC has 4 stages which include;

Introduction stage

Growth stage, maturity stage, decline stage.

The concept of PLC is based on the same concept of the biological life cycle. Over the years, PLC has become very important in the operation of firms. This is because firms are increasingly incorporating product development to attain their profit maximization objective. As result, the firm’s management teams are being committed to ensuring that this objective is attained within the PLC. This makes it clear that the firm’s management teams must incorporate the concept of PLC in the process of formulating and implementing diverse marketing strategies.

Upon successful development of a product, the product has to be introduced in its specific target market. This contributes towards the target customers accessing the product. This is the firm’s first step towards ensuring that there is sufficient market awareness regarding the product. Significant cost is incurred at the introduction phase. For instance, the successful introduction of a product in the market is determined by the effectiveness with which the firm has tested the market.

In addition, the cost of introducing the product into the market will also be increased by the need to create market awareness through promotion. At this stage, the firm’s ratio of promotion expenditure to sales is very high. The cost involved at this stage is also increased by the need to secure an effective distribution channel (Free presentation slides, 2008, para. 7).

To compete with firms producing a variety of functional products, Coca Cola Company introduced Bubble Buzz which is a tea product. The need to develop the new product was instigated by a change in consumer demands for the soft drink. According to Afsha, Chin-Yun, Audrey, and Nicolas (2006, p. 6), there is a shift in consumer consumption patterns. Currently, consumers do not prefer carbonated drinks. The product was specifically designed to meet the physiological, nutritional, and hydrating demands of the customers. According to Marketing Teacher (2010, para. 5), the need for the firm to attain instant profit is not a key consideration in this phase. As a result, the introduction stage is characterized by relatively low market size and slight growth.

At this stage, the product has already penetrated the market. As a result, the firm’s level of profit is increased due to a high rate of sales growth. In addition, firms attain economies of scale at this phase enabling them to develop their competitive advantage about pricing. The intensity of competition also increases at this stage. This arises from the fact that a large number of potential investors are attracted to venture into the industry. As a result, it becomes vital for firms to incorporate strategies aimed at building the brand. One of the strategies relates to market communication strategies.

This is attained through an increment in the firm’s commitment to its promotion campaign enabling the product to survive in the market. In addition, the firm’s market share at this stage starts to stabilize. In marketing its Bubble Buzz product within the RTD tea segment, the Coca-Cola Company has witnessed a relatively high level of market share. By 2003, the segment was the fastest growing. According to Spelman Research (2003, p. 3), the market for RTD tea has witnessed an annual growth of 6%. This growth has been sustained for the last 5 years.

The maturity stage is universal in all the products. At this stage, the degree of rivalry amongst competing firms is very high. This results from the fact that all firms are fighting to retain their market share. In addition, firms receive the highest level of profits at this stage. However, growth in sales is at a low rate until they stabilize.

At this stage, the market for the product shrinks leading to a reduction in the level of profit within the industry. The shrink may result from a shift in consumer tastes and preferences or the introduction of other products which are more innovative.

Impact of PLC on marketing strategies

Promotion strategy.

At this phase, product awareness is vital. Thus, the company must strategize on how to market its product/service. This can only be attained through the incorporation of a promotion strategy. Depending on the target market, the firm has to determine the best promotion method at the introduction phase. However, a firm needs to consider Integrated Marketing Communication (IMC) at this phase.

According to Adam& Armstrong (2005, p. 65), IMC entails diverse methods of creating market awareness. This will ensure that information awareness is effectively created within the target market. In introducing Bubble Buzz in the market, the Coca-Cola Company utilized diverse promotion methods. These included advertising, public relation, sales promotion, and incorporation of emerging information communication technologies. This enabled the product to be widely recognized in the domestic and international markets.

According to Marketing Teacher ( 2010, para. 4), there is a low probability of a firm making a profit about new products being introduced in the market during their introduction stage. At this stage, the firm’s management team should formulate effective monitoring strategies. These strategies should be aimed at ensuring that the product penetrates the market and start to grow. In addition, monitoring the products at this phase will safeguard against the products from being withdrawn.

Pricing strategy

Because consumers are price-sensitive, it is paramount that the management teams formulate an effective pricing strategy. In their purchasing patterns, price is one of the variables that consumers consider. This makes it important for firms to decide on the best pricing strategy to utilize in this stage. Because the product is new to the market at this phase, a penetration pricing strategy should be incorporated.

The strategy entails setting the price of the product at a relatively low price compared to its competitors. As a result, the price set will appeal to the consumers making them consider purchasing the product. The ultimate result is that a firm can penetrate the market and attain a large market share. However, a penetration pricing strategy should be used when the market size of the product is large and the intensity of competition is high (Free presentation slides, 2008, para. 9). For Coca-Cola Company to effectively penetrate its target market for Bubble Buzz, penetration pricing was used.

Considering the intensity of competition at the growth stage, it is paramount for firms to consider attaining price competitiveness. At this stage, the firm has already attained economies of scale. This will make it possible for the firm to set the price of its products at a low point.

The maturity stage has an impact on the firm’s pricing strategy. This arises from the intensity of competition characterizing this stage. This makes the maturity stage to be characterized by a price war.

At the decline stage, most of the firms cut the price of their products to attract and retain customers. However, consumers are attracted to more innovative products. In extreme situations, the product may be withdrawn.

Product and Expansion strategy

For a firm to be competitive, continuous product innovation should be undertaken (Adam & Armstrong, 2005, p. 66). At this juncture, the market is by now saturated. This is because a large number of similar products are introduced in the market by competing firms. At this stage, the firm needs to integrate product differentiation. This will enable the firm’s products to be unique.

