Maintenance work is planned for Wednesday 1st May 2024 from 9:00am to 11:00am (BST).

During this time, the performance of our website may be affected - searches may run slowly and some pages may be temporarily unavailable. If this happens, please try refreshing your web browser or try waiting two to three minutes before trying again.

We apologise for any inconvenience this might cause and thank you for your patience.

Themed collection Crystal Growth

Spin crossover crystalline materials engineered via single-crystal-to-single-crystal transformations.

This highlight illustrates the latest crystalline materials engineered via SCSC transformations, with emphasis on the onset and progress of spin crossover in a crystal control.

Progress in controlling the synthesis of atomically precise silver nanoclusters

This short review was designed to summarize the advances in synthesis methods of silver nanoclusters.

Epitaxial nanotwinned metals and alloys: synthesis-twin structure–property relations

Recent works of epitaxial nanotwinned metals and alloys with different stacking fault energies are reviewed to elaborate the relationship among synthesis conditions, intrinsic factors, twin structure and various properties.

Sublimation – a green route to new solid-state forms

Sublimation is an effective and ‘green’ method to prepare and identify new polymorphs, cocrystals, ionic cocrystals and molecular salts.

Electrochemically induced nucleation of oxidic crystals in melts – a review

Electrochemically induced nucleation refers to a method where an applied potential triggers an electrochemical reaction which changes the conditions in the melt so that nucleation can occur where it was previously not significantly possible.

Review on quasi-2D square planar nickelates

Quasi-2D square planar nickelates exhibit key ingredients of high- T c superconducting cuprates. Whether bulk samples are superconducting remains an open question, single crystals are ideal platforms for addressing such fundamental questions.

Micro-pulling-down growth of long YAG- and LuAG-based garnet fibres: advances and bottlenecks

A technological advance in shaped μ-PD crystal growth provided us with high-quality single crystalline fibres of rare-earth garnets with the good longitudinal transparency and light attenuation length of up to 1 m.

Dynamic force spectroscopy for quantifying single-molecule organo–mineral interactions

Organo–mineral interactions have long been the focus in the fields of biomineralization and geomineralization, since such interactions not only modulate the dynamics of crystal nucleation and growth but may also change crystal phases, morphologies, and structures.

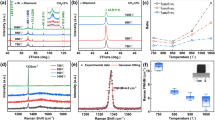

Spectral characteristics of a Nd 3+ /Yb 3+ :YPO 4 single crystal with strong multi-wavelength emission

We report the growth and spectral characteristics of the 0.32 at%Nd 3+ /1.2 at%Yb 3+ :YPO 4 crystal.

Graphene-induced growth of Co 3 O 4 nanoplates with modulable oxygen vacancies for improved OER properties

Graphene-induced growth of Co(OH) 2 nanoplates from Co 3 O 4 nanospheres was reported, showing an ultralow overpotential of 240 mV at 10 mA cm −2 and a Tafel slope of 107.8 mV dec −1 .

Supporting ultrathin “fish scale-like” BiOBr nanosheets on Bi 6 Mo 2 O 15 sub-microwires for boosting photocatalytic performance

A BiOBr/Bi 6 Mo 2 O 15 edge-on heterostructure with fast electron transport could improve interface conductivity and accelerate charge-separation efficiency.

Investigation of various fatty acid surfactants on the microstructure of flexible hydroxyapatite nanofibers

The synthesis of hydroxyapatite nanofibers using various fatty acids and their influences on HA crystal characteristics were systematically explored.

In situ reconstruction of ZIF-8 loaded on fibrous supports

The fibre-supported ZIF-8 can undergo a full degradation–recrystallization cycle in a vapor phase with partial recovery of its porosity.

The synthesis and formation mechanism of nonpolar InN nanoplates

High-crystal-quality nonpolar indium nitride (InN) nanoplates were synthesized via deploying controllable chemical vapor deposition (CVD) technology using the M -plane of GaN nanowires (NWs) as a template.

A plastically bendable and polar organic crystal

An organic crystal of the polar space group Pc that is capable of plastic bending is reported, and its high dielectric constant and strong second-order harmonic generation (SHG) effect have been demonstrated.

Vapor–liquid–solid growth of 4H-SiC single crystal films with extremely low carrier densities in chemical vapor deposition with a Pt–Si alloy flux and X-ray topography analysis of their dislocation propagation behaviors

The CVD–VLS process for 4H-SiC films with a Pt–Si alloy flux achieved their low carrier densities of ∼10 15 cm −3 , demonstrating a remarkable etch back effect and a possible conversion of TEDs and TSDs in the substrate to BPDs in the films.

Asymmetric metal–organic frameworks with double helices for enantioselective recognition

A pair of homochiral metal–organic frameworks are elaborated by employing flexible enantiopure ligands.

Synthesis of morphology-improved single-crystalline iron silicide nanowires with enhanced physical characteristics

Morphology-improved single-crystalline β-FeSi 2 nanowires with enhanced physical characteristics were synthesized through a pre-deposition method.

Promoted crystallization of silicoaluminophosphate zeolites: an efficient way to accelerate crystallization rate and increase solid yield

SAPO-34 with 100% yield has been synthesized by an acid-assisted method, which is also applicable to the synthesis of other silicoaluminophosphate zeolites.

Competing hydrogen-bonding interactions in a high- T c organic molecular-ionic crystal with evident nonlinear optical response

An organic molecular-ionic crystal of (TPPO–H) 2 SO 4 exhibits moderate NLO response which is twice that of KDP and competing hydrogen-bonding interactions triggered high- T c phase transition.

A temperature-reduced method for the rapid growth of hybrid perovskite single crystals with primary alcohols

In this work, we present the simple and temperature-reduced reactive inverse temperature crystallisation (RITC) method to rapidly grow high-quality organic lead trihalide perovskite single crystals.

Growth mechanism of helical γ-Dy 2 S 3 single crystals

The nonequilibrium evaporation of a high-temperature SnS + Dy 2 S 3 solution leads to the implementation of a VLS-like mechanism of growth of γ-Dy 2 S 3 helical single crystals.

Solvent-assisted synthesis of dendritic cerium hexacyanocobaltate and derived porous dendritic Co 3 O 4 /CeO 2 as supercapacitor electrode materials

Here, we report a solvent-mediated synthetic route for preparing cerium hexacyanocobaltate with a dendritic shape. The porous dendritic Co 3 O 4 /CeO 2 was prepared after annealing at 500 °C, served as a supercapacitor electrode.

Adjacent N→O and C–NH 2 groups — a highly efficient amphoteric structure for energetic materials resulting from tautomerization proved by crystal engineering

A high- T c organic-ionic phase transition crystal obtained from a trivalent cation

The organic-ionic crystal of [1,4,7-triazacyclononammonium] Cl 3 , containing a trivalent cation, shows a high-temperature phase transition coupled with dielectric switching.

AB 11 O 16 (OH) 2 (A = K and Cs): interpenetrating 2D layers with large birefringence

By a cation substitution strategy, two new hydroxyborates AB 11 O 16 (OH) 2 (A = K and Cs) were synthesized, and KB 11 O 16 (OH) 2 exhibits a short DUV cutoff edge (195 nm) and a large birefringence.

Supercritical hydrothermal synthesis of UO 2+ x : stoichiometry, crystal shape and size, and homogeneity observed using 23 Na-NMR spectroscopy of (U, Na)O 2+ x

The hydrothermal synthesis of pure uranium dioxide under supercritical water (SCW) conditions was investigated using a starting material composed of a uranyl( VI ) nitrate solution at 450 °C.

The crystallization morphology and process of stereocomplex crystallites of polylactide under CO 2 : the effect of H-bonding and chain diffusion

The crystallization of PLA SC under CO 2 was in situ investigated for the first time.

Pair of chiral molecular ladders and successive hydration in single-crystal-to-single-crystal mode

Self-assembly of Zn(NO 3 ) 2 with a pair of new tridentate chiral Ls produced a pair of chiral ladder-type 1D coordination polymers, where crystals were transformed into different hydrated products of zigzag 1Ds depending on chirality in the SCSC mode.

New insight into the inductive effect of various seeds on the template-free synthesis of ZSM-5 zeolite

This work enables us to obtain an improved understanding of the role of seeds in the template-free synthesis of zeolite.

Exploration of structural transition phenomenon in flexible metal–organic framework formed on polymer substrate

We investigate the structural transition of directly formed flexible MOF crystals on a polymer substrate.

High-temperature inverted annealing for efficient perovskite photovoltaics

High-quality perovskite films with large grains and reduced surface defects were obtained via an inverted annealing process. Corresponding photovoltaic devices achieved a highest efficiency of 20.4% with a stabilized power conversion efficiency (PCE) of 19.8%.

Effect of the growth pulling direction on 3D anisotropic stress during different stages of semitransparent Li 2 MoO 4 growth

The three dimensional thermal stress field was calculated for different growth stages of a Li 2 MoO 4 (LMO) crystal grown in an inductively heated Czochralski furnace using the anisotropy and temperature-dependent mechanical properties.

Opposite effects of cations in enhancing and suppressing nucleation in the pathological crystallization of gout

“Opposite effects” were shown by cations, enhancing nucleation followed by suppressing nucleation at physiological pH and ionic strength.

Nucleation behaviour of racemic and enantiopure histidine

Small non-centrosymmetric domains are observed in the racemic crystal, due to the low nucleation activation energy of the conglomerate.

Polycyclic motif engineering in cyanostilbene-based donors towards highly efficient modulable emission properties in two-component systems

Cynostilbene based two-component materials are fabricated which exhibit tunable structures and excellent photophysical properties depending on the IP of the polycyclic moiety and organization of the donor-acceptor in the condensed phase.

Crystallization of paracetamol from mixtures of ethanol and water in a planar oscillatory flow crystallizer: effect of the oscillation conditions on the crystal growth kinetics

Crystal growth kinetic data is reported for a planar oscillatory flow crystallizer.

