Operations Management Implementation

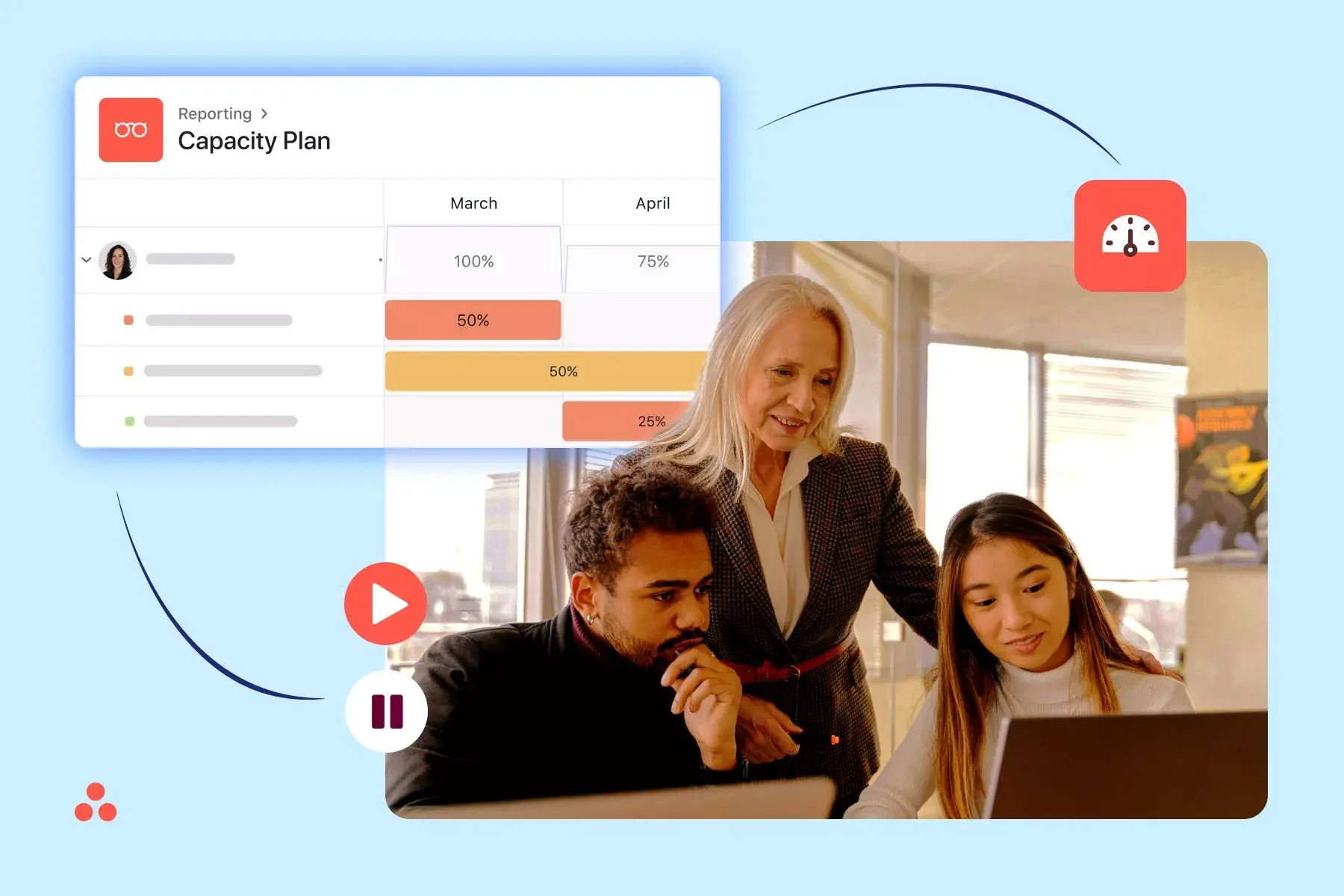

Operations Management Implementation, as an enhanced system with predictive scorecards, provides valuable insights to what is occurring in the process.

Operations Management Implementation involves the design, management, and control of processes in the production of goods and services. Included in operations management are the development and utilization of resources throughout organizational supply chains at both the tactical and operational levels.

Tactical issues include:

- Facilities structure and layout

- Equipment selection

- Equipment replacement

Operational issues include:

- Scheduling and control

- Inventory management

- Material handing

- Maintenance

Operations management

Operations management converts inputs (e.g., materials and labor) into outputs (e.g., products and services) so that the organization benefits. Operations Management ensures that business operations are efficient in terms of using as few resources as needed, and effective in terms of meeting customer requirements. Operations management balances costs with revenue for the purpose of maximizing net operating profit.

An Implementation System

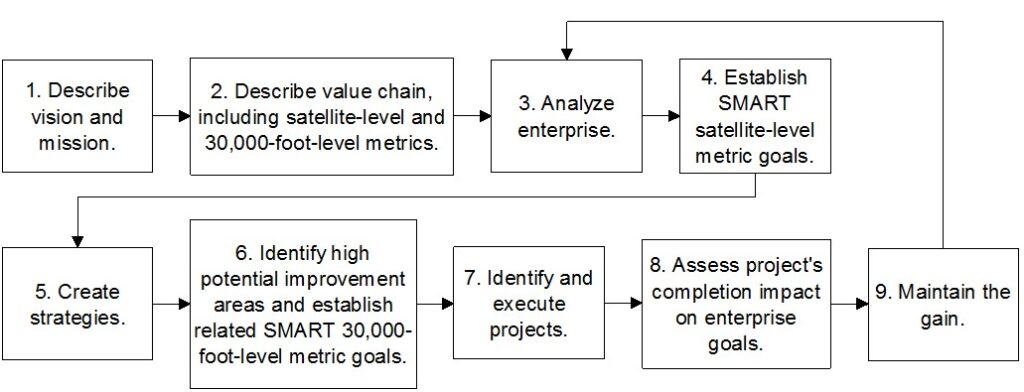

Integrated Enterprise Excellence (IEE) provides a long-lasting structure for implementing and the objectives of Operations Management. IEE addresses the operational management scorecard and improvement issues described in a 1-minute video :

IEE is a sustainable business management governance system, which integrates:

- Business scorecards

- Process improvement

An IEE system can help organizations move toward the three Rs of business (everyone is doing the Right things and doing them Right at the Right time). IEE provides the framework for innovation and continual improvement.

The existence and excellence of a business depends on more customers and cash, or, E=MC 2 . As a business way of life, IEE provides the organization orchestration to achieve more customers and cash through its 9-step implementation roadmap.

An Enhanced Approach for Operations Management Implementation

For additional information about Integrated Enterprise Excellence (IEE) see:

- Business Management Implementation: IEE Articles, Videos, Books

- An Operations Management Implementation to address Executive Challenges

- An Operations Management Implementation that transitions historical reported dashboards and scorecards to predictive reports (10 application illustrations shown)

- Using within an Operations Management Implementation a predictive performance metric system

Application of IEE to Creation of a Long-lasting Business Process Management (BPM) and Management Information System (MIS) Implementation

How to benefit from the IEE system in operations management with its Enterprise Performance Reporting System (EPRS) software (which provides predictive scorecard reporting and a process improvement system so the big picture benefits) is described in:

- How to Avoid Commonplace Business Management System Software Problems

- How to Avoid Commonplace Management Information System Software Problems

- How to Avoid Commonplace Business Process Management Software Problems

- How to Avoid Commonplace Lean Six Sigma Problems

Contact Us through an e-mail or telephone call to set up a time for a discussion on how your organization might gain much from an Integrated Enterprise Excellence Business Process Management system. Or, a Zoom meeting can be schedule directly:

E-mail ( [email protected] ) or call us (+1.512.918.0280), if you encounter difficulties setting up a Zoom session directly or want to schedule another time that is not available in the Zoom-meeting calendar.