The maturity stage has an impact on the firms financing and marketing activities. Due to the intensity of competition, the firm has to be keen on the marketing strategy adopted. This is because there is a high probability of the competitor adopting the same strategy. The effect is that the strategy will not be effective. To attain a competitive edge during the growth phase; firms have to consider strategies aimed at attaining a high market share through expansion.

Some of the strategies that firms consider integrating relate to the formation of joint ventures, takeovers, and formation of alliances (Marketing Teacher, 2010, para. 8). This enables firms to enable the firm to position themselves in the market. The above expansion strategy culminates in an improvement in the firm’s production efficiency. To implement these strategies, a significant amount of finance is required. This makes it vital for the firm to make an optimal financing decision. In addition, finances are paramount at this stage since it enables the firm to conduct product development more effectively. This can be achieved through the incorporation of product innovation leading to an improvement in the quality of products.

In the decline juncture, the organization must look for alternative markets for its products where they can offer them at a lower price. In addition, the firm should reduce the amount incurred in its production cost.

For a firm to be successful in the long term, it should consider developing effective operational strategies. One of the strategies that should be incorporated relates to product innovation. Upon introducing the product in the market, the firms’ management team needs to consider its life cycle. Most products have 4 stages. Each stage has different characteristics about the market. By considering these stages, a firm can able to formulate and implement effective marketing strategies.

This is because these stages have an impact on the strategies relating to the product, price, promotion, and distribution. According to the stage of the product, a firm can be able to adjust its marketing strategies. The ultimate effect is that the firm can develop a high competitive advantage.

Recommendations

Coca-Cola Company should consider the following in marketing its products.

- Conduct continuous evaluation of the products PLC.

- Adjust its marketing strategies according to the various stages of its products.

Reference List

Adam, K. & Armstrong, D., 2005, Principles of marketing. Australia: Pearson Education.

Afsha, B., Chin-Yun, C., Audrey,L. & Nicolas, R. 2006. Example of a marketing plan: bubble buzz. New York: University of New York. Web.

Free Presentation Slides. 2008. Introduction phase of product life cycle concept. New York: Amazon Kindle Review. Web.

Marketing Teacher. 2010. The product life cycle. New York: Marketing Teacher Limited. Web.

PRLog. 2008. Soft drink production in the US . Washington: Bharatbook. Web.

Spelman Research. 2003. US soft drink market. New York: Independent Investment Research. Web.

12 Manage. 2010. Analyzing industry maturity stages: explanation of product life cycle of Levitt. London; The Executive Fast Track. Web.

Cite this paper

- Chicago (N-B)

- Chicago (A-D)

StudyCorgi. (2021, December 11). Coca-Cola Company: Product Life Cycle. https://studycorgi.com/coca-cola-company-product-life-cycle/

"Coca-Cola Company: Product Life Cycle." StudyCorgi , 11 Dec. 2021, studycorgi.com/coca-cola-company-product-life-cycle/.

StudyCorgi . (2021) 'Coca-Cola Company: Product Life Cycle'. 11 December.

1. StudyCorgi . "Coca-Cola Company: Product Life Cycle." December 11, 2021. https://studycorgi.com/coca-cola-company-product-life-cycle/.

Bibliography

StudyCorgi . "Coca-Cola Company: Product Life Cycle." December 11, 2021. https://studycorgi.com/coca-cola-company-product-life-cycle/.

StudyCorgi . 2021. "Coca-Cola Company: Product Life Cycle." December 11, 2021. https://studycorgi.com/coca-cola-company-product-life-cycle/.

This paper, “Coca-Cola Company: Product Life Cycle”, was written and voluntary submitted to our free essay database by a straight-A student. Please ensure you properly reference the paper if you're using it to write your assignment.

Before publication, the StudyCorgi editorial team proofread and checked the paper to make sure it meets the highest standards in terms of grammar, punctuation, style, fact accuracy, copyright issues, and inclusive language. Last updated: September 28, 2023 .

If you are the author of this paper and no longer wish to have it published on StudyCorgi, request the removal . Please use the “ Donate your paper ” form to submit an essay.

Dissipation-based life cycle impact assessment of mineral resource use—a review, case study, and implications for the product environmental footprint

- CRITICAL REVIEW

- Open access

- Published: 27 April 2024

Cite this article

You have full access to this open access article

- Markus Berger ORCID: orcid.org/0000-0002-3012-7470 1

173 Accesses

Explore all metrics

Impacts of mineral resource use on the availability of resources can be assessed using a broad range of methods. Until recently, life cycle inventory (LCI) and life cycle impact assessment (LCIA) models have been based on resource extraction. As extracted resources are not necessarily “lost” for future use, recent methodological developments have shifted the focus from resource extraction to resource dissipation . This paper aims at reviewing dissipation-based LCIA methods, testing them in a case study, analyzing potential implications for the product environmental footprint (PEF), and providing recommendations for future method development.

Five recently developed LCIA methods have been reviewed and compared based on 22 criteria, such as the forms and time horizons of dissipation considered, scientific publication, and number of characterization factors (CFs). Additionally, the abiotic depletion potential (ADP) method has been included to serve as a non-dissipation-based reference. All methods are tested in a case study on a theoretical product, designed solely for demonstration purposes, and consisting of 1 kg of the metals aluminum, cobalt, copper, molybdenum, nickel, and zinc. In addition to the absolute LCIA results, the contributions of metal production stages and individual resource extractions/emissions have been investigated. Finally, normalization and weighting have been carried out to analyze consequences of replacing ADP with the new dissipation-based methods in the context of PEF.

Results and discussion

Most recently developed LCIA methods take a long-term perspective, cover emissions of resources to the environment (and partly technosphere), and vary in the number of CFs and resources covered. The case study results obtained by ADP are dominated by the molybdenum dataset; the results of the dissipation-based LCIA methods are strongly influenced by the cobalt dataset. All results are strongly sensitive to the LCI database used (ecoinvent or GaBi). Normalization and weighting revealed that the mineral resource use impact result dominates the aggregated PEF score (57%), when using the currently recommended ADP model. Shifting from the resource extraction-based ADP to dissipation-based models can reduce the contribution to 23% or < 1% depending on the method.