Sequential variation of super periodic structures emerged in Bi-layered perovskite pillar-matrix epitaxial nanocomposite films with spinel ferrites

The phase stability of Aurivillius bismuth-layer structured Bi 5 Ti 3 FeO 15 (BTFO15) has been investigated in an epitaxial pillar-matrix nanocomposite system with spinel ferrites.

Formation of double-cone-shaped ZnO mesocrystals by addition of ethylene glycol to ZnO dissolved choline chloride–urea deep eutectic solvents and observation of their manners of growth

ZnO mesocrystals were grown in ZnO dissolved CU-DESs with addition of ethylene glycol. Their manner of growth was observed and discussed.

Investigation of the blue color center in β-Ga 2 O 3 crystals by the EFG method

This work investigated the blue color center in β-Ga 2 O 3 crystals grown by the EFG and obtained an effective method to eliminate it.

Reactive molten-flux assisted syntheses of single crystals of Cs 19 Ln 19 Mn 10 Te 48 (Ln = Pr and Gd) crystallizing in a new structure type

Two new complex layered quaternary tellurides, Cs 19 Ln 19 Mn 10 Te 48 (Ln = Pr and Gd), were synthesized by the reactive molten flux method. The title compounds represent an unprecedented structure type.

Protein crystallisation facilitated by silica particles to compensate for the adverse impact from protein impurities

Nanonucleants for protein crystallisation in the presence of impurities.

Protein crystallisation with air bubble templates: case of gas–liquid–solid interfaces

Crystal formation on air bubble–liquid interface, as soft template to efficiently prompt nucleation of proteins.

Synthesis, structural characterization, and luminescence properties of heteroleptic bismuth-organic compounds

The synthesis and photoluminescent properties of four bismuth-organic compounds, their lanthanide doped analogs, and an isostructural europium complex are reported.

Taming CL-20 through hydrogen bond interaction with nitromethane

A novel cocrystal explosive of CL-20/nitromethane in a 1 : 2 molar.

Two Zr-based heterometal–organic frameworks for efficient CO 2 reduction under visible light

Two novel zirconium-based heterometal–organic framework catalysts can effectively improve photocatalytic activities for CO 2 photoreduction under visible light.

Photoluminescence study of N-rich B-doped diamonds grown in NiMnCo solvent before and after annealing

Incorporation of boron substantially decreases the luminescence of centers (NV − , Ni–N, and Co–N) in nitrogen-rich boron-doped diamonds before and after HPHT annealing.

Growth, spectral and laser properties of a Yb-doped strontium yttrium phosphate crystal with a disordered structure

A novel disordered crystal Yb:YSr 3 (PO 4 ) 3 is grown by the Czochralski method. Results indicate that it can be a promising candidate for ultrashort pulse generation and tunable broadband solid-state lasers.

Multilevel strategies for the composition and formation of DAAF/HNIW composite crystals

Insensitive energetic materials are still a great challenge for potential applications.

Competition between diamond nucleation and growth under bias voltage by microwave plasma chemical vapor deposition

A competition between diamond nucleation and growth is proposed in which the surface and bulk nucleation coexist and compete.

Green solvent assisted preparation of one-dimensional CsPbBr 3 nanocrystals with a controllable morphology for cyan-emitting applications

Upon tuning the polarity of antisolvent medium, the length of CsPbBr 3 NCs realizing the conversion from nanorods to NWs. Furthermore, the width of the NWs can be adjusted feasibly via the overgrowth of CsPbBr 3 NWs.

Suppressing barite crystallization with organophosphorus compounds

A naturally derived phosphorous-containing molecule, phytate, functions as a dual inhibitor of barium sulfate (barite) nucleation and growth, making it a potentially viable environmentally-friendly alternative to current barite scale treatments.

Reversed crystal growth of metal organic framework MIL-68(In)

A reversed crystal growth mechanism of MIL-68(In) is revealed. Nanorods of MIL-68 aggregate in parallel into microrods, followed by surface recrystallisation into a single crystal hexagonal shell and extension of crystallisation from surface to core.

Strong intermolecular interaction induced methylene-bridged asymmetric heterocyclic explosives

Methylene-bridged asymmetric heterocyclic explosives were designed and synthesized to attempt the possibility of realizing energetic materials with high-energy and adequate sensitivity.

Growth mechanism on graphene-regulated high-quality epitaxy of flexible AlN film

We report a novel diffusion–adsorption regulation growth method in the epitaxy of AlN on graphene for the high-quality and transferable large-size AlN film.

Involvement of various anions in tuning the structure of silver( I ) coordination polymers based on a S-donor ligand: syntheses, crystal structure and uptake properties

Ag( I ) coordination polymers based on a S-donor ligand containing of various anions were synthesized and characterized. Also, the absorption potential of the polymers was examined by the NH 3 and H 2 S gases.

Temperature-dependent phase composition of fluorinated zinc phthalocyanine thin films and their sensing properties towards gaseous NO 2

This work presents a temperature-dependent phase composition study of thin films (200 nm) of fluorinated zinc phthalocyanines (4F, 16F) and their chemiresistive response towards NO 2 gas.

Crystal growth and properties characterization of Nd 3+ :Na 5 Lu(MoO 4 ) 4 for continuous multi-wavelength NIR laser emission

The Nd 3+ :Na 5 Lu(MoO 4 ) 4 crystal was grown in a 4Na 2 O–5MoO 3 flux through the top-seeded solution growth technique, and achieved a continuous multi-wavelength NIR laser emission in the Nd 3+ :Na 5 Lu(MoO 4 ) 4 crystal for the first time.

Sisal-like Sn 2+ doped ZnO hierarchical structures: synthesis, growth mechanism, and their application in photocatalysis

Sisal-like Sn doped ZnO hierarchical structures were prepared by the hydrothermal method without employing templates or matrices. The architectures show enhanced light absorption, high photocatalytic properties, good stability and reusability.

Fabrication of a 2 inch free standing porous GaN crystal film and application in the growth of relaxed crack-free thick GaN

This paper describes the fabrication of a 2 inch free standing porous GaN crystal film and the application in the growth of relaxed crack-free thick GaN.

Growth of a large-aperture mid-infrared nonlinear optical La 3 Nb 0.5 Ga 5.5 O 14 crystal for optical parametric chirped-pulse amplification

A high optical quality 60 mm-diameter LGN crystal with wide transparency was grown by the Czochralski method. The origin of the wide transparency as for a traditional oxide crystal was investigated from the viewpoint of crystal symmetry.

Five new rubidium borates with 0D clusters, 1D chains, 2D layers and 3D frameworks

By tuning the synthetic conditions, borates with 0D clusters were transformed into a 1D chain, 2D layer and 3D framework.

Crystallization of paracetamol from aqueous solutions in a planar oscillatory flow crystallizer: effect of the oscillation conditions on the nucleation kinetics

Nucleation kinetic data is reported for a planar oscillatory flow crystallizer.

Simple and facile one-step synthesis of bowl-like hollow ZSM-5 zeolites

One-step synthesis of bowl-like hollow ZSM-5 zeolites via controlling the the hydrolysis temperature of TEOS.

Two pairs of chiral lanthanide–oxo clusters Ln 14 induced by amino acid derivatives

Two pairs of chiral lanthanide–oxo clusters L -/ D -Ln 14 (Ln = Y/Dy) have been obtained under the action of anion template. The solid-state circular dichroism (CD) spectra of L -Y 14 / D -Y 14 and L -Dy 14 / D -Dy 14 displayed mirror symmetry effects.

Growth of MSe semiconductor nanowires on metal substrates through an Ag 2 Se-catalyzed solution–solid–solid mechanism (M = Zn, Cd and Mn)

Solution-phase growth of MSe nanowires on their respective metal foil or flakes (M = Zn, Cd and Mn) has been realized by a recently developed solution–solid–solid mechanism initiated by preexisting Ag 2 Se seeds.

Quality improvement mechanism of sputtered AlN films on sapphire substrates with high-miscut-angles along different directions

We studied the annealing mechanism of the films with high-miscut-angles at low cost and high efficiency and revealed the essence of annealing to improve the film quality lies in the annihilation of grain boundaries during the recrystallization.

New phase transition pattern of fivefold twins transformed into lamellar structure in Ti 3 Al alloy

A new phase transition pattern of fivefold twins into a lamellar structure leading to a second phase transition was found in Ti 3 Al alloy.

Metastable growth and infrared spectra of CuB 2 O 4 :Ni single crystals

The formation of CuB 2 O 4 :Ni crystals in fluxes based on Li 2 WO 4 –Bi 2 O 3 –WO 3 has been studied. A distinctive feature of the used flux growing mode is the metastable nature of nucleation. IR reflection and transmission spectra are presented.

Optimized growth and anisotropic properties of Li 2 ZrTeO 6 nonlinear optical crystals

Centimeter-sized and high-quality Li 2 ZrTeO 6 crystals were grown by a modified top-seed solution growth method. The excellent thermal properties indicate that Li 2 ZrTeO 6 is an excellent candidate suitable for high-power nonlinear optical applications.

About this collection

The latest research on Crystal Growth published in CrystEngComm .

Advertisements

- Open access

- Published: 31 January 2020

Current status of solid-state single crystal growth

- Iva Milisavljevic 1 &

- Yiquan Wu 1

BMC Materials volume 2 , Article number: 2 ( 2020 ) Cite this article

19k Accesses

24 Citations

Metrics details

Fabrication of single crystals has long been limited to melt- and solution-growth techniques. However, in recent years solid-state single crystal growth (SSCG) has appeared as a promising alternative to the conventional techniques due to its cost-effectiveness and simplicity in terms of processing. Moreover, the SSCG technique has enabled the fabrication of single crystals with complex chemical compositions and even incongruent melting behavior. A recently proposed mechanism of grain boundary migration known as the “mixed control mechanism” and the associated principles of microstructural evolution represent the basis of the SSCG technique. The mixed control mechanism has been successfully used to control the key aspects of the SSCG technique, which are the grain growth and the development of the microstructure during the conversion process of the single crystal from the polycrystalline matrix. This paper explains in brief basis of the mixed control mechanism and the underlying principles of microstructural evolution in polycrystalline materials and provides a comprehensive overview of the most recent research on single crystal materials fabricated via the solid-state single crystal growth technique and their properties.