Privacy Overview

- Business Essentials

- Leadership & Management

- Credential of Leadership, Impact, and Management in Business (CLIMB)

- Entrepreneurship & Innovation

- Digital Transformation

- Finance & Accounting

- Business in Society

- For Organizations

- Support Portal

- Media Coverage

- Founding Donors

- Leadership Team

- Harvard Business School →

- HBS Online →

- Business Insights →

Business Insights

Harvard Business School Online's Business Insights Blog provides the career insights you need to achieve your goals and gain confidence in your business skills.

- Career Development

- Communication

- Decision-Making

- Earning Your MBA

- Negotiation

- News & Events

- Productivity

- Staff Spotlight

- Student Profiles

- Work-Life Balance

- AI Essentials for Business

- Alternative Investments

- Business Analytics

- Business Strategy

- Business and Climate Change

- Design Thinking and Innovation

- Digital Marketing Strategy

- Disruptive Strategy

- Economics for Managers

- Entrepreneurship Essentials

- Financial Accounting

- Global Business

- Launching Tech Ventures

- Leadership Principles

- Leadership, Ethics, and Corporate Accountability

- Leading with Finance

- Management Essentials

- Negotiation Mastery

- Organizational Leadership

- Power and Influence for Positive Impact

- Strategy Execution

- Sustainable Business Strategy

- Sustainable Investing

- Winning with Digital Platforms

A Manager’s Guide to Successful Strategy Implementation

- 16 Jan 2024

To address business challenges and concerns, organizations must constantly monitor, evaluate, and adjust their strategic initiatives . When it’s time to implement a new strategy, it’s typically up to managers to do so.

Access your free e-book today.

What Is Strategy Implementation?

According to the online course Strategy Execution , strategy implementation is the process of turning plans into action to reach business goals and objectives . In other words, it’s the art of getting stuff done.

Your organization’s success rests on your ability to implement decisions and execute processes efficiently, effectively, and consistently. Yet, that’s often easier said than done.

“If you've looked at the news lately, you've probably seen stories of businesses with great strategies that have failed,” says Harvard Business School Professor Robert Simons, who teaches Strategy Execution . “In each, we find a business strategy that was well formulated but poorly executed.”

You can learn a lot from failed strategies , and understanding how to implement a successful one is vital to leading change. Here are steps you can take to effectively roll out your business strategy .

4 Steps in the Strategy Implementation Process

1. handle tension.

Making tough choices isn’t easy, and you need to manage any tension that arises with change.

In strategy implementation, tension often exists between innovating to grow your business and controlling internal processes and procedures.

For example, leaders at ride-hailing company Uber have faced challenges in balancing growth and control. While Uber has transformed the transportation industry, its need to expand has led to several instances of misconduct due to insufficient internal controls .

You can manage tension and find balance by designing and implementing levers of control , which comprise:

- Belief systems : Organizational definitions you communicate and reinforce to provide direction to employees

- Boundary systems : Negatively phrased statements that tell employees what behaviors are forbidden

- Diagnostic control systems : Formal information systems that help monitor organizational outcomes

- Interactive control systems : Formal systems managers use to involve themselves in subordinates' decisions that impact strategic uncertainties

These levers help create opposing forces throughout strategy implementation that continuously balance each other. While half of them (belief systems and interactive control systems) promote innovation and inspiration, the others (boundary systems and diagnostic control systems) establish boundaries and threats of punishment when employees cross the line.

To ensure your strategy execution succeeds , use the power of tension when designing management control systems.

2. Align Job Design to Strategy

No matter how well-formulated your business strategy is, it can’t succeed without your team. To prime employees for success, it’s essential to design jobs with strategy in mind.

Job design is structuring jobs’ components to enhance organizational efficiency. Its common elements include task allocation, job development, and feedback and communication.

“Job design is a critical part of strategy execution,” Simons says in Strategy Execution . “If individuals don't have the resources they need and aren’t accountable in the right way, they won’t be able to work to their potential.”

According to Simons, you can use the Job Design Optimization Tool (JDOT) to design or test jobs by analyzing their balance of demands and resources.

The tool prompts you to consider:

- What resources do employees have to get the job done?

- What measure will we use to evaluate their performance?

- Who must they influence to achieve their goals?

- How much support can they expect when reaching out for help?

By answering these questions and ensuring they align with your strategy, employees can directly support your initiatives.

3. Inspire Employee Buy-In

Even if you position employees for success through effective job design, you must still gain their buy-in for strategic goals . According to a Gallup survey , organizations with strong employee engagement experience 10 percent greater customer loyalty and 23 percent higher profitability.

You can garner their support by communicating your organization’s core values —its purpose that impacts what employees should do and how they should act.

According to Strategy Execution , effective core values possess two attributes:

- Inspiration: They make employees proud of where they work.

- Guidance: They ensure employees know whose interests to prioritize when making difficult decisions.

Communicating your organization’s core values doesn’t just help bolster support for strategic initiatives; it also provides employees with a purpose to improve performance and workplace accountability .

Another useful tool is ranking systems.

“Ranking systems—which are quite common in practice—have really good features that managers can use to stimulate performance,” says HBS Professor Susan Gallani in Strategy Execution .

Ranking systems provide clear measures—like leadership capabilities—for employees to determine their ownership in your business strategy. Gallani says establishing such measures helps eliminate unknowns that create anxiety.

“What the ranking system does—it takes that shock away,” Gallani says in Strategy Execution . “Everybody's compared at the same level, and that's good because it really highlights the individual contribution of different workers and points out who did better and who did worse.”

By implementing ranking systems, achievement-driven employees can be more likely to invest in your business strategy.

Related: How to Get Employee Buy-In to Execute Your Strategic Initiatives

4. Manage Risk

Even if you take these steps when implementing your business strategy, your initiatives can still fail.

“Competing successfully in any industry involves some level of risk,” Simons says in Strategy Execution . “But high-performing businesses with high-pressure cultures are especially vulnerable. As a manager, you need to know how and why these risks arise and how to avoid them.”

Engaging in risk management —the systematic process of identifying, assessing, and mitigating threats or uncertainties that can affect your organization—is crucial to long-term success.

Three types of pressures that make you vulnerable to risk are:

- Information management

Business risks aren’t always obvious, making it critical to identify unexpected events or conditions that could impede your organization’s business strategy .

“I think one of the challenges firms face is the ability to properly identify their risks,” says HBS Professor Eugene Soltes in Strategy Execution .

For example, the automotive industry heavily relies on semiconductors. However, due to an unexpected disruption in manufacturing priorities during the COVID-19 pandemic, companies had to navigate production during a semiconductor shortage .

By understanding your strategy’s vulnerabilities, you can prevent failures because of unanticipated events and protect your organization from challenges like increased market competition, evolving technologies, and shifting customer needs .

Learn How to Oversee Strategy Implementation

Implementing strategy successfully is challenging.

By taking an online strategy course , such as Strategy Execution , you can draw insights from real-world business examples and build the strategy execution skills and knowledge to achieve your organization’s objectives.

Do you want to improve your strategy implementation? Explore Strategy Execution —one of our online strategy courses —and download our free strategy e-book to take the first step toward doing so.

This post was updated and republished on January 16, 2024. It was originally published on February 25, 2020.

About the Author

- Contact sales

Start free trial

Operational Planning: How to Make an Operations Plan

The operations of your business can be defined as the sum of all the daily activities that you and your team execute to create products or services and engage with your customers, among other critical business functions. While organizing these moving parts might sound difficult, it can be easily done by writing a business operational plan. But before we learn how to make one, let’s first understand what’s the relationship between strategic and operational planning.

Operational Planning vs. Strategic Planning

Operational planning and strategic planning are complementary to each other. This is because strategic plans define the business strategy and the long-term goals for your organization, while operational plans define the steps required to achieve them.

What Is a Strategic Plan?