The development of methods addressing mineral resource use in LCIA has shifted from resource extraction to dissipation. The analyzed methods are applicable and lead to different findings than the extraction-based ADP. Using the newly developed methods in the context of PEF would significantly change the relevance of the mineral resource use impact category in comparison to other environmental impacts.

Avoid common mistakes on your manuscript.

1 Introduction

In life cycle assessment (LCA) practice, impacts of resource use on the environment and human health are assessed by various impact categories, such as land use change, acidification, or eco- and human toxicity. However, assessing the impacts of resource use (in particular mineral resource use) on the availability of the resources themselves - and even the question of whether this should be assessed in environmental LCA at all - is highly controversial (Sonderegger et al. 2017 ).

An expert group of the UNEP-SETAC Life Cycle Initiative has reviewed 27 existing life cycle impact assessment (LCIA) methods, analyzed them in a criteria-based comparison, and clustered them into four categories: depletion methods, future efforts methods, thermodynamic accounting methods, and supply risk methods (Sonderegger et al. 2020 ). Based on this review and discussions at the Pellston Workshop ® 2019, a safeguard subject for mineral resources within the area of protection natural resources has been defined, LCIA methods have been recommended for relevant questions, and recommendations for future method development have been provided (Berger et al. 2020 ).

One of the key challenges identified by the expert group was the fact that current methods exclusively focus on the extraction of resources, neglecting the dissipative resource uses. The latter can be described as a use of resources that renders them inaccessible for future use. For example, an emission of metal dust into the environment resulting from the abrasion in car brakes is considered “lost” because, technologically and economically, it would be too difficult to recover. Therefore, the expert group’s final recommendation was that “the concept of dissipative resource use should be defined and integrated in future method developments” (Berger et al. 2020 ).

This call for scientific development has been addressed by various research groups. Recent methodological developments include frameworks for dissipation-based assessment of resource use (Beylot et al. 2020 ; Charpentier Poncelet et al. 2019 ), life cycle inventory (LCI) concepts (Beylot et al. 2021 ; Lai and Beylot 2022 ), and LCIA methods (Ardente et al. 2022 ; Charpentier Poncelet et al. 2021 ; Dewulf et al. 2015 ; Owsianiak et al. 2022 ; van Oers et al. 2020 ).

With a focus on LCIA, this paper aims at reviewing the abovementioned methods in a criteria-based evaluation, testing them in a case study, analyzing the implications for the product environmental footprint (PEF) (EU 2021 ), and providing recommendations for future method development. The paper is the outcome of a project conducted on behalf of the International Council on Mining and Metals (ICMM) with participation of various metal associations. First, the methods for the criteria-based literature review and for conducting the case study are introduced (Section 2 ). Subsequently, the results of the literature review (Section 3.1 ), the case study (Section 3.2 ), and the implications for PEF (Section 3.3 ) are presented. Based on the findings, conclusions are drawn and recommendations for the ongoing development of dissipation-based LCIA methods are provided (Section 4 ).

2.1 Literature review

Of the abovementioned dissipation-based methodological developments, only the applicable LCIA methods, i.e., those providing characterization factors and not conceptual frameworks only, have been selected:

Environmental dissipation potential (EDP) (van Oers et al. 2020 )

Abiotic resource project (ARP) (Owsianiak et al. 2022 )

Average dissipation rate (ADR) (Charpentier Poncelet et al. 2021 )

Lost potential service time (LPST) (Charpentier Poncelet et al. 2021 )

Price-based impact assessment (Ardente et al. 2022 )

Additionally, the established and frequently applied abiotic depletion potential (ADP) method (van Oers et al. 2002 ) has been included to serve as a non-dissipation-based reference. The six methods are reviewed, briefly summarized, and evaluated in a criteria-based comparison. For this, the evaluation scheme of the Life Cycle Initiative’s expert group on resources (Sonderegger et al. 2020 ) was used as a template. In consultation with all project partners involved (ICMM and metal associations), the scheme was modified leading to the 22 evaluation criteria shown in Table 1 .

As the terms used for the criteria “form of dissipation considered” are used differently between researchers and research communities, they are briefly defined here. Dissipative “emissions into the environment” are emissions of resources from the technosphere into the environment which render them inaccessible for other users as they cannot be recovered due to technological or financial constraints. Examples include the abrasion of metal dust from car brakes mentioned above. “Emissions within the technosphere” refer to resource flows inside the technosphere which also make them inaccessible because of too-low concentrations (e.g., alloying elements in non-functional recycling (Reller 2016 )) or too-low volumes (e.g., metals in small landfills). “Occupation in use” (also termed borrowing use) refers to resources which are currently inaccessible for other users because they are embodied in products (e.g., steel in buildings), and it is debated whether this should be considered as a form of dissipation or not (Frischknecht 2016 ). Related to that the “hibernation in use” is a form of dissipation in which resources are inaccessible because they are contained in products which are not used anymore but have not been taken to recycling facilities yet (Kapur and Graedel 2006 ). Typical examples are metals in old smart phones which users often keep at home even if they are not used anymore.