Introduction

A need for single crystal fabrication.

Single crystals are one of the most important groups of materials due to their continuous, uniform, and highly-ordered structure which enables them to possess unique properties. In many aspects, single crystal materials can be found to be advantageous over polycrystalline materials, and many properties which are found in single crystals cannot be replicated in polycrystals [ 1 ]. Currently, even with the technological developments of advanced polycrystalline materials which are designed for specific applications, the electrical, optical, thermal, mechanical, and other properties of single crystals still remain superior. For these reasons, it is not surprising that single crystals, and the methods for their fabrication, are a topic of interest among many researchers.

Single crystals have found extensive use in optical, electronic, optoelectronic, and other applications. Specifically, single crystal semiconductors are one of the most widely researched and used materials. These materials have been applied for various electronic and optoelectronic devices and components, such as light-emitting diodes (LEDs), photodetectors, wide-bandgap devices, high-power lasers, consumer electronics, and more [ 2 , 3 ]. For example, current computer chip production is not possible without high-quality single crystal silicon (Si) wafers [ 4 ]. Due to their outstanding optical and electronic properties, single crystals of III–V semiconductors, such as GaAs, GaN, InP, InAs, and others, are an integral part of devices for application in fiber-optic communication, wireless and satellite communication, solid-state lighting, and more [ 2 ]. The importance of single crystal alumina, also known as sapphire, as well as yttrium aluminum garnet (YAG), for laser materials has also been demonstrated through numerous applications. Sapphire has been used in the electronics industry both as a passive substrate material and active device (e.g. silicon-on-sapphire); likewise, it is used for rocket domes, optical data storage, radiation detection, LED devices, optical windows, and other applications [ 5 ]. On the other hand, YAG single crystals, and especially Nd 3+ -doped YAG, are known for their important application in solid-state laser devices, such as waveguide lasers [ 6 ] and single crystal fibers for high-power lasers [ 7 ], as well as scintillation crystals, and others. Piezoelectric single crystal materials, which were initially developed and utilized as transducers for sonar devices and medical ultrasonic diagnostic devices, have also been applied in sensors, actuators, medical transducers, energy harvesters, and more [ 8 , 9 ]. As it can be seen, single crystal materials are capable of covering a wide variety of applications, which range from scientific- and research-related to daily life.

Another important use of single crystal materials is as substrates for films of different materials; this enables a whole new collection of applications. Single crystals can be used not only as a mechanical support or a surface at which layer or layers of materials are being deposited but can also act as a single crystal seed during epitaxial growth [ 10 ], when the deposited film takes on orientation of the substrate, and sometimes even a lattice structure. Likewise, the fabrication of single crystal epitaxial films on various substrates, which are a vital part of a wide range of devices for electronic, optoelectronic, magneto-optic, and many other applications, although very challenging, is an important goal in the thin film industry due to the numerous advantages of single crystal films [ 11 ].

As technological development increases, the need for high-quality single crystal materials, both in bulk and in thin films, grows simultaneously. The availability of various single crystal materials has enabled the development of a new generation of electronic, optical, optoelectronic, and other devices. However, growth of high-quality single crystals, with stable and reproducible quality, low defect density, with various chemical compositions and sometimes even extreme thermodynamic properties is still one of the greatest challenges today [ 12 ]. Furthermore, techniques which are currently used for growing single crystals experience many processing-related difficulties despite the technological advancements made throughout the years [ 13 ]. Therefore, a high demand for various single crystal materials has imposed a need for improving the growth techniques that are currently used as well as developing new, alternative single crystal growth techniques.

Conventional techniques of single crystal growth

Currently, there are three general approaches for the growth of bulk inorganic single crystals: growth from melt, solution and vapor phase.

Growth from melt is the most commonly used method and is based upon the solidification and crystallization of a melted material. The Czochralski and Bridgman methods are the two most utilized melt-growth techniques. The Czochralski method (Cz) is, for example, very important for the production of single crystals for electronic and optical applications, such as silicon and germanium single crystals, as well as some fluoride and oxide single crystals [ 13 ]. Single crystal growth from melt allows for the fabrication of large single crystals of excellent quality in a relatively short time when compared to other growth techniques [ 14 ]. However, the melt-growth technique shows some disadvantages as well, such as difficulties in maintaining a stable temperature during the crystal growth and in achieving very high melting points for some materials, achieving chemical homogeneity, especially in the case when multiple elements are present in the system, reactivity of the melted material with the crucible, and high costs of production and equipment.

Unlike the melt-growth technique, in which the material is melted first, the solution-growth technique involves the dissolution of the material to be crystallized within a suitable solvent or flux (e.g. PbO, PbF 2 , Bi 2 O 3 , Li 2 O, Na 2 O, K 2 O, KF, P 2 O 5 , etc.) [ 13 , 15 ]. Out of all the solution-growth techniques, high-temperature solution-growth, also known as flux-growth, has been the most utilized technique for the fabrication of single crystals thus far. This technique is especially convenient for materials that incongruently melt or when melt-growth techniques cannot be applied. The main advantage of this technique is that the crystals are grown below their melting temperatures and the growth of the crystal occurs spontaneously through nucleation or crystallization on a seed. On the other hand, the crystal growth rates for the solution-growth method are much slower than that of the melt-growth method and the presence of flux ions is unavoidable in the crystal. Growth of single crystals via the flux method has found many important applications in the production of single crystal materials such as garnets, various laser crystals, including borates, LiNbO 3 , BaTiO 3 , BaB 2 O 4 , and more complex systems such as Sr 1− x Ba x Nb 2 O 6 , Pb 1− x Ba x Nb 2 O 6 , and others [ 13 ].

Vapor-phase growth is the third method of growing single crystals, although it is more commonly applied to the fabrication of thin single crystals films on substrates than bulk single crystals. The growth of single crystals through the vapor phase can be accomplished via a sublimation process, reaction in the gas phase and transport reaction, such in the case of chemical vapor transport (CVT) and, physical vapor transport (PVT) [ 16 ]. Compared to the melt-growth method, the vapor-growth method utilizes lower processing temperatures which result in a significantly higher quality crystal due to avoidance of incorporating impurities, structural and compositional uniformities, and phase transitions. On the other hand, the low growth and transport rates in the vapor to the interface, associated with the low temperature, make this technique less favorable when compared to the other two growth techniques. However, this technique is still used if neither one of the other two techniques is applicable for the growth of single crystals, which is the case in, for example, SiC single crystals [ 15 ].

New technique for single crystal fabrication

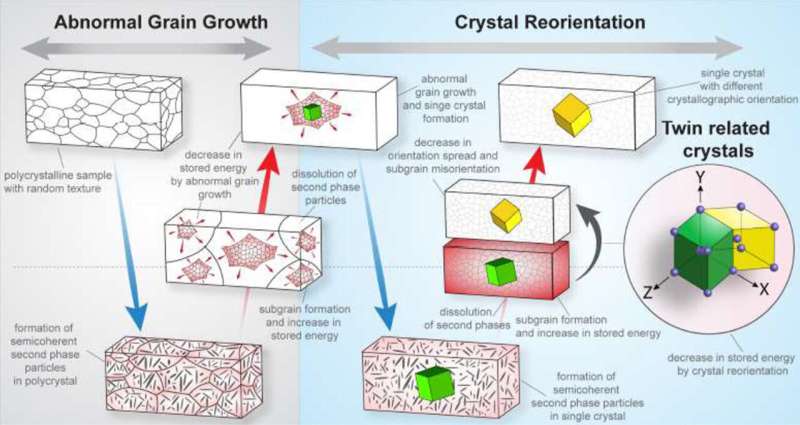

Another pathway for growing single crystals which has recently received attention within the research community, is through the solid-state conversion of polycrystalline materials to single crystals. This method is based on a phenomenon which can be observed in many systems, known as abnormal grain growth (AGG).

Solid-state single crystal growth was first observed and studied in metals as a possible alternative to very difficult and expensive procedures used to fabricate metal single crystals. Most of the research on single crystal conversion in metals date to the middle of the last century and include the reports on single crystals of Fe, Mo, W, and other metals [ 17 , 18 , 19 ]. Later on, in the early 1980s, applying the same principles observed in the metal systems, Matsuzawa and Mase [ 20 , 21 ] performed research on the growth of single crystals from various polycrystalline oxide materials, including ferrites, garnets, and spinels. They demonstrated that single crystal growth using the solid-state conversion approach, which was reserved only for metals at the time, could also be applied to more complex materials’ systems. Furthermore, many issues associated with conventional single crystal growth techniques, such as heating at high temperatures, maintaining compositional uniformity, contamination from the crucibles, etc., were avoided during the solid-state single crystal growth and performed with much lower production costs. In the years that followed, most of the research focus was on BaTiO 3 and Pb(Mg 1/3 Nb 2/3 )O 3 ‒PbTiO 3 systems, however, still in a limited number.

Although it was observed for the first time decades ago, solid-state single crystal growth can still be considered to be a relatively new technique since it did not receive significant attention from the research community until recently once more work had been done. Due to considerable advancements made in nanotechnologies and sintering technology that have enabled the fabrication of high-quality ceramics, interest in solid-state single crystal growth from polycrystals has been renewed. Solid-state single crystal growth has been shown to be an effective and simple technique for obtaining single crystals with lower capital costs associated with production equipment and components, which could potentially allow for the mass production of single crystals for various existing as well as new applications [ 22 ]. The technique utilizes conventional sintering equipment, such as simple furnaces, which cost notably less than the equipment for conventional single crystal growth [ 23 ]. For comparison, a furnace for Cz growth of sapphires can cost between $400,000 and $1,000,000 [ 14 ], while regular furnaces can cost at least an order of magnitude less. Furthermore, the more complex the composition is, the harder it becomes to fabricate a single crystal using the conventional single crystal growth route, due to chemical inhomogeneities, the presence of elements that melt incongruently, volatility of certain elements, and so on. Therefore, solid-state single crystal growth has been found to be promising and applicable to many different systems, especially systems with complex chemical compositions. Net-shape production, when compared to cutting and shaping from the single crystal boules grown conventionally [ 14 ], is another advantage in cost-effectiveness of single crystals produced by solid-state growth since it reduces the number of machining steps after the growth process and even allows for growth of more complexly-shaped single crystals.