A strategic plan is a business document that describes the business goals of a company as well as the high-level actions that will be taken to achieve them over a time period of 1-3 years.

What Is an Operational Plan?

Operational plans map the daily, weekly or monthly business operations that’ll be executed by the department to complete the goals you’ve previously defined in your strategic plan. Operational plans go deeper into explaining your business operations as they explain roles and responsibilities, timelines and the scope of work.

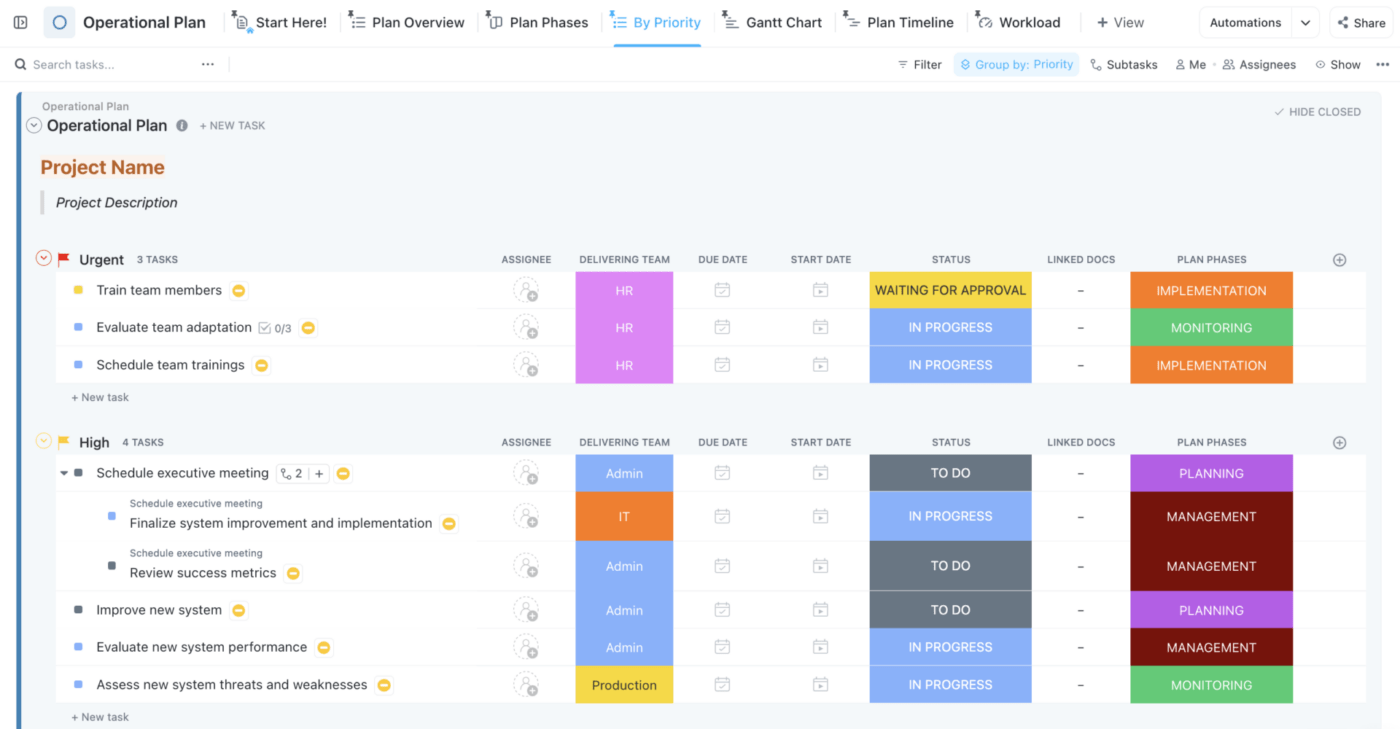

Operational plans work best when an entire department buys in, assigning due dates for tasks, measuring goals for success, reporting on issues and collaborating effectively. They work even better when there’s a platform like ProjectManager , which facilitates communication across departments to ensure that the machine is running smoothly as each team reaches its benchmark. Get started with ProjectManager for free today.

What Is Operational Planning?

Operational planning is the process of turning strategic plans into action plans, which simply means breaking down high-level strategic goals and activities into smaller, actionable steps. The main goal of operational planning is to coordinate different departments and layers of management to ensure the whole organization works towards the same objective, which is achieving the goals set forth in the strategic plan .

How to Make an Operational Plan

There’s no single approach to follow when making an operation plan for your business. However, there’s one golden rule in operations management : your strategic and operational plans must be aligned. Based on that principle, here are seven steps to make an operational plan.

- Map business processes and workflows: What steps need to be taken at the operations level to accomplish long-term strategic goals?

- Set operational-level goals: Describe what operational-level goals contribute to the achievement of larger strategic goals.

- Determine the operational timeline: Is there any time frame for the achievement of the operational plan?

- Define your resource requirements: Estimate what resources are needed for the execution of the operational plan.

- Estimate the operational budget: Based on your resource requirements, estimate costs and define an operational budget.

- Set a hiring plan: Are there any skills gaps that need to be filled in your organization?

- Set key performance indicators: Define metrics and performance tracking procedures to measure your team’s performance.

Get your free

Operational Plan Template

Use this free Operational Plan Template for Word to manage your projects better.

What Should be Included in an Operational Plan?

Your operational plan should describe your business operations as accurately as possible so that internal teams know how the company works and how they can help achieve the larger strategic objectives. Here’s a list of some of the key elements that you’ll need to consider when writing an operational plan.

Executive Summary

An executive summary is a brief document that summarizes the content of larger documents like business plans, strategic plans or operation plans. Their main purpose is to provide a quick overview for busy stakeholders.

Operational Budget

An operational budget is an estimation of the expected operating costs and revenues for a given time period. As with other types of budget, the operational budget defines the amount of money that’s available to acquire raw materials, equipment or anything else that’s needed for business operations.

It’s important to limit your spending to stay below your operational budget, otherwise, your company could run out of resources to execute its normal activities. You can use our free operating budget template for Excel to track your operating costs.

Operational Objectives

It’s essential to align your operational objectives with your strategic objectives. For example, if one of your strategic objectives is to increase sales by 25 percent over the next three years, one possible operational objective would be to hire new sales employees. You should always grab your strategic plan objectives and turn them into one or multiple action items .

Processes & Workflows

Explain the various business processes, workflows and tasks that need to be executed to achieve your operational objectives. Make sure to explain what resources are needed, such as raw materials, equipment or human resources.

Operational Timeline

It’s important to establish a timeline for your operational plan. In most cases, your operational plan will have the same length as your strategic plan, but in some scenarios, you might create multiple operational plans for specific purposes. Not all operational plans are equal, so the length of your operational timeline will depend on the duration of your projects , workflows and processes.

Hiring Plan

Find any skills gap there might be in your team. You might need to hire a couple of individuals or even create new departments in order to execute your business processes .

Quality Assurance and Control

Most companies implement quality assurance and control procedures for a variety of reasons such as customer safety and regulatory compliance. In addition, quality assurance issues can cost your business millions, so establishing quality management protocols is a key step in operational planning.

Key Performance Indicators

It’s important to establish key performance indicators (KPIs) to measure the productivity of your business operations. You can define as many KPIs as needed for all your business processes. For example, you can define KPIs for marketing, sales, product development and other key departments in your company. This can include product launch deadlines, number of manufactured goods, number of customer service cases closed, number of 5-star reviews received, number of customers acquired, revenue increased by a certain percentage and so on.

Risks, Assumptions and Constraints

Note any potential risks, assumptions and time or resource constraints that might affect your business operations.

Free Operational Plan Template

Leverage everything you’ve learned today with our template. This free operational plan template for Word will help you define your budget, timeline, KPIs and more. It’s the perfect first step in organizing and improving your operations. Download it today.

What Are the Benefits of Operational Planning?