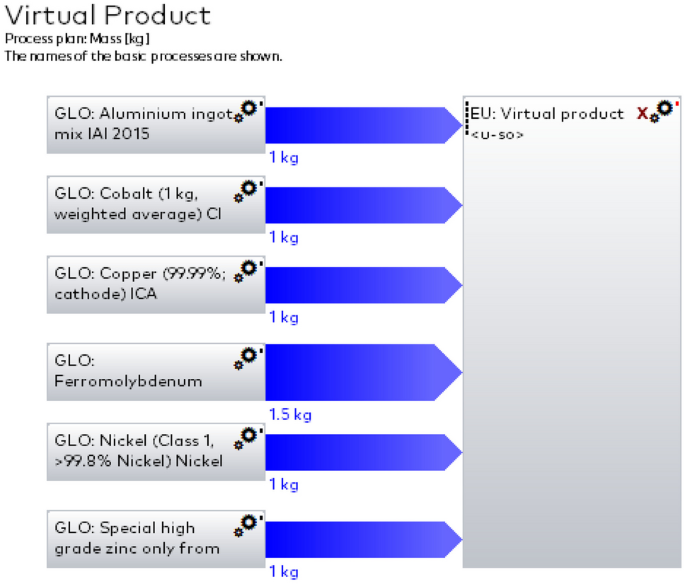

2.2 Case study

The six LCIA methods are tested in a case study on a theoretical product, designed solely for demonstration purposes, and consisting of 1 kg of the following metals: aluminum, cobalt, copper, molybdenum, nickel, and zinc. As shown in Fig. 1 , the product system was modelled in the GaBi software using the GaBi 2022.2 database (Sphera 2022 ). To model 1 kg of molybdenum, 1.5 kg of ferromolybdenum is used to consider the metal content. Out of the six LCIA methods, only ADP was included in GaBi already. The other methods were implemented manually as new environmental quantities by assigning the respective CFs to the resource emissions (e.g., aluminum emission to air) (EDP, ARP, Price) or resource extractions (e.g., bauxite mining from geologic reserves) (ADR, LPST). It should be noted that the GaBi database lists the extraction of bauxite as the elementary flow (in contrast to ecoinvent which lists aluminum), but the ADR and LPST methods provide CFs for aluminum only. In line with other resource LCIA methods (like ADP), a conversion factor of 4 (4 kg of bauxite to produce 1 kg of aluminum) has been used to determine a CF for bauxite.

Life cycle inventory model of the theoretical product analyzed in the GaBi software

To allow for a more detailed analysis of the underlying metal production system, the aggregated metal datasets have been replaced by disaggregated LCI models provided by the respective metal associations. These LCI models are the basis from which the metal datasets available in GaBi and ecoinvent are derived.

While the bill of materials of the theoretical product comprises 1 kg of each metal, it should be noted that the LCI of each metal contains the extraction and emission of several resources in different quantities resulting from the mining and refining of each metal including their background systems for electricity generation, production of auxiliaries, transport, etc. To analyze what is driving the results, the contributions of individual resource extractions or emissions to the six impact category results have been analyzed. Further, the theoretical product has been modelled again using ecoinvent 3.7 datasets (Ecoinvent 2022 ) to analyze the sensitivity of results to LCI databases.

While the focus of this study was on the cradle-to-gate datasets provided by the metal associations involved in this project, it is important to also consider a life cycle perspective as the hotspots of resource use may shift from the production (extraction impacts) to the use and end-of-life phases (dissipation impacts). Based on a material flow analysis (MFA) study quantifying dissipative losses for a set of metals throughout their life cycles (Helbig et al. 2020 ), metal-specific dissipation rates have been determined for the use phase (0–8%) and end-of-life phase (6–71%). According to Helbig and colleagues ( 2020 ), end-of-life dissipative losses end up entirely in the technosphere. It should be noted that the EDP and ARP methods consider dissipation to the environment only and the ADR and LPST methods are applied to resource extractions (see Section 3.1 ). For this reason, end-of-life dissipation has been considered in the price-based method only whose developers explicitly address dissipation into the technosphere (Ardente et al. 2022 ; Beylot et al. 2021 ). As dissipation rates can vary drastically for different products and user behaviors, a worst-case life cycle scenario has been added in which the entire metal content of the product gets dissipated to the environment.

2.3 Implications for PEF

To test the potential implications of using the newly developed dissipation-based methods in the context of the product environmental footprint (PEF) (EU 2021 ), the LCIA results have been normalized using global per capita normalization factors. These are provided by PEF (ADP), by the method developers (EDP and ARP), or by own calculations (ADR, LPST100) based on the global annual extractions multiplied by their CFs and divided by the world population. Finally, the normalized results have been weighted using the PEF weighting factor of 7.6% for mineral resource use (EF 3.0 2022 ). By aggregating the results with the other 15 normalized and weighted impact category results, the contribution of resource use measured by dissipation-based methods has been analyzed and compared to the currently recommended method (ADP).

3 Results and discussion

3.1 literature review.

Before presenting and discussing the results of the criteria-based comparison, the six LCIA methods are described by summarizing the main ideas of their characterization models.

3.1.1 Description of methods

The abiotic depletion potential (ADP) of a resource was originally defined as a ratio of a resource’s annual production to the square of the resource’s crustal content, normalized to the same ratio of the reference resource antimony leading to the common unit of antimony equivalents (Guinée and Heijungs 1995 ). The ADP of a product system is calculated by multiplying all resource extractions reported in the LCI by the respective CFs and summing the results. Thus, the method uses physical scarcity of resources in the earth crust as an indicator to measure the impact of resource use. After a data update in 2002 (van Oers et al. 2002 ), the method was revised in 2009 by separating it into two categories: ADP for fossil fuels and ADP for elements. The ADP for elements was updated in 2016 (CML-IA 2016 ) and methodologically enhanced in 2019 using recent crustal content data and cumulated production from 1970 to 2015 instead of single-year production rates which can change considerably (and thus alter the CFs) over time (van Oers et al. 2019 ). In the case study presented below, ADP is used in its 2016 version (CML-IA 2016 ), which is also implemented in the product environmental footprint (EF 3.0 2022 ).