This review article will provide an overview of the current status of techniques utilized for the solid-state conversion of single crystals (here, solid-state single crystal growth (SSCG) will be used with the same meaning) and the principles behind them, including AGG, boundary migration, and microstructural evolution. Also, recent reports on the solid-state conversion of single crystals in different systems will be summarized and the most important findings highlighted. The review will be concluded with a discussion on some of the biggest challenges of the SSCG technique, followed by a brief summary and a future outlook.

Solid-state conversion of single crystals from polycrystals

In recent years, solid-state single crystal growth (SSCG) has emerged as a promising alternative technique for growth of single crystals through a conversion process in polycrystalline materials. This technique, which offers numerous advantages over conventional single crystal growth techniques, is based on the occurrence of AGG in polycrystals. More precisely, SSCG technique is developed around what is known as a “mixed control mechanism” [ 24 ] of grain boundary migration as well as principles of microstructural evolution. The mixed control mechanism can be used as a general guiding principle for suppressing growth and controlling the growth of single crystals from polycrystalline materials, which are the key requirements for SSCG.

In this section, the phenomenon of abnormal grain growth will be briefly explained and discussed. Furthermore, the mixed control mechanism of grain boundary migration and the principles of microstructural evolution will be presented and explained. However, for more details on the mixed control mechanism and the related phenomena, the reader is strongly encouraged to refer to the research articles of Dr. Kang and his associates who developed the mixed control mechanism and have conducted extensive research work in this field.

Abnormal grain growth (AGG)

In general, there are two different types of grain growth which can be observed during sintering. One, known as normal grain growth (NGG), involves a uniform rate of grain growth via thermally activated grain boundary migration which results in a uniformly developed microstructure with respect to the sintering time (stationary grain growth). The other type of grain growth is non-normal grain growth (non-NGG) and instead follows a non-stationary grain growth [ 23 ]. AGG is a type of a non-NGG and is referred to as the grain growth where a certain number of grains experience a much faster growth rate than the neighboring grains in the matrix. Such growth may significantly change a grain size distribution, leading to broadening or even a bimodal grain size distribution. With extended annealing time, the abnormal grains gradually increase in size by consuming the surrounding matrix grains until they impinge upon each other. This lowers the driving force for further growth of abnormal grains and they usually stop growing at this stage [ 25 ].

In general, AGG is a phenomenon which is not favorable during materials processing since the presence of abnormally grown grains may have a negative effect on microstructure development, and therefore on the physical properties of materials. The appearance of AGG has been observed in many different systems both ceramic and metallic. Many authors have tried to explain the occurrence of AGG, suggesting different mechanisms and models, however, the underlying reasons for AGG are still under debate [ 26 ]. Generally, the following phenomena have been suggested as the possible causes of AGG: (a) the presence of second phases, pores or impurities (b) high anisotropy of the interfacial energy and grain boundary mobility, and (c) the presence of a thin liquid film at the grain boundary which facilitates grain boundary mobility [ 23 , 24 ]. As explained in [ 23 ], in all of the aforementioned phenomena, it was originally thought that AGG was a result of atomic diffusion across the grain boundary. However, neither of these models could explain, nor be entirely applied to all of the systems which were studied thus far. Therefore, another explanation or model was necessary to more clearly explain the phenomenon of AGG.

Recently, a “mixed control mechanism” was proposed to explain AGG and other types of grain growth behavior; this further enabled the definition of the principles of evolution of the microstructure in polycrystalline materials [ 23 , 27 ].

- Mixed control mechanism

The classical understanding of the mechanisms of AGG, which were mentioned in the previous section, provide explanation for grain boundary migration which is based on atomistic diffusion. These models, however, can only be applied to some specific cases; for this reason, the mixed control mechanism, which is a more universal model, was suggested to explain different grain growth behaviors. The mixed control mechanism has its roots in the theories of crystal growth and experimental observations and explains the phenomenon of grain boundary migration considering the atomic structure of grain boundaries; this has not been taken into account in classical grain growth theory [ 24 ].

There are two different types of grain boundaries which can be identified by differences in structure. One is a rough (round) grain boundary which exhibits an atomically disordered structure, and the other is faceted grain boundary, whose interface is smooth and atomically ordered. In some recent studies [ 27 , 28 , 29 , 30 , 31 ], it was observed that the type of grain boundary has the most significant influence on the occurrence of AGG. While rough grain boundaries were observed to result in NGG, faceted grain boundaries were more likely to undergo AGG (or some other non-normal type of grain growth) [ 24 , 32 ]. In other words, the presence of faceted grain boundaries in the system can be regarded as a prerequisite for AGG. Such a phenomenon was explained by differences in the grain boundary mobilities of rough and faceted boundaries with regard to the driving force for grain boundary migration [ 33 ].

In the case of rough interfaces, grain boundary migration has been shown to have a direct relationship with respect to the driving force for the grain growth. Because of their atomically disordered structures, rough interfaces allow for a large number of attachment sites for atoms, which then enables a high rate of interfacial reactions. Since the migration kinetics are governed by the slowest process, in the case of rough grains, the diffusion, as the slowest process, will be the rate-determining process for grain boundary migration [ 26 ]. On the other hand, for faceted grains, the experimental results have shown that the grain growth is controlled by either interface reaction (attachment of atoms from one grain to an adjacent grain) or atomic diffusion across the grain boundary, depending on which process is slower. Furthermore, it has been demonstrated that there is a relationship between the grain boundary migration of faceted interfaces and the driving force being non-linear [ 33 , 34 , 35 ].

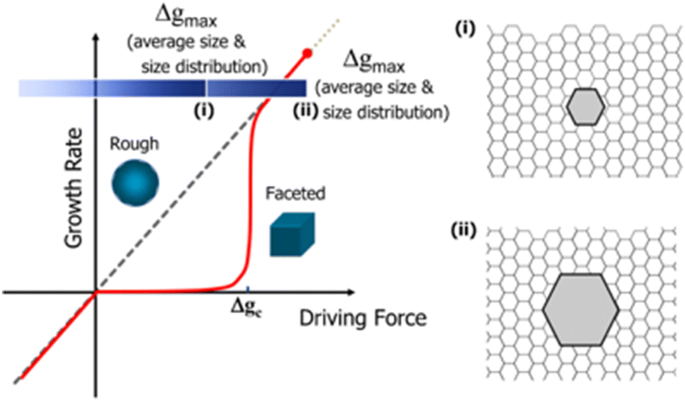

Each individual grain in the polycrystalline matrix possesses its own driving force for grain boundary migration and the maximum driving force for grain growth (Δ g max ) is defined by the average grain size and grain size distribution [ 24 ]. In addition, the maximum driving force is assigned to largest grain in the grain population and increases with decreasing average grain size as well as broadening of the grain size distribution [ 27 ]. Another important parameter in grain growth is the critical driving force (Δ g c ) for grain growth which depends mainly on the type of grain boundary interface and can be changed by varying the temperature, atmosphere, oxygen partial pressure, and presence of dopants [ 24 , 28 , 29 , 30 ].

According to Kang et al. [ 24 ], the ratio between Δ g max and Δ g c determines the type of the grain growth and can even help to further predict and explain the microstructure development. Additionally, the authors explained that there are, in general, four different grain growth behaviors which can be observed depending on the magnitude of Δ g max and Δ g c and their relation [ 24 , 36 ]:

Normal grain growth (NGG), which is a stationary grain growth for which Δ g c = 0 (presented with a dashed line in Fig. 1 ).

Schematic illustration of the mixed control mechanism of grain growth: (left) Mixed control mechanism of grain growth for grains with rough and faceted grain boundaries; (right) Schematic of two systems with different microstructures due to the difference in Δ g max [ 24 ]

Pseudo-normal grain growth, when 0 < Δ g c ≪ Δ g max .

Abnormal grain growth (AGG) occurs when Δ g c ≤ Δ g max .

Stagnant grain growth (SGG) occurs when Δ g max ≪ Δ g c .

In systems with faceted grain boundaries, the growth of faceted grains is governed by the diffusion process when the driving force for growth is larger than the critical driving force. On the other hand, when the driving force is smaller than the critical, the growth rate is significantly smaller than that by diffusion and is led by the interface reaction instead [ 32 ]. Such non-linear grain growth behavior with respect to the driving force is therefore said to be mixed controlled by either a diffusion or interface reaction, as illustrated in Fig. 1 .

AGG, which is the focus of the SSCG method, occurs in systems with faceted grain boundaries. For an efficient solid-state single crystal conversion, it is preferred that the growth of grains within a polycrystalline matrix be negligible (with Δ g max lower than Δ g c ), while the growth of one or a small number of grains (acting as single crystal seeds) is promoted. For the latter case, the driving force should be larger than the critical driving force (Δ g c ) in order for the grains to begin experiencing AGG. For such growth conditions, and in order for single crystal conversion to occur, it is necessary to have a well-balanced ratio between Δ g max and Δ g c [ 23 ]. The average grain size and grain size distribution significantly impact Δ g max and, as a consequence, the ratio between the maximum and the critical driving force, as shown in Fig. 1 . Similarly, a variation in Δ g c , affected by the change in the grain boundary structure, will also impact the microstructural development.