Every plan has a massive effect on all team members involved, and those can be to your company’s benefit or to their detriment. If it’s to their detriment, it’s best to find out as soon as possible so you can modify your operational plan and pivot with ease.

But that’s the whole point of operational planning: you get to see the effect of your operations on the business’s bottom line in real time, or at every benchmark, so you know exactly when to pivot. And with a plan that’s as custom to each department as an operational plan, you know exactly where things go wrong and why.

How ProjectManager Can Help with Operational Planning

Creating and implementing a high-quality operational plan is the best way to ensure that your organization starts out a project on the right foot. ProjectManager has award-winning project management tools to help you craft and execute such a plan.

Gantt charts are essential to create and monitor operational plans effectively. ProjectManager helps you access your Gantt chart online so you can add benchmarks for operational performance reviews. You can also create tasks along with dependencies to make the operation a surefire success.

Whether you’re a team of IT system administrators, marketing experts, or engineers, ProjectManager includes robust planning and reporting tools. Plan in sprints, assign due dates, collaborate with team members and track everything with just the click of a button. Plus, we have numerous ready-made project reports that can be generated instantly, including status reports, variance reports, timesheet reports and more.

Related Operations Management Content

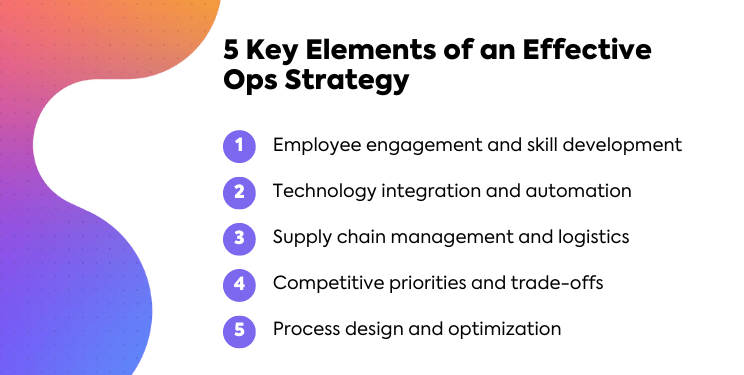

- Operational Strategy: A Quick Guide

- Operations Management: Key Functions, Roles and Skills

- Operational Efficiency: A Quick Guide

- Using Operational Excellence to Be More Productive

Operational planning isn’t done in a silo, and it doesn’t work without the full weight of the team backing it up. Ensure that your department is successful at each benchmark. ProjectManager is an award-winning pm software dedicated to helping businesses smooth out their operational plans for a better year ahead. Sign up for our free 30-day trial today.

Deliver your projects on time and under budget

Start planning your projects.

- Search Search Please fill out this field.

What Is Operations Management (OM)?

Understanding operations management (om), operations and supply chain management (oscm), what operations managers do.

- Frequently Asked Questions

The Bottom Line

- Business Essentials

Operations Management: Understanding and Using It

Adam Hayes, Ph.D., CFA, is a financial writer with 15+ years Wall Street experience as a derivatives trader. Besides his extensive derivative trading expertise, Adam is an expert in economics and behavioral finance. Adam received his master's in economics from The New School for Social Research and his Ph.D. from the University of Wisconsin-Madison in sociology. He is a CFA charterholder as well as holding FINRA Series 7, 55 & 63 licenses. He currently researches and teaches economic sociology and the social studies of finance at the Hebrew University in Jerusalem.

:max_bytes(150000):strip_icc():format(webp)/adam_hayes-5bfc262a46e0fb005118b414.jpg)

Operations management (OM) is the administration of business practices to create the highest level of efficiency possible within an organization. It is concerned with converting materials and labor into goods and services as efficiently as possible to maximize the profit of an organization.

Operations management teams attempt to balance costs with revenue to achieve the highest net operating profit possible.

Key Takeaways

- Operations management (OM) is the administration of business practices to create the highest level of efficiency possible within an organization.

- Operations management is concerned with converting materials and labor into goods and services as efficiently as possible.

- Corporate operations management professionals try to balance costs with revenue to maximize net operating profit.

Katie Kerpel / Investopedia

Operations management involves utilizing resources from staff, materials, equipment, and technology. Operations managers acquire, develop, and deliver goods to clients based on client needs and the abilities of the company.

Operations management handles various strategic issues, including determining the size of manufacturing plants and project management methods and implementing the structure of information technology networks. Other operational issues include the management of inventory levels, including work-in-process levels and raw materials acquisition, quality control, materials handling, and maintenance policies.

Operations management entails studying the use of raw materials and ensuring that minimal waste occurs. Operations managers use numerous formulas, such as the economic order quantity formula, to determine when and how large an inventory order to process and how much inventory to hold on hand.

The combination of understanding and coordinating the work of a company is central to becoming a successful operations manager.

A critical function of operations management relates to the management of inventory through the supply chain. This process is known as operations and supply chain management (OSCM). To be an effective operations management professional, one must be able to understand the processes that are essential to what a company does and get them to flow and work together seamlessly. The coordination involved in setting up business processes in an efficient way requires a solid understanding of logistics .

An operations management professional understands local and global trends, customer demand, and available resources for production. Operations management approaches the acquisition of materials and the use of labor in a timely, cost-effective manner to deliver customer expectations. Inventory levels are monitored to ensure that excessive quantities are on hand. Operations management is responsible for finding vendors that supply the appropriate goods at reasonable prices and have the ability to deliver the product when needed.

Another large facet of operations management involves the delivery of goods to customers. This includes ensuring that products are delivered within the agreed time commitment. Operations management also typically follows up with customers to ensure that the products meet quality and functionality needs. Finally, operations management takes the feedback received and distributes the relevant information to each department to use in process improvement.

Operations managers are involved in coordinating and developing new processes while reevaluating current structures. Organization and productivity are two key drivers of being an operations manager, and the work often requires versatility and innovation. As part of their daily responsibilities, operations managers must possess a variety of skill sets, including:

- Technical expertise in areas such as production automation, data entry, budget tracking, and design.

- Organizational ability and attention to detail to include keeping track of project files, employee reports, budgets, schedules, and other details related to company processes.

- Motivational prowess in the form of strong leadership skills that provide the expertise to motivate others, inspire ideas, and foster a supportive and diverse team.

- Analytical aptitude , including skill in risk analysis and mitigation when initiating new projects. Operations managers also must analyze processes to identify challenges and offer solutions in the event that negative situations develop.

- Decision-making proficiency , especially under stress when there is very little time to assess all factors.

- Ability to maintain quality standards , including as they relate to raw materials, machinery, manufacturing procedures, packaging, delivery processes, and the finished product.

A master of business administration (MBA) degree in operations management can provide global perspective on industry trends and an awareness of financial regulations and political uncertainties that can affect an organization. It also provides a solid grasp of the inherent complexities and the tools needed to respond well to change.

What is the purpose of operations management (OM)?

Operations management (OM) is concerned with controlling the production process and business operations in the most efficient manner possible. OM professionals attempt to balance operating costs with revenue to maximize net operating profit.

What are some systems of operations management?

Modern operations management revolves around four theories:

- Business process redesign (BPR) , which is focused on analyzing and designing workflow and business processes within a company. The goal of BPR is to help companies dramatically restructure the organization by designing the business process from the ground up.

- Reconfigurable manufacturing systems , designed to incorporate accelerated change in structure, hardware, and software components. This allows systems to adjust rapidly to the capacity to which they can continue production and how efficiently they function in response to market or intrinsic system changes.

- Six Sigma , an approach that focuses on quality. The word “six” references the control limits, which are placed at six standard deviations from the normal distribution mean. Tools used within the Six Sigma process include trending charts, potential defect calculations, and other ratios.

- Lean manufacturing , which is the systematic elimination of waste within the manufacturing process. This theory sees resource use for any reason other than value creation for customers as wasteful and seeks to eliminate wasteful resource expenditures as much as possible.