In contrast to assessing the extraction of resources by means of ADP, the environmental dissipation potential (EDP) aims at assessing the long-term dissipative losses of resources, i.e., the emission of resources to the environment (van Oers et al. 2020 ). The characterization model, which is used to determine the CFs, is similar to the one of the original ADP method (Guinée and Heijungs 1995 ) as it comprises a ratio of resource extraction in a reference year to the squared crustal content of the resource. However, this ratio is not normalized to the ratio of antimony (in ADP of elements) but to the ratio of copper, and, thus, EDP is expressed in copper equivalents. The central assumption in the characterization model is that all resources extracted in the reference year will be dissipated in the very long-term perspective. In contrast to ADP, the CFs are not multiplied by resource extractions of the product system but by the emission of resources to the environment. It should be noted that the authors of EDP also provide conceptual characterization models to measure impacts of technosphere hibernation and occupation in use (van Oers et al. 2020 ), which are not considered in this work as applicable CFs are not available yet.

Building up on the idea of defining emissions of resources to the environment as dissipative losses, the abiotic resource project (ARP) developed a classification model to differentiate metal emissions to the environment into dissipative and non-dissipative flows (Owsianiak et al. 2022 ). The basic assumption behind this concept is that metal emissions to the environment are only dissipative if both of the following two conditions apply. First, they “originate from a source with a concentration higher than a reference (concentration in upper continental crust) reflecting what is accessible for humans within the considered time span” (Owsianiak et al. 2022 ). For example, copper leached out from a rain pipe can be dissipative, as the copper originates from a copper mine extracting the metal from geologic reserves (with a concentration higher than the average copper concentration in the upper continental crust). In contrast, copper emissions from coal-fired power plants are not dissipative flows, as the copper contained in coal is not a geologic reserve but an impurity (with a concentration lower than the average copper concentration in the upper continental crust). As a second criteria, a metal dissipation is only considered dissipative, if “the current annual rate of total anthropogenic emissions results in a steady state concentration in the receiving environment that is below a reference concentration” (Owsianiak et al. 2022 ). Hence, metal emissions (even if originating from geologic reserves) are not dissipative if the concentration in the receiving compartment is above the metal’s concentration in the upper continental crust. The ARP method is not a characterization model but a classification model, which can be combined with other emission-based characterization models. In this study, it is combined with the EDP method described above. As current LCI databases do not specify whether metal emissions originate from ores, fossil fuel impurities, or other sources, the first criteria to identify non-dissipative emissions could not be applied in the case study presented in this paper. However, for the method evaluation shown below, the method is included in its original version including both criteria.

To avoid the uncertainty related to resource emissions used as proxy for dissipative losses in current LCI databases (unclosed mass balances in some datasets, origin of emissions from resources or impurities, concentrations in receiving compartments), Charpentier Poncelet et al. ( 2021 ) follow a different approach. The authors developed two LCIA methods which use the concept of dissipation in their characterization models, but the resulting CFs are applied to the resource extraction and not resource emission inventory flows. The first method, ADR, assesses impacts of resource extraction based on their average dissipation over time, considering global average dissipation rates (ADR) which have been determined for each metal based on dynamic material flow analysis data. ADR depends on the function of resource dissipation over time and is calculated as the inverse of the total service time, which can be understood as the area below the dissipation function measured in kg ⋅ years per kg extracted. The second LCIA method, LPST, denotes the lost potential service time within a certain timespan, which is defined as the difference between the optimum service time (no dissipation, rectangular area of kg ⋅ years per kg extracted in a dissipation over time diagram) and the actual service time (area below the dissipation function, kg ⋅ years per kg extracted) within this time span (Charpentier Poncelet et al. 2021 ). In this work, a time horizon of 100 years is used, and the indicator is termed LPST100. It should be noted that these methods are based on the global average dissipation rates of resources, and the dissipation of resources extracted in the product system under study can be different. In the opinion of the author, this potential mismatch between the LCI and the LCIA levels can lead to counterintuitive results. For example, if a product system (in theory) does not have any dissipative losses, it will still show impact due to its resource extraction and the average (not product specific) dissipation rates of these resources. Vice versa, if a product is made from 100% recycled content, no resource extraction will be reported in the LCI and, thus, the LCIA result will be zero regardless of the amount of resources that gets emitted from the product system into the environment. Such results are nor “wrong,” but the difference between dissipation rates reported in the LCI (specific) and applied in the LCIA methods (average) should be kept in mind when interpreting the results.

After having proposed a new inventory scheme to clearly list dissipative resource flows in the LCI (Beylot et al. 2021 ), Ardente et al. ( 2022 ) propose a price-based impact assessment method. Assuming that market prices reflect “the multiple, complex and varied functions and values held by mineral resources” (Ardente et al. 2022 ), the authors use resource prices averaged over a 50-year timespan as CFs to assess the impact of dissipative resource losses. In this work, the CFs are applied to the emission of resources to the environment as reported in the GaBi database, as the dissipation-specific inventories (Beylot et al. 2021 ) are not available for the analyzed metals yet.

3.1.2 Criteria-based comparison

The complete evaluation of the six LCIA methods described above against the 22 criteria shown in Table 1 is presented in a spreadsheet in the supplementary material S1 . In the following, the main findings and differences between the methods are presented and discussed.

Concerning the classification scheme according to which a working group of the UNEP Life Cycle Initiative recommended methods for different questions (Berger et al. 2020 ), all methods except for the price-based method are considered to address the question: “How can I quantify the relative contribution to the depletion of mineral resources?”. This is not surprising, as dissipation directly contributes to resource depletion, and the UNEP working group recommended the development of dissipation-based methods for this question. In contrast, the price-based method addresses the question: “How can I quantify the relative (economic) externalities of mineral resource use?”.