The predictions set by the mixed control mechanism on microstructural evolution can be demonstrated best by observing the effects of a change in Δ g max under constant Δ g c , or vice versa. For example, in the experiments of Jung et al. [ 37 ], when Δ g c was kept constant, Δ g max could be manipulated by changing the initial particle size of the powder sample. As a result, the fine-grained BaTiO 3 sample exhibited AGG, while the same sample, but with coarser particles, underwent SGG due to differences in Δ g max . Such an observation confirms the predictions presented in Fig. 1 . Conversely, when Δ g c was varied, different scenarios could be observed depending on which parameter was affecting the grain boundary structure. A relationship between the change in oxygen partial pressure and the degree of faceting of grain boundaries is one of the best examples of how this parameter can affect the grain boundary structure and therefore lead to AGG; several studies conducted in which BaTiO 3 was used as a model system support this [ 28 , 29 , 37 ]. Other parameters that can affect the grain boundary structure (e.g. doping, temperature and sintering atmosphere) have also been investigated [ 28 , 30 , 33 , 38 , 39 ], and can be seen as an additional endorsement to the concept of the mixed control mechanism.

Furthermore, some experimental studies have confirmed that even different crystallographic directions will experience differences in migration kinetics in systems with faceted grain boundaries [ 33 , 35 , 40 ]. Under some experimental conditions, the migration in certain crystallographic directions was even completely omitted [ 35 ]. According to the authors of the studies, the presence of the critical driving force for grain boundary migration, Δ g c , which varied with crystallographic planes, was the reason for this discrepancy in results. Such observations are consistent with the assumptions of the mixed control mechanism and are further evidence that the microstructural development in the systems with faceted grain boundaries is a result of the non-linear relationship between the grain boundary migration and the driving force for migration.

SSCG technique

Despite the fact that abnormal grain growth was found to be an unwanted event during sintering, the SSCG technique was actually based on this phenomenon [ 41 ]. Furthermore, the SSCG technique was developed as a direct application of the principles of microstructural evolution which further supported the understanding of the mixed control mechanism [ 24 ].

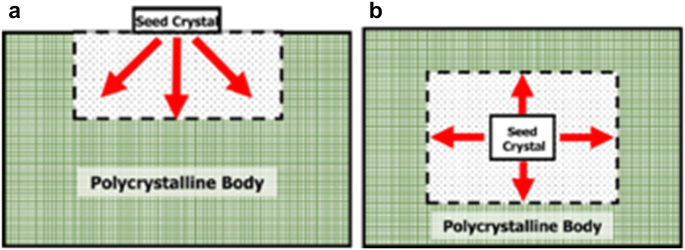

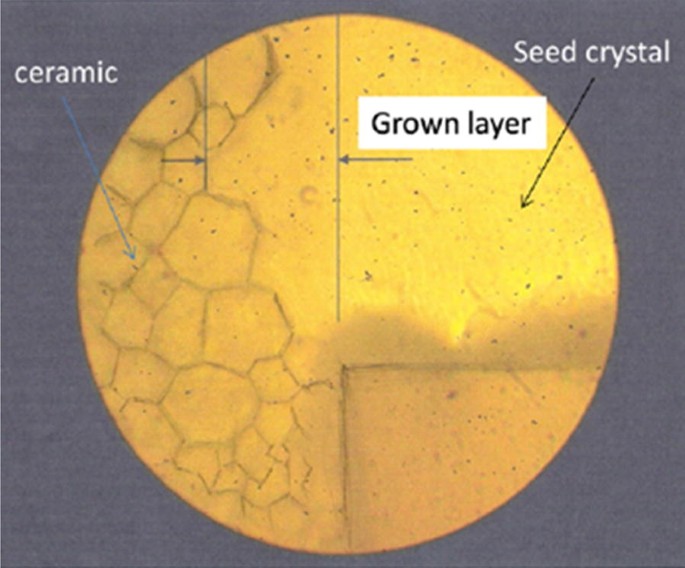

In most practical cases, the SSCG technique uses a single crystal seed of a similar crystalline structure with the matrix material which is either embedded in the polycrystalline green body or placed on top of it, as illustrated in Fig. 2 [ 23 ]; this technique is known in the literature as the seeding method. The seed and the green body are both sintered at a temperature which is below the melting point of the crystal. This enables the formation (or conversion) of the single crystal material from the polycrystals through a controlled AGG process as well as in the crystallographic direction of the seed crystal. Figure 3 depicts the process of conversion where the small matrix grains are being consumed by a large single crystal seed. The same principle is used for the fabrication of single crystals from melt, except in this case, heating well above the melting temperature is necessary and, also, other issues associated with this processing method are difficult to avoid. Furthermore, single crystals can be grown using the “seed-free method” via prior nucleation of the seed crystal in the polycrystalline matrix by applying a temperature gradient or by adding a dopant material [ 23 ]. This method does not require embedding of the single crystal seed in the polycrystalline matrix as in the case of the seeding method, but the principle of the single crystal conversion is the same.

Schematic of the solid-state conversion of single crystal: a Seeding from the top side of the polycrystalline material; b embedding of the seed crystal [ 23 ]

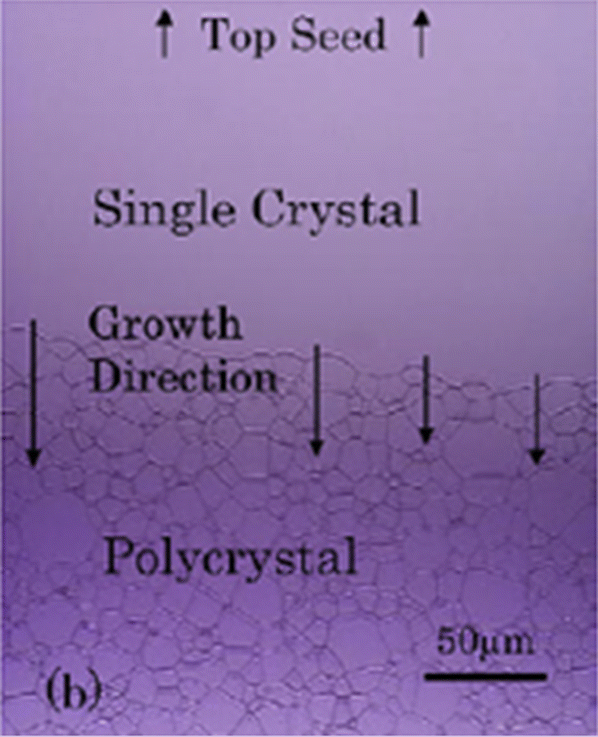

Cross-section of the Nd:YAG single crystal grown by SSCG method [ 42 ]

Although the SSCG method has given very good results thus far, there are still certain aspects which need to be considered and which could be limiting, such as the choice of the seed crystal, density of polycrystalline matrix, size distribution of the grains, structural matching between the seed crystal and matrix, and control of the interface [ 41 ]. So far, the SSCG has been successfully applied to only a limited number of systems which mainly include oxides and piezoelectric ceramic materials.

The following section of this paper will provide an overview of the results which have been reported on single crystal growth via the SSCG technique.

Current developments on solid-state single crystal growth

Pb-based piezoelectric materials.

Solid-state conversion of single crystals has recently been proved to be a very successful way to produce piezoelectric single crystals for commercial usage. For example, single crystals such as Pb(Mg 1/3 Nb 2/3 )O 3 –PbTiO 3 (PMN–PT) and Pb(Mg 1/3 Nb 2/3 )O 3 –Pb(Zr,Ti)O 3 (PMN–PZT) are now produced by the SSCG method, while the conventional methods include growth via Bridgman or flux methods. By using the flux-method, it is difficult to obtain single crystals of size and quality required for the commercial usage. Another issue associated with this method is that it causes vaporization of the toxic PbO substance. With the Bridgman method it is hard, on the other hand, to achieve compositional uniformity within the growing crystal. The SSCG technique, therefore, has appeared as a very promising and effective method for production of lead-based piezoelectrics.

Single crystals of some relaxor-based ferroelectrics, such as Pb(Mg 1/3 Nb 2/3 )O 3 –PbTiO 3 (PMN–PT) exhibit superior properties compared to polycrystalline forms of the same composition. Especially important are PMN–PT materials with 35 mol% of PbTiO 3 added because of their potential application as electromechanical devices. A possibility to grow a single crystalline PMN–PT material by the SSCG method was recognized many years ago. In 1998, Li et al. [ 43 ] used a method of embedding a PbTiO 3 (PT) single crystal into polycrystalline Pb(Mg 1/3 Nb 2/3 )O 3 (PMN), to grow PMN–PT single crystals. A powder with a single crystal was cold isostatically pressed and then sintered and annealed under pressureless conditions in a range of temperatures. The authors were able to observe distinct boundaries between the grown single crystal area and polycrystal grains of matrix material. Khan et al. [ 44 ] reported a solid-state growth of the PMN–35 mol% PT single crystal using the same method which the previously mentioned group of authors used in their study. During preparation of the matrix material, a specific amount of PbO was mixed in. Following the sintering of PMN with the PT single crystal embedded in the material, the compact was annealed at 1150 °C for 10 h. During annealing, PbO was in a liquid phase, which, according to the authors, had a significant impact on the single crystal growth inside the polycrystalline matrix. The authors also showed that as the single crystal boundary migrated through the polycrystalline matrix, PbO as the second phase accumulated at the triple points in the matrix and remained entrapped in a form of spherical inclusions in the grown crystal.

In 2003, another group of authors reported [ 45 ] a study on the same material which included seeding of the PT single crystal in the PMN matrix with a small amount of liquid PbO, added to the matrix to increase the grain boundary mobility. In this study, the authors used a vacuum hot-pressing furnace following cold isostatic pressing of the green pellets to obtain the compact. They observed a clear boundary between the single crystal and polycrystal area. But what is more important, they observed a notable difference between the samples in which the liquid PbO was not added and when it was included in the matrix. A small amount of the liquid PbO increased the single crystal growth constant by nearly 100 times.

A common issue which was observed in all the previously mentioned studies was that the grown single crystals contained a significant number of pores as well as a PbO second phase entrapped inside the structure. This negatively affected the properties of the single crystals. An interesting observation made by Kim [ 45 ] was that the single crystal seed orientation had a great influence on the elimination of the PbO liquid phase from the grown single crystal.