What is an example of operations management?

Operations management is prevalent in the healthcare sector . The current healthcare system overuses expensive, technological, and emergency-based treatment. High costs from care often remain uncompensated due to uninsured patients. A prevalence of services in expensive settings creates a burden on taxpayers, health insurance holders, and healthcare institutions.

In simple terms, operations management (OM) is the process of prioritizing and employing business practices designed to achieve maximum efficiency as a means to achieve maximum profitability. Within the process, operations managers utilize organization and productivity to achieve their primary goals.

Balancing the efficient use of resources, including staff, materials, equipment, and technology, is key to a successful OM process and, by extension, to the success of the company.

University at Buffalo, School of Management. “ Operations and Supply Chain Management .”

Indeed. “ 15 Essential Operational Management Skills .”

:max_bytes(150000):strip_icc():format(webp)/scm.asp-ADD-SOURCE-73001143e596430091d315486bcd6792.png)

- Terms of Service

- Editorial Policy

- Privacy Policy

- Your Privacy Choices

Operational Plan: Everything You Need To Know (2024 Guide)

The old way of planning no longer works in complex and unpredictable business environments, and companies are struggling to find their feet on shaky ground. As we’ve seen with many of our customers and strategies in Cascade, organizations can no longer count on executing three or even five-year strategic plans.

The new reality forces companies and their operations teams to adapt their operational plans more frequently and within shorter time frames if they want to reap benefits faster than their competitors. Organizations need to work on their strategic instinct and fast adaptability to enhance their operational efficiency .

And that requires big changes—including building a flexible operational plan, supported by the right tools and systems that help you achieve real-time centralized observability and empower a strategic response to external disruptions.

Read this article to build a bulletproof operational plan that includes all the key elements necessary to overcome unpredictable business chaos. You’ll also get free templates that will help you rapidly adapt and align your teams.

✨Bonus: We’ve included pro tips from business leaders in our network to help you identify gaps in your strategy execution and build resilient business operations.

What Is An Operational Plan?

An operational plan is action and detail-oriented; it needs to focus on short-term strategy execution and outline an organization's day-to-day operations. If your operations strategy is a promise, your operational plan is the action plan for how you will deliver on it every day, week, and month.

Put simply, an operational plan helps you bridge the gap between business strategy and on-the-ground execution and ensures that the organization is on track to achieve its long-term goals.

Benefits of operational planning

- Clear definition of relationships between cross-functional teams in different departments and responsibilities for each to eliminate duplicated efforts.

- Tighter alignment between corporate or business unit strategic plans and on-the-ground execution, helping the organization meet its business targets.

- Strong operating system that enables the company to quickly adapt, deliver operations goals, and monitor performance.

Operational planning vs. strategic planning

Operational planning deals with the day-to-day details and short-term goals, while strategic planning focuses on the big picture and long-term direction of an organization.

To put it in simpler terms, operational planning is about the "how" of daily tasks, while strategic planning defines the "what" and "why" for future success.

📚Recommended reading: Strategic vs. Operational Planning

Kickstart Your Operational Planning Process: Lay The Foundation

The quality of your operational plan will depend on your input. A successful operational planning initiative will consider these aspects:

- Who will be involved? Identify and include employees, customers, and the management team in the planning process to gain valuable insights from the front lines, ensuring better strategy and execution buy-in.

- What are your internal capabilities? Assess internal capabilities by conducting an internal analysis , including resource requirements, operating budget, and talent skills. Talent management and employee engagement are just a few of the many challenges that COOs will have on their operations agenda.

- What environment are you operating in? Conduct an external analysis (e.g., PESTLE or Porter’s 5 Forces ) to inform your approach and identify optimization opportunities and risks, keeping you agile in a changing market.

- Is it aligned with your organization’s strategy? Ensure alignment of your operational plan with your organization’s strategic plan to actively support the company's long-term vision and contribute to key business metrics.

👉🏻 Once you’ve gathered this information, you can develop an operational plan to help you execute business strategies.

Key Elements Of Your Operational Plan

Enough chit-chat; it’s time to put your operational plan together. We've built this based on our proven and tested approach, used by over +45,000 Cascade users.

See how Cascade Strategy Execution Platform enhances operational efficiency by reducing duplication and aligning teams toward common goals. It effectively eliminates waste resulting from misalignment, fostering smoother operations and improved performance.

Here’s a recap of the five key elements your plan must consider:

Choose key metrics aligned with the company goals

Selecting your operational plan's key metrics isn't a mere exercise in tracking numbers; it's about laser-focused alignment with your business needs and objectives. These metrics are the tangible indicators of your organization's efficiency and performance. They serve as the compass, guiding your daily decisions and actions toward achieving concrete results.

By precisely aligning these metrics with your company's core objectives, you ensure that every initiative and action within your operational plan directly contributes to achieving tangible results.

An aligned operational plan makes it easier to:

- Communicate roles and responsibilities to all employees so they know how their efforts contribute to overall business success.

- Identify and address operational bottlenecks and inefficiencies that could derail strategy execution.

- Motivate and engage employees to work toward strategic objectives and deliver on business outcomes.

Remember that the role of operations is to close the gap between your organization's strategic goals and what is being done on a daily basis to make them happen.

👉🏻 How Cascade can help:

With Cascade’s Metrics Library , you can bring your operating and financial business-level goals together with your strategy under one single roof. This makes reporting & governance easy, accurate, and less time-consuming by connecting your business data to your key business initiatives.

.png)

Through Cascade’s integrations , you can consolidate your metrics in one place, importing your data directly from business systems, data lakes, BI tools, or even spreadsheets.

Define the focus areas of your operational plan

The focus areas of your operational plan are the key areas of the business that the plan will address.

This will depend on your business plan. Think about how the business operates and how it succeeds. Do you need to pursue short-term cost reductions while simultaneously pursuing longer-term growth and transformation initiatives? Your operational plans must be built on these strategic priorities.

For example, you can prioritize your focus areas based on the most relevant business strategies or by specific departments. Some examples of focus areas could be:

- Administration

- Human Resources

💡Tips to help define the focus areas of your operational plan:

- Identify the business's key challenges and opportunities.

- Consider the business's overall long-term strategy and key metrics and how the operational plan's focus areas can support these objectives.

- Bring other people on board to help you identify what needs to be addressed by the operations plan.

Create strategic objectives for your operational plan

Strategic objectives are specific goals aligned with the operation’s strategy and focus areas. They represent what you want to achieve in each focus area and will serve as the building blocks of your plan, ensuring that it’s focused and actionable.

Some examples of strategic objectives:

- Reduce costs by 10% within the next year by implementing more efficient processes and streamlining the supply chain over the next year.

- Launch three new products in the next fiscal year to expand your product lines and increase revenue.

- Increase customer satisfaction scores by 5% within the next six months.

💡Tips for defining strategic objectives include:

- Ensure your objectives are specific, measurable, achievable, relevant, and time-bound (SMART).

- Consistently align objectives with your operational plan's focus areas and the company's goals.

- Don’t be afraid to get input from other people about your objectives.

Identify and prioritize projects

It’s time to identify and prioritize the projects that need to be executed. Remember, projects are action plans to help you achieve your strategic objectives.

Project planning should include thinking about time frames, task assignments, and deliverables (and prioritizing).

Here are some examples of project ideas:

- Localize sourcing for critical semi-finished materials.

- Streamline the supply chain to reduce costs and improve efficiency.

- Find and develop an alternative logistics channel.

- Implement a new customer service training program to improve customer satisfaction scores.

- Implement a new technology that will enable end-to-end supply chain visibility.

💡Tips for defining and prioritizing projects:

- Identify the specific actions and activities needed to achieve each strategic objective.

- Prioritize the projects based on their importance, feasibility, and potential impact on the business.

- Involve stakeholders in defining and prioritizing the projects to ensure their needs and concerns are heard.