Concerning the time scale, all methods address the long-term impacts of resource dissipation except for the price-based method. The latter assesses the short-term impacts reflected by market prices, which is consistent with the previously proposed LCI approach (Beylot et al. 2021 ). This also takes a short-term perspective and considers resource flows into waste disposal facilities or non-functional recycling as dissipative. In addition to the long-term perspective, the authors of the EDP method (van Oers et al. 2002 ) also propose (not yet operational) concepts for the short- and medium-term perspectives. Also the LPST can be calculated for different time horizons. In this context, it should be noted that the terms short-, medium-, and long-term are neither clearly nor consistently defined. Often short-term is considered as < 5–10 years, mid-term around 25 years, and long-term > 100 years (Arvidsson et al. 2020 ; Schulze et al. 2020 ) or even > 500 years (Dewulf et al. 2021 ).

The characterization models of EDP, ARP, ADR and LPST consider emissions of resources into the environment as a form of dissipation. Additionally, the conceptual methods of the EDP authors as well as the dynamic material flow models underlying the ADR and LPST characterization models define emissions into the technosphere (e.g., landfill or non-functional recycling) as dissipative. None of the methods considers occupation in use or hibernation in the technosphere (e.g., unused products such as old smartphones not taken to recycling yet) a relevant form of dissipation.

The CFs of classical resource LCIA methods, such as ADP, are applied to (multiplied by) the resource extraction flows of the LCI. In contrast, the CFs of most dissipation-based methods are applied to the emission of resources (EDP and ARP) or to flows of dissipative resource losses from specific LCIs (price-based method). Two exceptions to this are the ADR and LPST methods, whose CFs are applied to the resource extraction flows as their characterization models describe the average dissipation rates per kg extracted resource.

The characterization models (classification model for ARP) and underlying main assumptions are described above. With regard to normalization, the analysis revealed that all methods except for ADR and LPST provide applicable normalization factors (inverse of global per-capita impacts). For the latter methods, normalization factors have been calculated by using extraction data from the ADP method, multiplying the resource extractions by their corresponding ADR and LPST 100 CFs, and dividing it by the world population to obtain per capita impacts.

None of the method publications discusses the option of weighting the impact assessment results of resource dissipation to compare or aggregate them to other impacts. To illustrate the applicability and effects of weighting, the LCIA results of the theoretical product are normalized and weighted using the weighting set of the product environmental footprint (PEF) (EF 3.0 2022 ).

All LCIA methods are published in peer-reviewed scientific journals. The data quality of the characterization models is considered high for the extraction (ADP and EDP) and price-based models as global production, crustal content, and market prices of resources are well reported. The data quality of the other characterization models is considered medium due to uncertainties associated with the use of modelled data (fate models in ARP and dynamic material flow models in ADR and LPST). However, in both cases, it should be noted that central assumptions, such as crustal content being a proxy for ultimately extractable reserves, complete dissipation of current extraction in the long-term future, or market prices being a proxy for the value of resources are not less relevant than numeric data uncertainty.

In addition to data quality of the characterization models, the quality of the LCI data to which the CFs are connected is also important. In general, it can be said that the quality of resource extraction data needed for ADP, ADR, and LPST is higher than the quality of resource emission data, which is used as a proxy for dissipative flows into the environment. This is because resource extractions are comparatively easy to measure and well reported. In contrast, emissions of resources do not necessarily represent dissipative losses (as addressed by ARP), and the comparison of resource inputs (extraction) and outputs (emissions and product) often shows inconsistent mass balances.

Concerning the practical implementation of the LCIA methods, it can be said that all methods provide applicable CFs which are publicly available, with only ADR and LPST being not published open access. The number of CFs ranges from 18 for ADR and LPST to 108 for EDP. While ARP, ADR, and LPST cover mainly metals, the other methods also provide CFs for minerals. At this point (November 2023), the methods are not available in the LCA software with the exception of ADR and LPST being implemented in SimaPro. However, an older version of ADP (van Oers et al. 2002 ) is implemented in all of the above-mentioned LCA softwares. The effort for manually implementing the LCIA methods in the GaBi software is considered low for ADP, ADR, and LPST, as only new environmental quantities (impact categories) need to be created and CFs for the resource extraction flows need to be entered. The implementation of the other impact categories requires more effort, as the names of the elementary flows in the method publications (e.g., copper) need to be matched to a list of emissions in the software (e.g., copper [heavy metals to air], copper [heavy metals to freshwater], etc.).

3.2 Case study

The absolute impact assessment results of the theoretical product’s mineral resource use are shown in Table 2 for the production phase only, along the life cycle based on average dissipative losses during the use and end-of-life phases, and for a scenario assuming complete dissipation of the product’s metal content. Even though some categories share the same reference unit, a comparison is only possible between EDP and EDP+ARP. The 31% lower result in the latter in the production phase shows the relevance of classifying resource emissions as dissipative or non-dissipative and only including those emissions in the characterization which dissipate. It should be noted that the 31% reduction was obtained by including the second dissipation criteria only (emissions end up in a compartment below the reference concentration) as the first criteria (emission originates from a reserve) could not be applied as current LCI databases do not contain this information.

