Welding and Fabrication Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business ideas » Construction & Engineering Industry » Welding and Fabrication

Are you about starting a welding and fabrication business ? If YES, here is a complete sample welding and fabrication business plan template & feasibility report you can use for FREE .

When we look around where we work or reside, we will sure note items that you that was produced by a wielder or has been through a welding process. This is why the services of skilled wielder will always be needed and the craft will keep getting attractive.

It is believed that the wielding industry is one industry that shows a substantial return in your investment at every turn and moment. When starting a wielding business, you go need to go for welding training. You also need to be certified, and to get certified, you need to undergo certain trainings in welding.

A Sample Welding and Fabrication Business Plan Template

1. industry overview.

This ever blooming industry seems to be growing the fastest with recent years showing maximum growth. The welding industry has been approximately stated to grow at the very least 6% per year. Conventional electric arc welding equipment and filler metals represent over two-thirds of this total.

This industry has many segments and each segment of the industry and each welding process have its own growth patterns noted after accurate research. It’s important to note that Welding is now the universally accepted method of permanently joining all metals.

The welding industry is considered a mature industry but it is still a growing industry from different perspectives. The true impact of welding on the metalworking industry should be measured in the value of the parts produced by welding, the amount of money saved by the use of welding over other metal fabrication processes, and in the value of products made possible by welding.

Facts on ground has gone a long way to show the growth of the welding equipment and materials industry, which also serves as an indication of the projected growth for the future.

2. Executive Summary

Sonic Welders (SW) is an established wielding and fabrication business that is engaged in the production of aluminium boat docks that will suit and satisfy the diverse designs and concepts of the customer. We at SW are very much dedicated to providing the highest quality workmanship, reaching the agreed delivery dates, and actualizing the custom work exactly in accordance with the customer’s concept a d astonishing designs.

Our focus at SW is to find out who our future target clients are and understand our marketing strategy, and to expand our operations and marketing so it can substantially increase profitability while also serving the united states of America. Sonic Welder will be established in Thunder Bay, Wisconsin.

Marquette is the county seat of Marquette County and it’s in the upper peninsula of Lake Superior. SW is a business built or established as a sole proprietorship and is owned by Nathan Cardozo who has over 27 years of experience in the wielding and fabrication industry and has built a reputation of excellence and quality work that is very important in the industry.

We at SW plan to manufacture and sell aluminium boat docks and also perform other welding and fabrication services for truck bodies and commercial equipment. We at SW plan to gain our market share in the following target markets: Marinas in Marquette, Lake Superior Upper Peninsula (boat owners), Commercial Customers, Agricultural Entities, and Local Municipalities.

3. Our Products and Services

We at SW primarily wield, fabricate and sell aluminium boat dock in the Marquette area of upstate Wisconsin. We also plan to fabricate and repair truck bodies, and perform aluminium repair jobs. All unused scrap metals will also be recycled by Sonic Welders.

The first revenue stream is extremely important to us at SW as our bottom line is to make sure that the welding services we render are in continued demand despite deleterious changes in the general economy. We also believe that this revenue stream has very high margins and will make sure that the profitability of our enterprise on a monthly basis.

We at SW also plan to raise revenues through the distribution of welding supplies, gasses, and related items that will be bought primarily by local contractors (and also individuals that do their own welding). We at SW expect gross margins of 50% on all welding products sold in our company.

4. Our Mission and Vision Statement

- Our vision at SW is to become the recognized local leader in our targeted market for all wielding and fabrication activities.

- Our mission at SW is to build the best quality product, supply over the top service at installation, and provide exceptional customer service after the sale of the product.

Our Business Structure

It is very important to note that the backbone and founder of SW is Nathan Cardozo. Nathan Cardozo got a dual degree from UC Berkeley, one in business, the second in mechanical engineering . We believe that Nathan Cardozo chose these fields because of his interest in parts construction and general engineering theories and application.

Nathan also believed that it would be very crucial for him to have a business background for possible future application. Sonic Welders will be run solely for now by Nathan Cardozo. He will be in charge of product procurement, order taking, customer service, and assorted other activities.