Identify and track key performance indicators (KPIs)

Finally, you’ll need to know if your operational plan and day-to-day activities result in outcomes.

Set KPIs for key initiatives and strategic objectives to measure success, ensure alignment, and identify performance gaps in your operational plan.

Some examples of operations KPIs are:

- Inventory costs

- Costs of goods sold

- Revenue growth

- Employee retention rate

- Customer satisfaction score

💡Tips for defining and tracking KPIs:

- Align KPIs with your strategic objectives and focus areas so that you can track the plan's progress against these specific goals.

- Add both lagging and leading indicators .

- Instead of using multiple disconnected spreadsheets and project management tools, consider live dashboards or reporting systems to track the KPIs and monitor progress over time.

👉🏻 How Cascade can help build your plan:

Cascade’s planner feature enables you to build your operational plan with structure and ease by breaking down the complexity from high-level initiatives to executable outcomes. Define your key elements (focus areas, objectives, projects, and KPIs), and share the plan with your teams. You’ll get full visibility of the plan’s progress in real-time, allowing you to identify gaps, quickly update the plan, and communicate the change with your team with a single click.

%20(1).png)

👉🏻 If you don’t want to start building the plan from scratch, use our free Operational Plan Template pre-filled with examples of focus areas, objectives, projects, and KPIs that you can customize to meet your organization’s needs.

Operational Plan Examples & Templates

Here are five operational plan examples to help you create plans for your teams. You can use one master operational plan or set up an operational plan for each department.

Master Operational Plan Example

.png)

This Operational Plan Template will help you close the gap between business goals and day-to-day operations. You'll be able to set goals and KPIs for your top priorities and work with the operations team to deliver operational excellence and business results.

HR Plan Example

This HR Operational Plan Template can be used to meet staffing requirements, manage human capital and align human resources activities with your strategy. HR managers in any industry can create a clear operational plan that can be constantly monitored, adapted, and improved.

IT Plan Example

If you’re in the IT team, try out this IT Plan Template to get your IT operational planning up and running fast. It comes prefilled with focus areas and KPIs relevant to IT operations; you can easily customize workflows and deliverables to your needs.

Marketing Plan Example

This Marketing Plan Template can help you efficiently understand and plan your digital marketing operations using best practices. Use it to quickly set up priorities and get your social media and marketing teams moving on tasks that will make an impact.

Finance Plan Example

This finance-focused template is ideal if you want to get on top of your finance operations plan. Use it to allocate and distribute financial resources across your organization and get real-time updates through your dashboard and reports—which are great tools to create a visually compelling financial summary that clearly shows your key metrics.

💡Pro Tip: To ensure successful execution, it's crucial to align not just your master operational plan with your overarching strategic plan, but also all the operational department plans.

With the Alignment Maps feature, you’ll be able to visualize how your top-level business strategy breaks down into functional and operational plans. This empowers COOs and CFOs to consolidate their operational plans in one place, creating tighter alignment between the finance and operations teams and improving cross-collaboration to build more resilient operations.

Want to dig deeper? Use the Relationships feature to see the relationships between connected objectives from your plans and understand how your different department goals contribute to the core business metrics and goals. This view will allow you to clearly map dependencies, blockers, and risks that may lie along your journey.

%20(1).png)

5 Tips For An Effective Operational Plan And Its Execution

1. don’t underestimate the power of transparent communication.

Regularly communicate the operational plan and progress to all relevant stakeholders to build the necessary buy-in and support. Your employees must know your goals and the roadmap, and team members should understand their role in its execution. This business transparency will help everyone row in the same direction.

“Clarity regarding strategy is one of the key drivers of autonomous execution. If people understand what you’re working toward and have guardrails in place, they can be empowered to make their own decisions and don’t need everything to be ‘run up the chain’ to get approved. This allows you to move fast and at scale.” — Sam Sterling , Chief Strategy Officer, Akqa

2. Keep moving forward and adopt a growth mindset

Keep the momentum going and ensure that the plan is executed effectively. Regular monitoring and reviews can help identify and address any challenges or obstacles that may arise.

Schedule regular reviews and check-ins and provide the necessary support to ensure projects are on track and moving forward.

“I think adopting a growth mindset is super important. This means having the confidence to fail fast, try something new and empower people to do that.” — Ken Miller , General Manager, Azure Intelligent Cloud at Microsoft

With the Team Updates functionality, every team member can post updates on key measures, actions, and objectives. This will give you real-time visibility into performance and help you identify possible risks before it’s too late—without having to schedule extra meetings or nag your team members for updates.

3. Make strategic moves and change fast when you need to

Your operational plan should be flexible, adaptable, and open to adjustments. This means keeping an eye on progress, making corrections if needed, and being willing to adapt the plan to changing circumstances or new opportunities. As McKinsey suggests, you can consider creating a team that will be able to collect data, link analysis with action, and offer quick responses to rapid changes.

“Traditionally, companies would have taken that piece of paper and gone out and said: we're going to execute it, start to finish. Then get into the formulation of the strategy, what we need to hit, and what the end product result will be like. But what we do know is that’s never the case. Along the way, you're going to have bumps, and inevitably, you’ll need to change from that original picture.” — Annie Lucchitti , Marketing Manager, Unilever

4. Empower your operations team and boost efficiency

Effective operational planning requires the engagement and empowerment of your team. Involve stakeholders in the planning process and provide them with the necessary resources. Give them context and an opportunity to set goals and prioritize initiatives. This will help you boost engagement and hold them accountable for progress.

“I think it just works at every single level. Are people allowed to be themselves at work? Personally, are they at peace? Are they happy? Productivity happens when people have the right skills, but also when they are engaged and happy. If one of those fails a bit, productivity will start decreasing.” — Joan Torrents , Global Sourcing Manager, TESCO.

5. If it isn’t measured, it isn’t managed

Don’t underestimate the importance of tracking and measuring progress against the operational plan's goals and objectives. Set milestones, enforce KPIs, and stay on top of progress. Doing this will help you stay on course, empower you to act quickly, and provide valuable insights into what is going wrong.

“Data is a foundational element in the strategy definition phase as well as in the strategy execution phase as it helps create a baseline, identify key priorities, set goals, and measure progress.” — Erica Santoni , Principal, Diversity Equity & Inclusion, Intuit

Use Cascade’s Dashboards to monitor your day-to-day progress on key metrics and critical business and strategic information in real-time.

.jpg)

Compile the information in powerful reports and executive summaries in seconds with pre-built templates. Share them with your key stakeholders —internal and external— and invite them to collaborate on your strategy together.

Execute Your Operational Plan With Cascade 🚀

What good is an operational plan if no one executes it? If your organization wants to operate at a higher level, static tools like Excel spreadsheets, PowerPoints, Google Docs, and/or project management tools aren’t the solution.

❌They aren’t designed for adaptive strategy and planning.

❌They often lead to siloing and hinder effective cross-collaboration.

❌They make it challenging to measure progress and slow down decision-making.

With Cascade as your central operating system, you can stop running business operations blindfolded and embrace rapid, coordinated, and data-driven decision-making.

Get your Operational Plan Template to get started with a dynamic plan that will lead to actual outcomes for your business and see faster results from your strategy.

Or take Cascade for a spin! Start today for free or book a 1:1 product tour with Cascade’s in-house strategy expert.