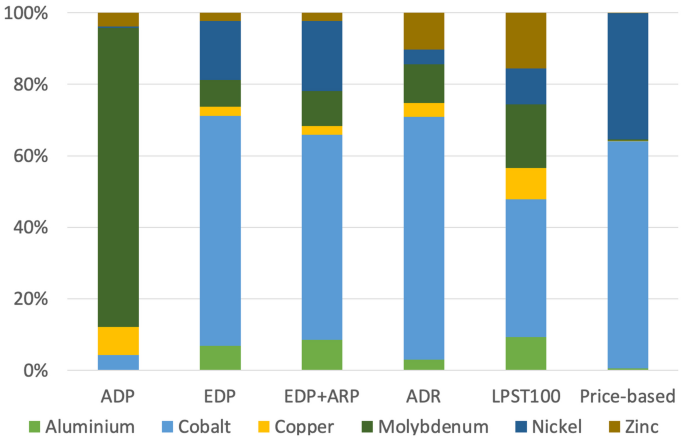

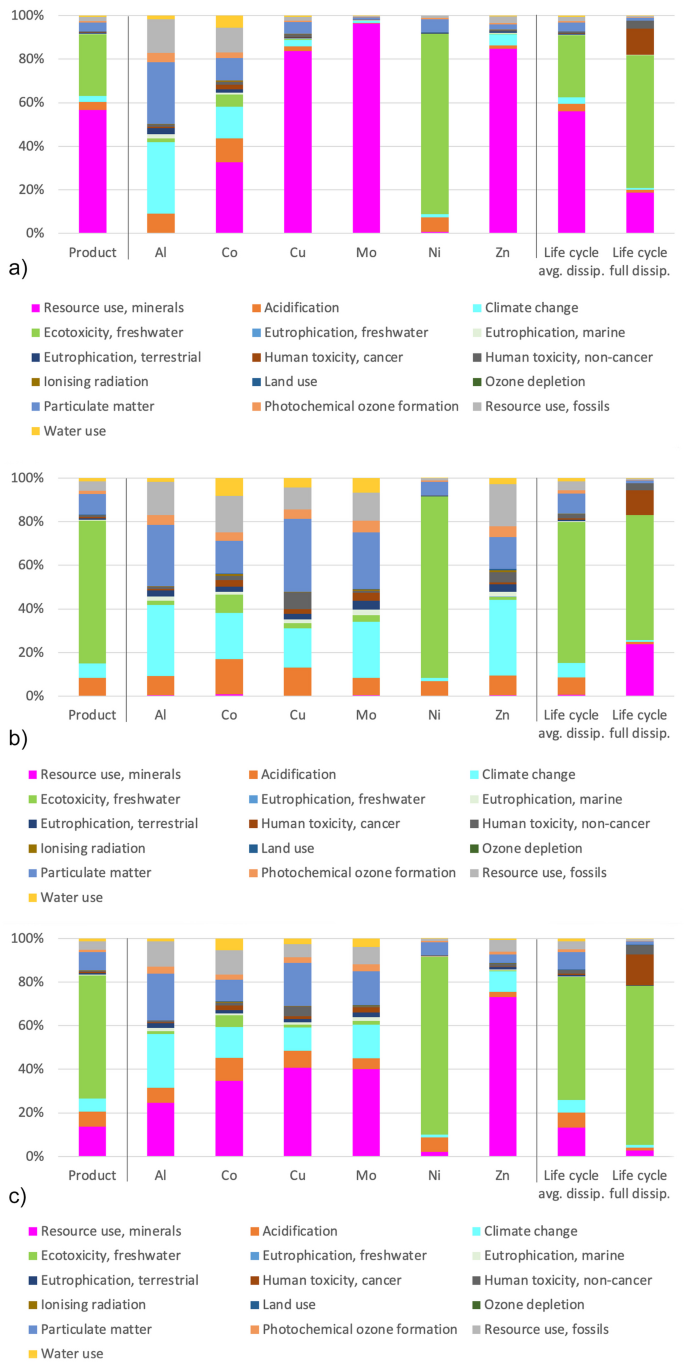

As absolute results are not comparable across impact categories and hard to interpret without comparisons, the following analysis is conducted on a relative scale to determine the contribution of the metal datasets to the result of each impact category obtained during the production phase. As shown in Fig. 2 , the “traditional” ADP is dominated by the molybdenum dataset, which plays a minor role in the results of the dissipation-based impact categories whose results are dominated by cobalt and partly nickel. Results of the EDP and EDP+ADR methods and results of ADR and LPST100 show similar patterns concerning the contribution of the individual metal datasets. The differences between these two method groups and between ADP and the price-based method can be explained by different methodological settings concerning the LCI and LCIA. While EDP, EDP+ARP, and the price-based methods use resources emitted during the production of the metals as relevant elementary flows, ADP, ADR, and LPST100 rely on resource extractions required for the metal production. Further, the characterization factors by which these elementary flows are multiplied reflect resource scarcity (ratio of extraction/dissipation to reserves in ADP/EDP), global average dissipation rates (ADR and LPST100), or market prices (price-based method). When interpreting those results, it should be kept in mind that a theoretical product is analyzed consisting of 1 kg of each of the metals, which eases comparability but does not reflect the material composition of real products in which metals like cobalt are present in much lower percentages.

Contribution of the individual metal datasets to the LCIA results in the extraction-based impact category abiotic depletion potential (ADP) and the dissipation-based impact categories environmental dissipation potential (EDP), abiotic resource project (ARP), average dissipation rate (ADR), lost potential service time (LPST), and the price-based model

In addition to aggregated metal datasets implemented in the GaBi database, some of the metal industry associations involved in this study provided disaggregated versions of their metal LCI models. In this way, the contribution of individual production stages to the total impact category results could be analyzed. As shown in Fig. S1 in the supplementary material, electrolysis is dominating the impacts in the aluminum production (except for ADR and LPST100). In contrast, the results for copper are dominated by the copper concentrate production. While for copper, the metal emissions originate from the concentration step directly, the emissions of the aluminum electrolysis are mainly caused by the Chinese electricity grid mix contained in the background system. Given that current LCI databases do not differentiate whether emissions result from geologic reserves or impurities, metal dissipation of aluminum production can be overestimated.