But as he moves to grow the business, by travelling to the trade shows, doing all necessary things as well as ramping up sales to accommodate the distributor sales, Nathan Cardozo will employ workers that will cover a wide range of services for the company. These workers include;

Chief Executive Officer

Service and Production Supervisor

Operations Manager

- Sales and Marketing Executive

- Welding and Fabrication Engineers / Technicians

Client Service Executive

5. Job Roles and Responsibilities

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counselling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results; developing incentives; developing a climate for offering information and opinions; providing educational opportunities.

- In charge of providing direction for the business

- Creating, communicating, and implementing the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- In charge of signing checks and documents on behalf of the company

- Evaluates the success of the organization

- Serve as project manager of the organization; works directly with employees

- Develops strategic plan by studying new automobile technological, and financial opportunities; presenting assumptions; recommending objectives.

- Accomplishes subsidiary objectives by establishing plans, budgets, and results measurements; allocating resources; reviewing progress; making mid-course corrections.

- Coordinates efforts by establishing procurement, production, marketing, field, and technical services policies and practices; coordinating actions with corporate staff.

- Builds company image by collaborating with customers, government, community organizations, and employees; enforcing ethical business practices.

- Maintains quality service by establishing and enforcing organization standards.

- Maintains professional and technical knowledge by attending educational workshops; reviewing professional publications; establishing personal networks; benchmarking state-of-the-art practices; participating in professional societies.

- Make certain that the service and production department perform efficiently, coordinate employee efforts, and facilitate communications between management and computer repairs and maintenance engineers and technicians

- Make sure s that the organization works in line with international best practices.

- In charge of overseeing the smooth running of HR and administrative tasks for the organization

- Defining job positions for recruitment and managing interviewing process

- Carrying out staff induction for new team members

- In charge of training, evaluation and assessment of employees

- In charge of arranging travel, meetings and appointments

- Oversee the smooth running of the daily office and factory activities.

Sales and Marketing Manage r

- Manage external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Model demographic information and analyse the volumes of transactional data generated by customer

- Identifies development opportunities; follows up on development leads and contacts; participates in the structuring and financing of projects; assures the completion of development projects.

- Writing winning proposal documents, negotiate fees and rates in line with organizations’ policy

- In charge of handling business research, market surveys and feasibility studies for clients

- In charge of supervising implementation, advocate for the customer’s needs, and communicate with clients

- Develop, execute and evaluate new plans for expanding increase sales

- Create new markets cum businesses for the organization

- Empower and motivates the sales team to meet and surpass agreed targets

Accountant / Cashier

- In charge of preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports; analyses financial feasibility for the most complex proposed projects; conducts market research to forecast trends and business conditions.

- In charge of financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting for one or more properties.

- In charge of developing and managing financial systems and policies

- In charge of administering payrolls

- Ensuring compliance with taxation legislation

- Handles all financial transactions for the business

- Serves as internal auditor for the business

Welding and Fabrication Engineers and Technicians

- In charge of developing welding and fabrication techniques, procedures, and application of welding equipment to problems involving fabrication of metals, utilizing knowledge of production specifications, properties and characteristics of metals and metal alloys, and engineering principles: Conducts research and development investigations to develop and test new fabrication processes and procedures, improve existing or develop new welding equipment, develop new or modify current welding methods, techniques, and procedures, discover new patterns of welding phenomena, or to correlate and substantiate hypotheses.

- Tasked with preparing technical reports as result of research and development and preventive maintenance investigations.

- Builds welding procedures to guide production and welding personnel relating to specification restrictions, material processes, pre- and post-heating requirements which involve use of complex alloys, unusual fabrication methods, welding of critical joints, and complex post heating requirements.

- In charge of evaluating new developments in welding field for possible application to current welding problems or production processes.

- Responsible for directing and coordinating technical personnel in performing inspections to ensure workers’ compliance with established welding procedures, restrictions, and standards; in testing welds for conformance with national code requirements; or testing welding personnel for certification.

- In charge of contacting personnel of other agencies, engineering personnel or clients to exchange ideas, information, or offer technical advice concerning welding matters.

- May perform experimental welding to evaluate new equipment, techniques, and materials.

- Welcomes clients and potential clients by greeting them in person or on the telephone; answering or directing inquiries.