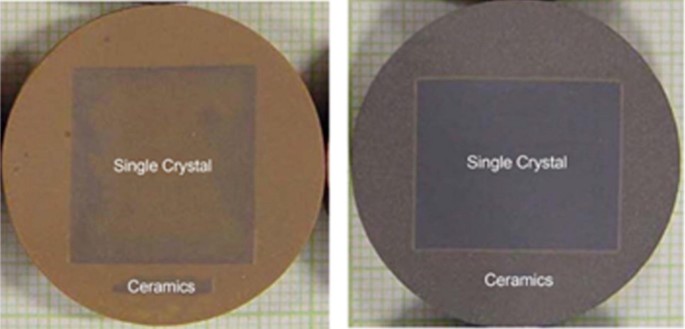

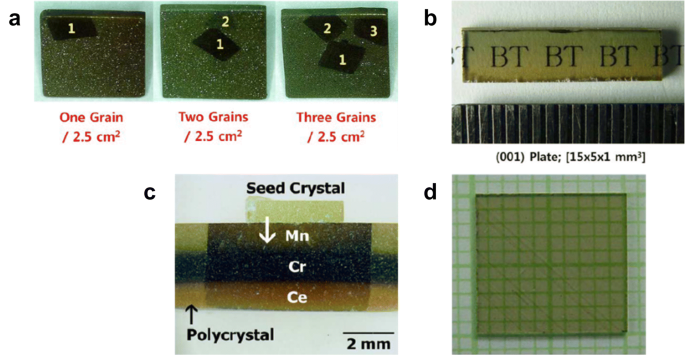

Despite the issues related with the growth of PMN–PT single crystals in laboratory conditions, this type of material was successfully fabricated by scaling-up the SSCG process for commercial purposes. It is interesting to mention that by the SSCG method, it is possible to grow both undoped and doped (e.g. Fe, Mn) PMN–PT single crystals with very high quality and excellent dielectric and piezoelectric properties [ 47 ]. Recently, growth of undoped and Mn-doped 71PMN–29PT high-quality single crystals using the SSCG method were reported [ 46 ], in which excellent piezoelectric and electromechanical properties of both single crystals were demonstrated. With such results, these materials, and especially Mn-doped single crystal, could be utilized as high-power piezoelectric transducers in sonars and medical devices. In this study, undoped and Mn-doped (Mn–PMN–PT) PMN–PT single crystals were fabricated by Ceracomp Co., Ltd. from South Korea (Fig. 4 ), which has become well-known for their production of high-quality piezoelectric single crystals via the SSCG method. In another study, Mn–PMN–PT single crystals were grown into very thin plates (< 0.2 mm) which enabled them to show high stability and piezoelectric performance which is suitable for high frequency composites, medical ultrasound probes, non-destructive testing devices, and flexible devices applications [ 9 ].

Polished surfaces of 71PMN–29PT single crystals grown by SSCG method: (left) undoped and (right) Mn-doped [ 46 ]

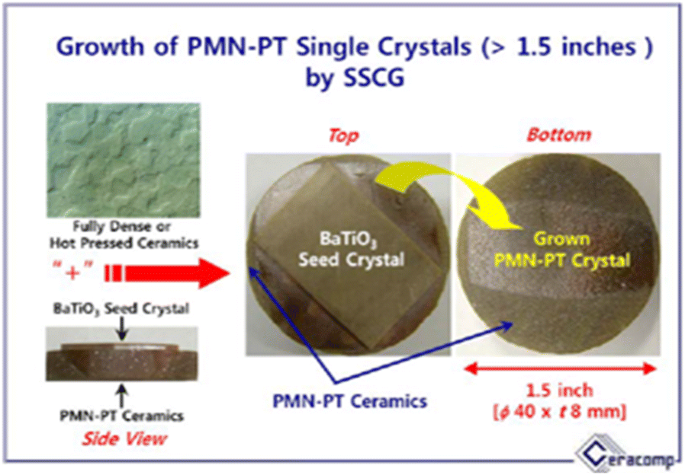

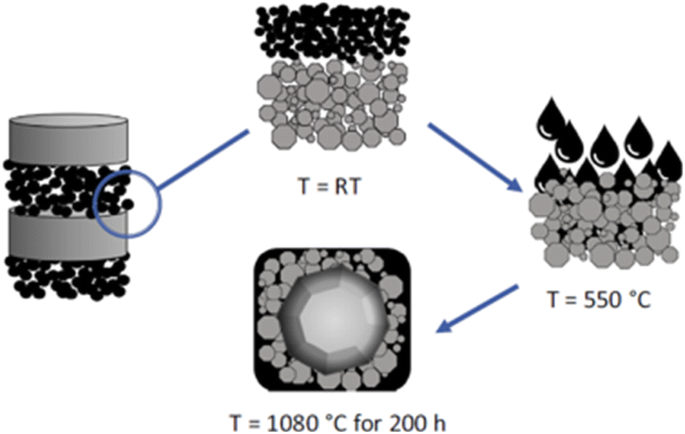

Company Ceracomp Co. also introduced a method for obtaining PMN–PT single crystal ceramics by seeding with a BaTiO 3 single crystal. Figure 5 presents a schematic for obtaining such materials via the SSCG method. First, they prepared a PMN–PT ceramic using a hot-pressing furnace, after which they placed a BaTiO 3 single crystal on top of the ceramic and heat-treated the sample [ 48 ]. Using this process, they were able to fabricate a homogeneous and fully dense PMN–PT single crystal. Hot-pressing of the ceramic compact was found to be very beneficial for obtaining a high-density product at the end.

Schematic of experimental procedure for fabrication of PMN–PT single crystals by SSCG method [ 48 ]

Lim et al. [ 49 ] published their investigation on a ternary system comprised of BiScO 3 –Pb(Mg 1/3 Nb 2/3 )O 3 –PbTiO 3 (BS–PMN–PT) in which they grew a single crystalline BS–PMN–PT via the SSCG method which included embedding of the single crystal Ba(Zr,Ti)O 3 (BZT) into the matrix compact. The authors used four different fluxes (Bi 2 O 3 , LiBiO 2 , PbO/LiBiO 2 and PbO/Bi 2 O 3 ) in which they tried to grow single crystal BS–PMN–PT. The fluxes were added with the intention of enhancing the material transfer by forming a liquid phase during sintering. What they observed was that the PbO/Bi 2 O 3 flux enabled growth of the BS–PMN–PT single crystal from BZT single crystal, while other fluxes were inefficient, which indicated that the BZT single crystal was chemically stable against the PbO/Bi 2 O 3 flux.

Along with the PMN–PT single crystal relaxor ferroelectric, Pb(Mg 1/3 Nb 2/3 )O 3 –PbZrO 3 –PbTiO 3 ternary system, or shorter Pb(Mg 1/3 Nb 2/3 )O 3 –Pb(Zr,Ti)O 3 (PMN–PZT), is a very important material which has numerous applications in areas such as ultrasonic transducers and actuators due to its large piezoelectric coefficient and high electromechanical coupling factors in areas such as medical. Traditionally, these types of single crystal materials were grown via the flux method or the Bridgman method which were found to be costly and usually resulting in chemical inhomogeneity of the grown crystals. Zhang et al. [ 50 ] demonstrated single crystal growth of PMN–PZT by means of the SSCG technique. The matrix compact containing Pb 3 O 4 , MgNb 2 O 6 , ZrO 2 , and TiO 2 was prepared by mixing and pressing of the raw materials into pellets, sintering in the range from 1100 to 1200 °C, followed by hot isostatic pressing of the ceramics. BZT single crystal plates were used as seed crystals for single crystal growth during the SSCG process. The density of such obtained PMN–PZT single crystals was found to be greater than 99% of the theoretical density. The authors further investigated the electromechanical and piezoelectric properties of the fabricated PMN–PZT single crystals and showed that single crystals grown by the SSCG method exhibited properties which were greater than the previously investigated PMN–PT single crystals.

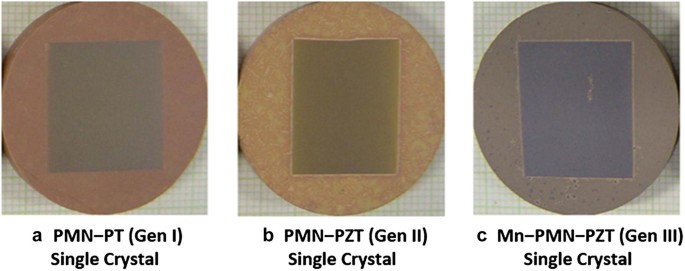

Further investigation on PMN–PZT single crystals obtained by the SSCG method was extended to doping of the same with manganese (Mn), iron (Fe), or even indium (In). In 2017, researchers from the Sunmoon University in South Korea, in collaboration with the Ceracomp Co., presented their study in which they doped single crystal PMN–PZT with Mn [ 8 ]. In this study, the authors used three different generations of piezoelectric single crystal materials (PMN–PT - first, PMN–PZT - second, and Mn-doped PMN–PZT - third generation) obtained by the SSCG method in order to compare the properties of each to one another. The preparation of the single crystals included attachment of the BZT single crystal as a seed crystal, after primary sintering. By applying the SSCG method they were able to obtain high-quality single crystals (Fig. 6 ) which exhibited good piezoelectric properties, among which Mn-doped PMN–PZT was shown to be the most promising.

Three generations of piezoelectric single crystals grown by the SSCG method [ 8 ]

Until now, the SSCG technique was shown to be the only method to produce large relaxor-PZT single crystals, such as PMN–PZT, of different ratios of Pb(Mg 1/3 Nb 2/3 )O 3 (PMN), PbZrO 3 (PZ) and PbTiO 3 (PT). The change of PMN/PZ/PT ratios has a significant influence on materials’ piezoelectric and dielectric properties [ 47 ]. Also, because of the PZ component in the PMN–PZT system, which exhibits incongruent melting behavior, and PbO which is very volatile, PMN–PZT single crystal has been successfully produced only by the SSCG technique so far.