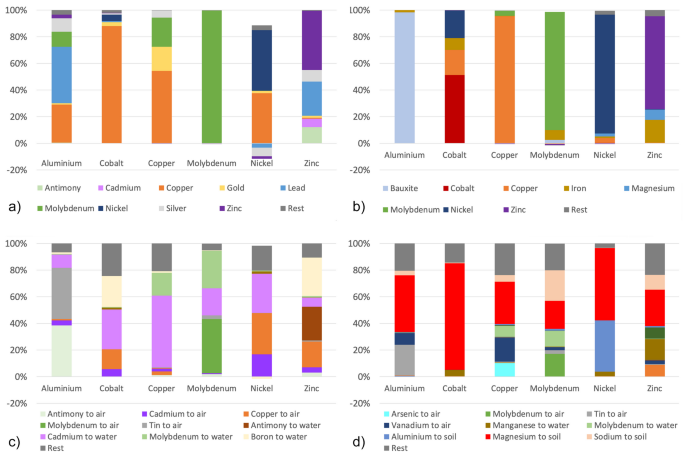

In addition to analyzing the contribution of production stages to total results, the contribution of individual elementary flows (resource extractions or emissions) has been analyzed for the production phase. This allows for a deeper understanding of the results because e.g., a copper dataset contains the extraction and emission of many more resources than copper in its LCI. For the impact categories applying their CFs to resource extractions (ADP and LPST100), the extraction of the target metals usually causes a relevant contribution to the LCIA result of the respective metal dataset (Fig. 3 a and b). That is, molybdenum extraction contributes significantly to the ADP result of the molybdenum dataset, and zinc extraction contributes significantly to the LPST100 result of the zinc dataset. For aluminum and cobalt, a different outcome can be observed in the ADP results, which are dominated by the extraction of copper and lead (for aluminum) and the extraction of copper (for cobalt). This can be explained by the fact that the ADP CFs for bauxite and cobalt, which denote their geologic scarcity, are relatively low compared to the CFs of the other resource extractions. In contrast, the average dissipation rates of these ores/metals are comparably high, leading to a significant contribution of these resource extractions in LPST100 (Fig. 3 b).

Contribution of resource extractions to the impact categories ADP ( a ) and LPST100 ( b ) as well as contribution of resource emissions to the impact categories EDP+ARP ( c ) and the price-based method ( d ) during the production phase

The results of the impact categories applying their CFs to resource emissions (EDP+ARP and the price-based method, shown in Fig. 3 c and d) are usually not influenced by emissions of the target metal. Only for the molybdenum dataset, the emission of molybdenum to air and freshwater contributes significantly to the EDP+ARP result. In general, the results of many metal datasets in this impact category are dominated by the emission of cadmium to freshwater (Fig. 3 c). In contrast, the results of most metal datasets in the price-based impact category are dominated by the emission of magnesium to industrial soil (Fig. 3 d). This shows that dissipative losses of the target elements (e.g., nickel emissions in the nickel dataset) are low compared to other emissions and/or that the environmental dissipation potential (EDP) and market price (price-based method) of the target metals is relatively low.

To analyze the sensitivity of the results to the LCI database, the analysis of the production phase has been repeated using metal datasets from the ecoinvent 3.7 database (Ecoinvent 2022 ). As shown in in Fig S2 in the supplementary material, results vary significantly depending on the database used. For ADP, the ecoinvent results are always larger than the GaBi results ranging from a factor of 1.2 (zinc) to 16.8 (nickel). Besides ADP, the largest differences can be found in the price-based LCIA method in which ecoinvent results can be larger by a factor of 70.2 (copper) or lower by a factor of 7.7 (nickel). For the other impact categories, results obtained by ecoinvent and GaBi vary by factors of 5 lower (cobalt) to a factor of 10.4 higher (nickel). Thus, results are highly sensitive to the database used which can be explained by data- and/or modelling-related differences. Data differences include data sources, data collection methods, reference regions, and reference years. Different modelling approaches include different tailing models or allocation procedures, to name a couple. Beyond the dissipation-based resource impact categories, the different metal emissions reported in the GaBi and ecoinvent databases will also affect the results of toxicity impact categories. However, as the toxicity potentials of metal emissions are not correlated to their dissipation potentials, differences between the GaBi and ecoinvent results in the dissipation categories are not the same as in the toxicity categories. Further, different metal components of the theoretical product (nickel in ecotoxicity and a metal mix in human toxicity) and different metal emissions (aluminum and chloride in ecotoxicity as well as arsenic and lead in human toxicity) dominate the results of the toxicity categories.

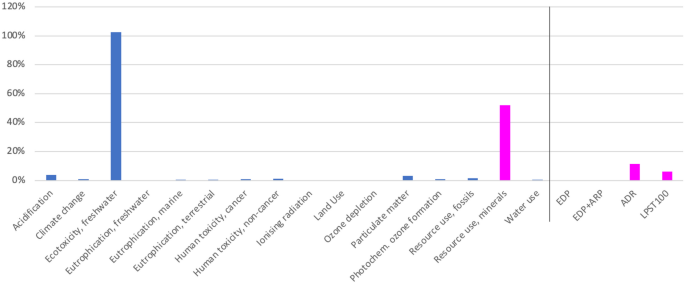

3.3 Implications for PEF

To test the implications of using the newly developed dissipation-based methods in the context of the product environmental footprint (PEF) (EU 2021 ), the LCIA results have been normalized (using global per capita normalization factors), weighted (using the EF 3.0 weighting factor of 7.6% for mineral resource use), and aggregated with the other 15 PEF impact categories. The production phase’s normalized results in Fig. 4 show that the theoretical product causes a high specific contribution in the impact categories ecotoxicity (102%) and mineral resource use (52%). This can be interpreted as the theoretical product causing the same impact as one average global citizen per year in the ecotoxicity category and half of the annual per person impact in the mineral resource category. The specific contribution in the other impact categories is negligible. The normalized results of the theoretical product along its life cycle are shown in Fig. S3 in the supplementary material.