Popular articles

Viva Goals Vs. Cascade: Goal Management Vs. Strategy Execution

What Is A Maturity Model? Overview, Examples + Free Assessment

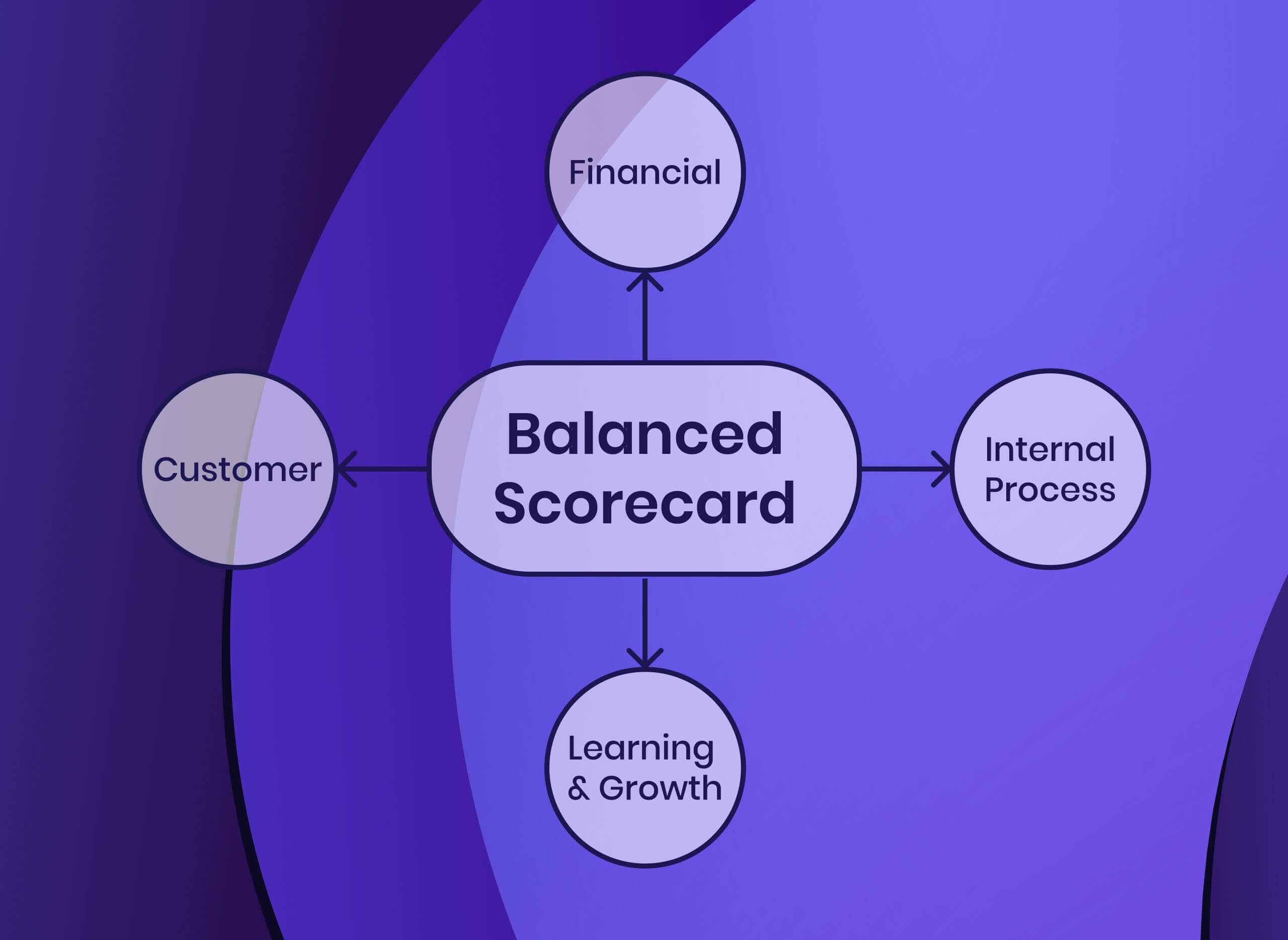

How To Implement The Balanced Scorecard Framework (With Examples)

The Best Management Reporting Software For Strategy Officers (2024 Guide)

Your toolkit for strategy success.

- Professional Services

- Creative & Design

- See all teams

- Project Management

- Workflow Management

- Task Management

- Resource Management

- See all use cases

Apps & Integrations

- Microsoft Teams

- See all integrations

Explore Wrike

- Book a Demo

- Take a Product Tour

- Start With Templates

- Customer Stories

- ROI Calculator

- Find a Reseller

- Mobile & Desktop Apps

- Cross-Tagging

- Kanban Boards

- Project Resource Planning

- Gantt Charts

- Custom Item Types

- Dynamic Request Forms

- Integrations

- See all features

Learn and connect

- Resource Hub

- Educational Guides

Become Wrike Pro

- Submit A Ticket

- Help Center

- Premium Support

- Community Topics

- Training Courses

- Facilitated Services

Exploring Operations Control Systems for Enhanced Efficiency

September 2, 2023 - 10 min read

In today's rapidly changing business landscape, organizations are continuously seeking ways to improve their efficiency and maximize their productivity. One area that plays a crucial role in achieving these goals is operations control systems. In this article, we will delve into the world of operations control systems, understanding their role in business, their key components, how they enhance efficiency, and the steps involved in implementing them. We will also explore future trends in this field, examining the impact of technology and predicted developments.

Understanding Operations Control Systems

Operations control systems serve as the backbone of any organization, playing a pivotal role in managing and coordinating various aspects of its operations. These systems provide a centralized platform that enables businesses to monitor and control their processes, resources, and tasks efficiently.

The Role of Operations Control Systems in Business

Operations control systems play a vital role in driving business success. They enable companies to effectively manage their resources, minimize operational risks, and improve overall productivity. These systems also facilitate effective decision-making by providing accurate and timely information. With access to comprehensive data and analytics, businesses can make informed decisions that align with their strategic goals and objectives. This enables them to stay ahead of the competition and adapt to changing market dynamics. Lastly, operations control systems foster better collaboration and communication. By providing a centralized platform for task management and coordination, these systems guarantee that employees have a clear understanding of their responsibilities and can collaborate seamlessly.

Key Components of Operations Control Systems

An operations control system typically consists of several key components that work together to enable effective management of operations:

- Data Collection and Monitoring Module: Involves the collection of data from various sources, such as sensors, machines, and software applications, and the continuous monitoring of operational metrics. Companies can utilize this module to gather real-time data on key performance indicators (KPIs) such as production output, quality metrics, and resource utilization. This data provides insights into the current state of operations, allowing businesses to identify potential issues or deviations from desired performance levels.

- Analytics and Reporting Module: Leverages advanced analytical techniques to process the collected data, identify patterns and trends, and generate meaningful insights. Through detailed reports and visualizations, businesses can gain a comprehensive understanding of their operations, identify areas for improvement, and track their progress over time. For example, they can perform in-depth analysis of their operations, such as root cause analysis, predictive modeling, and trend forecasting.

- Task Management Module: Facilitates the planning, allocation, and tracking of tasks. This provides a centralized platform for employees to access and manage their tasks, and they can set deadlines and track their own progress. What's more, this module improves communication and collaboration among team members. It provides a platform for sharing updates, exchanging information, and seeking assistance, fostering a culture of teamwork and cooperation.

How Operations Control Systems Improve Workflow

Operations control systems enhance efficiency by optimizing workflow. By automating manual processes, eliminating bottlenecks, and improving communication and coordination among different departments, these systems ensure that work is streamlined and flows smoothly across the organization. This leads to faster turnaround times, reduced errors, and improved overall productivity.

Let's consider a manufacturing company that implements an operations control system. This system automates the process of tracking inventory levels, production schedules, and order fulfillment. Integrating these different aspects of the manufacturing process signifies that materials are available when needed, production is scheduled efficiently, and orders are fulfilled in a timely manner. As a result, the company experiences improved workflow, reduced lead times, and increased customer satisfaction.

Reducing Waste with Operations Control Systems

Operations control systems also possess the ability to identify and eliminate waste in various forms. These systems can help businesses identify unnecessary steps, reduce wait times, minimize excess inventory, and streamline their supply chain. They can even identify and address quality issues, which can help companies quickly implement the appropriate corrective action.