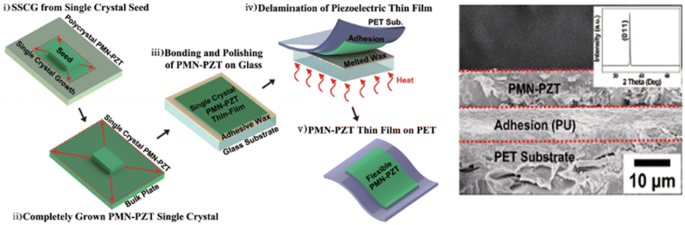

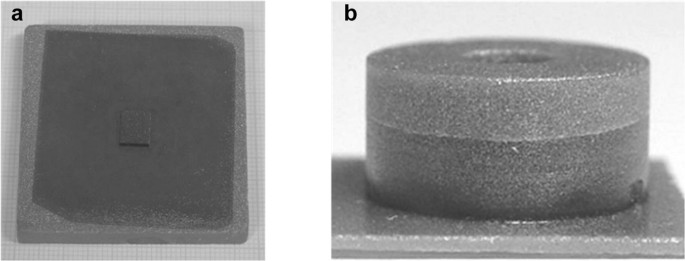

An interesting report which was done by Hwang et al. [ 22 ] in 2015 demonstrated the possibility of fabricating thin film PMN–PZT single crystals by the SSCG method used for the fabrication of a high-performance energy harvester material. The authors used a BZT single crystal seed plate to attach it to the surface of the polycrystalline ceramic during the SSCG process. Afterwards, they were able to take the thin single crystal PMN–PZT film from the glass substrate and transfer it to the plastic substrate without making any damage to the material. A schematic illustration of the whole process is presented in Fig. 7 .

Flexible PMN–PZT thin film single crystal energy harvester: (left) schematic illustration of the SSCG process of fabrication; (right) scanning electron microscope (SEM) micrograph of the cross-section of PMN–PZT single crystal film on plastic substrate [ 22 ]

Pb-free piezoelectric materials

Conventionally, piezoelectric single crystals have been produced via the flux or the Bridgman method. As previously mentioned, these methods require high-temperature treatment for the melting of the raw materials which can, at the end, create chemical inhomogeneity and, more importantly, evaporation of highly toxic substances, such as lead. In the last few decades, the question of environmental and health issues concerning the production of the lead-based piezoelectric single crystal materials has been raised. As the growing market demand for these materials is rising more and more each year, a development of lead-free piezoelectric ceramics and single crystals which will be able to replace lead-based piezoelectric materials became necessary.

This paper will review the two most studied lead-free piezoelectric ceramic materials which were proven to be able to be fabricated by the SSCG technique. The two lead-free piezoelectric materials which will be presented here belong to the KNaNbO 3 (KNN) lead-free family and the (Na 1/2 Bi 1/2 )TiO 3 –BaTiO 3 –(K 1/2 Na 1/2 )NbO 3 (NBT–BT–KNN) family of single crystals.

KNN-based lead-free single crystals

KNaNbO 3 (KNN), a lead-free piezoelectric material has attracted a lot of attention in the past decade because of its desirable properties as a piezoelectric and dielectric, and a potential to replace lead-based piezoelectric ceramics and single crystals. KNN has a perovskite structure and exhibits three phase transitions, at around 160 °C from rhombohedral to orthorhombic phase, at around 200 °C from orthorhombic to tetragonal phase, and at 420 °C from tetragonal to cubic phase [ 51 ]. Of importance regarding this material is that it undergoes AGG during sintering after the temperature reaches a certain critical point, which in turn decreases its piezoelectric properties. On the other hand, such behavior is important in terms of the growth of the single crystal material by the SSCG method.

Two different approaches have been recognized so far which can be used for the fabrication of single crystalline KNN by the SSCG method. One approach utilizes growth of the single crystal by the seeding method and the other can be referred to as the “seed-free” method for the growth of single crystals.

KNN-based single crystals grown by seeding method

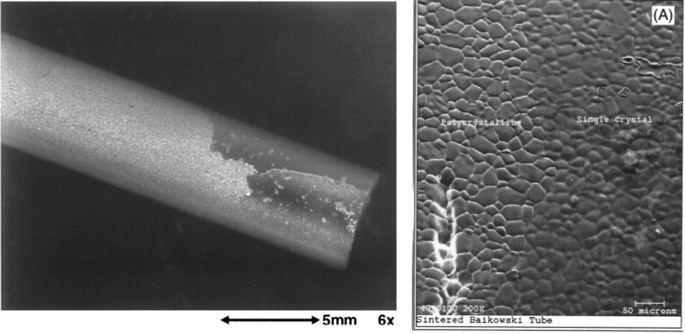

In the study conducted on obtaining single crystal KNN via the SSCG method, Fisher et al. [ 52 ] used a <110> KTaO 3 single crystal as a seed crystal which was found similar to KNN in terms of the unit cell parameters. The single crystal was embedded into the powder matrix and, following this, the green body was prepared by uniaxial pressing and subsequent cold isostatic pressing. The authors’ goal was to investigate the influence of the applied pressure on the quality and porosity of the grown KNN single crystal. They determined that certain loading pressures had significant impacts on the porosity of the grown single crystals. The single crystal obtained by heat treatment under applied pressure in a hot pressing furnace in comparison to the sample heat-treated under pressureless conditions experienced a much smaller number and size of the pores, demonstrating the crucial role of pressure in obtaining a high-density single crystal KNN. The SEM images presented in Fig. 8 depict interfaces between single crystal seed and grown single crystal, and grown single crystal and the polycrystalline matrix in the samples prepared in pressureless and pressure-assisted conditions.

SEM images of KNN single crystal grown by SSCG method in: a , b conventional furnace, and c , d hot pressing furnace [ 52 ]

Benčan et al. [ 53 ] investigated the single crystal growth of KNN and Li, Ta-doped KNN by the SSCG method. Their preparation method for the green compacts was similar to the work of Fisher et al. They also used KTaO 3 as a seed crystal due to its compatibility with KNN. The authors demonstrated that the single crystal growth in the hot press furnace is advantageous over the conventional furnace. They explained that in the conventional furnace, the growth of single crystal, matrix grains, and densification are all happening simultaneously, which might be a reason for the high number of pores left trapped inside the single crystal. Another point they made was on the influence of the addition of the sintering aid (in their case, K 4 CuNb 8 O 23 ) on single crystal growth. The sintering aid was shown to be helpful when 2 mol% was added because it allowed the growth of the matrix grains to some extent, after which the driving force for the single crystal remained constant, allowing the crystal to grow under extended annealing time. On the other hand, a smaller amount of sintering aid (0.5 mol%) was found to cause a reduction of the single crystal and matrix grain growth rates.

Similarly, Yang et al. [ 54 ] studied the single crystal growth mechanism by the SSCG method on a KNN-based piezoelectric material doped with lithium. Sintering of the matrix material with a buried single crystal seed of KTaO 3 was performed in the presence of a sintering aid, MnO 2 . The results demonstrated that the addition of the sintering aid created a liquid phase which resulted in interfacial reactions that significantly affected the crystal growth rate, but only up to a certain threshold. Also, the authors observed a high number of pores, which is the result of the fast movement of the interface between the growing single crystal and matrix grains which tend to increase in size as the growth of the crystal continues [ 54 ].

Although the SSCG method was found promising for growth of the lead-free piezoelectric single crystals, one of the biggest problems associated with this method is in the high porosity of the end product. Uwiragiye et al. [ 51 ] reported in their study on 0.96(K 0.48 Na 0.52 )NbO 3 –0.03(Bi 0.5 (Na 0.7 K 0.2 Li 0.1 ) 0.5 )ZrO 3 –0.01(Bi 0.5 Na 0.5 )TiO 3 in which they used a KTaO 3 seed crystal with <110> orientation, that the piezoelectric properties of the grown single crystal could be enhanced if the porosity of the crystal could be reduced. They observed that the porosity increases with distance from the seed crystals and that the pores are irregular in both shape and size.

KNN-based single crystals grown by seed-free method

Using a single crystal seed to instigate conversion of the polycrystalline matrix grains to a single crystal with a desired crystallographic direction can be achieved by the SSCG method. However, despite the difficulties associated with controlling the growth process, the quality of the grown crystal is also affected by the seed crystal. Therefore, a seed-free method of growing single crystals by the SSCG method has been proposed. This method is known as the seed-free solid-state single crystal growth, or SFSSCG.

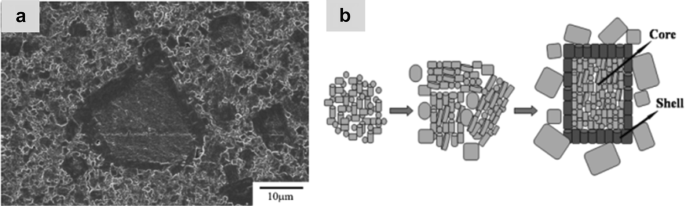

In 2007, Zhen and Li reported their study on growth of single crystals in KNN and (Li 0.04 K 0.44 Na 0.52 )(Nb 0.85 Ta 0.15 )O 3 (LKNNT) ceramic materials prepared and sintered in a conventional way, without seed crystals [ 55 ]. The authors were able to observe a small number of coarse grains which experienced AGG in both samples. While the distribution of these grains was somewhat random in KNN, the distribution of grains in LKNNT was more ordered. An interesting phenomenon which the authors observed was that the abnormal grains had a core–shell structure, as can be seen in Fig. 9 a. Different structural features of the core and shell grains could be observed, but both regions showed to belong to a single crystal grain. Another interesting observation was how the core grains maintained their original grain size; this could not be explained using classical grain growth theory. The authors proposed a schematic explanation for the core–shell structure formation (Fig. 9 b). But despite the AGG, the ceramic materials exhibited good piezoelectric and dielectric properties, showing that the SFSSCG method could be a promising technique for the single crystal growth.

A core–shell structure in KNN: a SEM micrograph; b schematic diagram showing procedure for formation of the core–shell structure [ 55 ]

Following Zhen and Li, many other authors reported successful fabrication of KNN-based single crystals through the SFSSCG method. In 2010, Wang et al. [ 56 ] reported single crystal growth of KNN by utilizing the AGG mechanism. The authors used a sol-gel route for the powder preparation, and they were able to grow single crystals of KNN as big as 3 mm by sintering for 2 h at 950 °C.

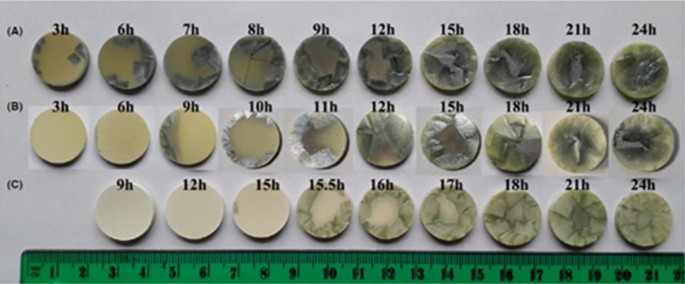

Later on, Jiang et al. [ 57 ] showed in their study on KNN that it is possible to obtain a high-quality single crystal KNN of perovskite structure (11 × 9 × 3) mm 3 via the SFSSCG method through a relatively simple and low cost route. They observed that single crystal grains tend to form a structure with a self-assembled arrangement, with preferred orientation and layer stacking along the growth direction. They also performed a systematic study on the effects of sintering aid content (LiBiO 3 ), as well as sintering time and temperature on crystal growth. Figure 10 presents the results of their systematical study on crystal growth kinetics, where the growth of large grains was triggered under certain conditions. In the same year, Ahn et al. [ 58 ] reported self-growth of a centimeter-sized single crystal of 0.985(K 1/2 Na 1/2 )NbO 3 –0.015Ba(Cu 1/3 Nb 2/3 )O 3 (KNN–BCuN) by the SFSSCG method. The authors prepared a KNN polycrystalline powder in a conventional way, with the addition of Ba 2+ ions aimed to compensate for the loss of Na + ions due to Na 2 O volatilization during the liquid phase sintering, and CuO as sintering aid which is known to form a liquid phase at high temperatures. The authors were able to observe the self-growth of giant grains which were single crystals, as shown in Fig. 11 . They also stressed the importance of the CuO addition because it had a vital role in the stimulation of AGG. Although the giant single crystal of KNN–BCuN contained a significant number of pores, it showed excellent piezoelectric properties and was found to be a promising candidate for piezoelectric sensors and energy harvesting devices. Another important benefit presented by the authors was that the SFSSCG method was approximately 100 times faster than the SSCG method.

KNN samples with LiBiO 3 sintering aid, sintered under different temperature and time regimes [ 57 ]

Variation of sizes of KNN–BCuN single crystals with sintering temperature grown by seed-free SSCG method [ 58 ]

In the years following, there have been many different reports on single crystal growth in KNN-based ceramics by using the SFSSCG method in which the authors achieved improvements in piezoelectric properties of the grown crystals. Yang et al. [ 59 ] reported improved piezoelectric properties in their self-grown single crystal of (K 0.45 Na 0.55 ) 0.96 Li 0.04 NbO 3 . Another group reported CaZrO 3 -doped KNN-based single crystals [ 60 ] grown by the SFSSCG method, which showed improved piezoelectric and dielectric properties as well. In 2017, Hao et al. [ 61 ] reported their study on the effects of different ratios of sodium and potassium in KNN on the growth of the single crystal by the SFSSCG method. They summarized their results in a composition-temperature phase diagram at which they showed that the growth of the single crystal KNN is possible only in a very narrow range of Na/K ratios and temperatures.

In the most recent study, the group of authors who had already reported their study on KNN–BCuN ceramics [ 58 ], has now proposed a compositional design rule for the growth of large single crystals in KNN-based ceramics by the SFSSCG method [ 62 ]. They determined that the amount of Ba 2+ (donor ion) in the system had a significant role in AGG, and therefore on the growth of the single crystal. The authors came up with equations with which they were able to calculate, and in that way predict, how much of each ion is present or substituted in the system. Their calculations showed a good fit with the experimental data, so they were able to establish a rule for the design of the KNN-based single crystals based on their equations.

Later on, Jiang et al. [ 41 ] proposed a crystal growth method in their latest work which could qualitatively explain the SFSSCG mechanism in KNN-based ceramics. As they pointed out, the AGG at which the SFSSCG model is based on should no longer be regarded as abnormal, but normal since the process of grain growth is now understood much better, and in that way better controlled, at least in case of KNN-based materials.

NBT-based lead-free single crystals

Another group of promising lead-free piezoelectric ceramics which were found to be able to be converted to single crystal materials are (Na 1/2 Bi 1/2 )TiO 3 or NBT-based materials. These materials may be presented with a general formula (Na 1/2 Bi 1/2 )TiO 3 –BaTiO 3 –(K 1/2 Na 1/2 )NbO 3 or shorter NBT–BT–KNN. NBT–BT–KNN single crystals are traditionally fabricated via the flux or the Bridgman method, but both methods introduce the difficulties of getting the crystals to have uniform chemical compositions due to the volatility of Na- and Bi-oxides. This further creates difficulties in obtaining single crystalline NBT–BT–KNN with desired piezoelectric properties. The SSCG method, therefore, appeared as a promising technique for obtaining such single crystal materials.

In one of the earliest reported studies on the application of the SSCG method for the conversion of polycrystalline NBT‒BT‒KNN to single crystal, Park et al. [ 63 ] successfully grew an NBT–BT–KNN single crystal from conventionally prepared ceramic powder. In their experimental work, this group used a SrTiO 3 single crystal seed of <110> orientation embedded in a ceramic powder to initiate single crystal growth during a 50-h annealing period at a temperature of 800 °C. The grown single crystal exhibited good piezoelectric properties which were comparable to those of other lead-free single crystals. The same group of authors continued their research on the same material [ 64 ] and 2 years later reported their finding that the KNN content in NBT–BT–KNN had a significant effect on the piezoelectric properties of NBT–BT–KNN single crystals. Along with that, they were able to demonstrate that the SSCG method was a prospective method for growth of NBT–BT–KNN single crystals with high performance, which could replace Pb(Zr,Ti)O 3 for actuator applications. In the same year, the aforementioned group of authors presented their results on NBT–BT–KNN single crystals by seeding with a SrTiO 3 single crystal [ 65 ]. They fabricated a highly dense NBT–BT–KNN single crystal with significant improvements in its piezoelectric properties, which were higher than that of any previously reported ceramics or single crystal. The high relative density (96.6%) of a grown crystal was achieved by creating a layered structure which was composed of pre-sintered ceramic pellets between which a seed crystal was positioned, followed by a 30-h annealing period at 900 °C in air. This method enabled the authors to fabricate a single crystal which had a notably smaller number of pores, which typically remain entrapped in the powder compact.

Another group of NBT-based piezoelectric single crystals which will be covered by this review pertains to the solid solution of (Na 1/2 Bi 1/2 )TiO 3 (NBT) with alkali earth perovskite-type materials (CaTiO 3 , SrTiO 3 and BaTiO 3 ).

The solid solution system (Na 1/2 Bi 1/2 )TiO 3 –BaTiO 3 (NBT–BT) was found to be a promising environmentally friendly, lead-free piezoelectric material. In the study on NBT–BT single crystals obtained by the SSCG method, Moon et al. [ 66 ] demonstrated that the common problem associated with the insufficient AGG, which is important for the growth of single crystals of practical sizes, can be overcome. They fabricated NBT–BT single crystals by using a SrTiO 3 seed crystal embedded in the ceramic powder compact, which had a certain degree of porosity and density inhomogeneity, but still exhibited good piezoelectric properties. In 2016, Gürbüz et al. [ 67 ] reported their comparative study between NBT–BT single crystals grown by SSCG, which included both the conventional and spark plasma sintering (SPS) methods. The authors demonstrated a significant difference in porosity between the single crystals obtained using these two sintering techniques. They achieved 99% of the theoretical density of the grown single crystal for the sample sintered by SPS for 5 min at 950 °C, while conventional sintering in air for 2 h at 1130 °C produced a single crystal with 96% of the relative density. The same result was in favor to SPS sintering when the dielectric properties were measured, which demonstrated that SPS might be an efficient technique for fabrication of NBT-based single crystals by the SSCG method, providing high relative densities and low alkaline evaporation.

In literature, reports can also be found on NBT-based single crystals grown by the SSCG technique which used other alkali earth perovskites, such as CaTiO 3 and SrTiO 3 . For example, in 2016, Lee et al. [ 68 ] reported for the first time a single crystal 0.8(Na 1/2 Bi 1/2 )TiO 3 –0.2SrTiO 3 grown by the SSCG method, which was grown from the SrTiO 3 single crystal as a seed crystal. The grown single crystal exhibited high porosity. Le et al. [ 69 ] afterward reported growth of 0.75(Na 1/2 Bi 1/2 )TiO 3 –0.25SrTiO 3 single crystal using the same approach. They investigated the dependence of growth of the single crystal and matrix grains on sintering time and temperature, and showed that the results could be explained with the mixed control mechanism of microstructural evolution [ 23 ].

Later on and for the first time ever, a different group of authors reported on a fabricated 0.96(Na 1/2 Bi 1/2 )TiO 3 –0.04CaTiO 3 single crystal [ 70 ] via conversion of the polycrystalline powder matrix to a single crystal, in presence of SrTiO 3 as a seed crystal. The grown single crystal showed improved ferroelectric and piezoelectric properties compared to its polycrystalline ceramic counterpart.

Ferroelectric materials

Ferroelectric oxides are a class of perovskite-type materials which exhibit spontaneous electrical polarization that can be oriented in the presence of an external electric field. Also, these materials possess other properties such as piezoelectricity and pyroelectricity and may have large dielectric constants which are important for actuator and sensor applications. BaTiO 3 and Ba(Zr x Ti 1− x )O 3 or Ba(Zr,Ti)O 3 (BZT) are some of the most important ferroelectric oxides and, thus, will be covered in this review.

BaTiO 3 single crystals