Picture a retail company that implements an operations control system. Through data analysis, the system identifies that a significant amount of waste is generated due to overstocking of certain products. With this insight, the company can adjust its inventory management practices, so that stock levels are aligned with customer demand. As a result, the company reduces waste, avoids unnecessary costs, and creates a more sustainable business model.

Implementing Operations Control Systems for Enhanced Efficiency

The implementation of an operations control system requires careful planning and execution. For a successful implementation, follow these key steps.

- Clearly define the objectives and identify the specific areas of the operations where efficiency needs to be improved. For example, a manufacturing firm may want to streamline their production process to reduce waste and increase productivity.

- Assess the existing processes and systems to identify any gaps or areas for improvement. Analyze data, conduct process mapping exercises, and gather feedback from stakeholders. For instance, a logistics company may realize that their current inventory management system is causing delays and errors in their supply chain. They conduct a thorough assessment to flag the specific areas that need improvement.

- Select an appropriate operations control system that aligns with their requirements. The chosen system must integrate seamlessly with the existing technology infrastructure, be scalable, and easy to use. For instance, a retail business may choose to implement a cloud-based operations control system that can easily integrate with their existing point-of-sale system and inventory management software. The new system can effectively track sales, manage inventory, and provide real-time data for decision-making.

- Develop an implementation plan, including timelines, resource allocation , communication strategies, training, and change management initiatives. For example, a healthcare organization implementing a new operations control system for patient scheduling may need to provide training to staff members on how to use the system effectively. They may also need to communicate the benefits of the system to patients as well.

- Regularly review and evaluate the performance of the operations control system, and seek feedback from employees and stakeholders. For instance, a hospitality company implementing an operations control system for managing hotel bookings may regularly review customer feedback and monitor key performance indicators. They can then make necessary adjustments and enhancements to continuously improve efficiency and customer satisfaction.

Overcoming Challenges in Operations Control System Implementation

While implementing an operations control system can yield significant benefits, organizations may encounter challenges along the way. Some common challenges include resistance to change, data integration issues, and the need for skilled resources.

- Resistance to change: A financial institution implementing an operations control system for fraud detection may face resistance from employees who are accustomed to manual processes. By clearly communicating the benefits of the system, such as increased accuracy and efficiency, and involving employees in the decision-making process, the organization can address resistance and gain buy-in from the staff.

- Data integration issues: A telecommunications company implementing an operations control system for network monitoring may need to work closely with their network equipment vendors and IT teams to verify that the system can effectively collect and analyze data from various network devices.

- Need for skilled resources: A transportation company implementing an operations control system for route optimization may need to provide training to their logistics team on how to effectively use the system and interpret the data it provides. This guarantees that they can fully leverage the capabilities of the system and achieve the desired efficiency improvements.

Future Trends in Operations Control Systems

As the pace of technological advancements accelerates, operations control systems are poised to undergo significant transformations. With the advent of Internet of Things (IoT) devices, artificial intelligence, and big data analytics, these systems will become increasingly sophisticated and capable of handling vast amounts of data in real-time.

Furthermore, emerging technologies such as machine learning and predictive analytics will enable operations control systems to anticipate issues, automate decision-making processes, and optimize operations proactively. This will result in even greater efficiency gains and improved business outcomes.

Predicted Developments in Operations Control Systems

In the near future, operations control systems are likely to become more interconnected and integrated with other systems within organizations. This integration will enable seamless data sharing and collaboration, resulting in a more holistic approach to managing operations.

Additionally, the use of mobile devices for accessing and controlling operations control systems is expected to become more prevalent. This will provide businesses and employees with greater flexibility and accessibility, allowing them to monitor and manage their operations on the go. Lastly, the integration of operations control systems with advanced technologies such as blockchain will enhance the security and transparency of data, increasing trust and facilitating more efficient supply chain management.

Explore Operations Control Systems with Wrike

Operations control systems can enhance efficiency. With Wrike, you can explore and implement effective operations control systems. Wrike allows you to create individual folders for each control system initiative, serving as a central hub for all relevant information and updates. Beyond just exploring operations control systems, Wrike offers a comprehensive suite of tools designed to streamline your workflows, foster collaboration, and drive productivity. From real-time communication to intuitive task management features, Wrike provides everything you need to explore operations control systems for enhanced efficiency. Ready to explore operations control systems and boost your efficiency? There's no better time to start than now. Get started with Wrike for free today.

Note: This article was created with the assistance of an AI engine. It has been reviewed and revised by our team of experts to ensure accuracy and quality.

Occasionally we write blog posts where multiple people contribute. Since our idea of having a gladiator arena where contributors would fight to the death to win total authorship wasn’t approved by HR, this was the compromise.

Related articles

Dark Matter of Work: The Cost of Work Complexities in The PMO

Efficiency is everything for organizations – especially as we face a possible recession and mass layoffs continue. Plus, the way we work continues to evolve and become more complex, causing efficiency to suffer even more. Over the past few years, modern work complexities have been eating away at your bottom line through an invisible yet powerful presence in your organization — what we call the Dark Matter of Work. Just as CERN identified Dark Matter as the “invisible” content that makes up 95% of the mass of the universe, the Dark Matter of Work represents activity and details that we can’t immediately see but that have a significant influence on everything around it. From the tools we use to conduct our work to where and when we execute it, work complexities have truly exploded in recent years and will only become more complicated over time — making it increasingly difficult for employees and business leaders to get visibility into work and truly understand work in progress. Wrike is focused on shining a light on the Dark Matter of Work. That’s why we recently commissioned research to investigate its impact on PMO leaders, employees, and organizations as a whole. We wanted to understand to what extent Dark Matter exists and discover the financial cost of Dark Matter affecting us all. The results are staggering and can point PMOs towards key ways they can increase efficiency to endure the unknown economic future. Let’s explore the results. Impact on the PMO While we cannot “see” the Dark Matter of Work, we can identify where it exists. It lives in synchronous applications and unstructured work, such as instant message threads and video calls, as well as the gaps between systems and applications that aren’t integrated. Without a single work platform that is powerful and versatile enough to track, manage, action, and align all work to goals across an organization, there exists a dangerously low level of visibility amongst knowledge workers and leaders. At present, most project managers and PMO leaders generally have little visibility into the work their teams are doing and cannot track the progress of much of that work in real time. And if we ask knowledge workers, they say employer visibility into their work is even lower — suggesting there may be more Dark Matter of Work than we think. Wasted time Time wasted on activities such as repeating work that’s already been done, attending unproductive meetings, or following up on actions and statuses costs the average enterprise millions. The cost of the Dark Matter of Work The total cost of Dark Matter for PMOs and project managers is quite substantial and will continue to increase exponentially unless addressed. Low visibility For business and PMO leaders, visibility into work has only increased slightly since 2020 — from 48% to 51%. And other project managers are struggling to view their assignments and expectations. More human costs Amid the Great Resignation, the mass layoffs, and the continuing remote work environment, PMOs must work to address the human costs of the Dark Matter of Work, as well. Too many applications As hybrid work continues, PMOs rely more and more on applications to stay connected. But many of these tech tools do not integrate with each other, decreasing visibility, increasing wasted time, and resulting in duplicative work. Plus, app integration is also moving at a slow pace from 2020 (43%) to now (49%). Looking ahead If left unchecked, Dark Matter will increase by 42% in the next five years. According to the survey, the projected cost of Dark Matter in 2027 looks to be: How can you minimize these costs? A single source of truth is essential. PMOs need a solution that is robust enough to manage and orchestrate complex workflows and simple enough for team members to use. The organization with full visibility into these workflows and applications and the data they create at all levels will be best equipped to overcome the impacts of the Dark Matter of Work and come out on top. For more on the Dark Matter of Work, its costs, and the solutions, check out the full report here — and usher in a new age of digital collaboration. Or start a free two-week trial of Wrike today to see how our work management solution can centralize work and increase efficiency for your PMO!

Scrum Master vs. Project Manager: Key Differences