- Make sure s that all contacts with clients (e-mail, walk-In centre, SMS or phone) provides the client with a personalized customer service experience of the highest level

- Through interaction with clients on the phone, uses every opportunity to build client’s interest in the company’s products and services

- Serves as a auto parts sell attendant

- Manages administrative duties assigned by the creative director in an effective and timely manner

- Consistently stays abreast of any new information on the organizations’ products, promotional campaigns etc. to Make sure accurate and helpful information is supplied to clients when they make enquiries

6. SWOT Analysis

We at SW believe will have the plan and capabilities to take over the welding industry. We hope to build and maintain an extensive shop which can handle all welding and fabrication issues. We have adequate plans to make our business the best in the industry, which is why we contacted Mandolin Business Consultants to do our SWOT Analysis for us.

Mandolin Business Consultants are known for the experience and agility they posses in terms of business consulting and analysis.

They were very thorough with their dealings and outlined below is a summary of the SWOT Analysis they conducted for us. The following SWOT analysis captures the key strengths and weaknesses within our company, and describes the opportunities and threats facing us at SW.

- Outstanding reputation.

- Quality – we at SW will guarantee all of our work, using the highest quality materials available and the most experienced fabricator available.

- Customer Care – we at SW will go extra time to make sure the customer is satisfied with the service provided.

- Experience – Over 27 years in the construction business, Nathan Cardozo is a talented, experienced fabricator, with a strong work ethic.

- Our weaknesses at SW come from the lack of funding to grow the business. Grant money will be used to purchase equipment, company expansion, create website, advertise, and hire an employee.

Opportunities

- Growing market with a significant percentage of our target market still not knowing we exist.

- Strategic alliances offering sources for referrals and joint marketing activities to extend our reach.

- Increasing sales opportunities beyond our “lake area” to include the many other lakes in the [STATE] area.

- The only obstacle to our success at SW would be further downswings in the economy of the world

7. MARKET ANALYSIS

- Market Trend

After due research, it is believed that semiautomatic welding will greatly increase, machine and automatic welding will increase modestly, but manual welding is decreasing at least as a percentage of the total. Furthermore, it is now evident that the following must be considered with regard to the future of welding:

- There will be continuing need to reduce manufacturing costs and to improve productivity, since wage rates for the people in manufacturing industries will keep on increasing, the cost of metals for producing weld metals and filler metals will also continue to be more expensive, and energy and fuel costs will increase and shortages may occur.

- Also there will be a continuing trend towards the use of higher-strength materials, particularly in the steels and lighter-weight materials.

- There will be more use of welding by manufacturing industries, probably decreasing the use of castings.

- There will be a trend towards higher levels of reliability and higher-quality requirements.

- The trend towards automatic welding and automation in welding will accelerate.

Productivity in this very industry is considered the amount of welding that can be done by a welder in a day. Productivity can be determined by several factors, the most important of which is the operator factor or duty cycle. Operator factor for a welder is the number of minutes per eight-hour period that is spent actually welding.

The different methods of welding have different average duty cycles. Manual welding has the lowest operator factor with semiautomatic welding approximately double and machine welding the next highest, with automatic welding approaching 100%.

Efforts will be made to utilize those processes that have the highest-duty cycles. The expected trend will be away from manual welding towards semiautomatic welding and to machine or automatic welding when possible.

Another factor affecting productivity of welders relates to the deposition rate of the welding process. The higher current processes have the highest deposition rates, thus the submerged arc welding process and the electro slag welding process will remain important as costs must be reduced.

8. Our Target Market

We at SW hope to focus on our ability to complete any project with the required equipment by having all the necessary tools.

Sonic Welders market segmentation scheme is fairly straightforward, and focuses on the target markets of the lake marinas within the banks of Lake Superior, local municipality contracts , agricultural entities, and commercial and residential customers.

We also understand that our prospective customers will prefer a certain quality of work and timeliness and it is our duty at SW to deliver on their expectations. We at SW know that there will always be a need for fabrication companies.

We understand that the customers within the fabrication industry want exceptional workmanship and affordable rates. We believe that our prospective customers will appreciate the quality service that we are hoping to offer, as well as the knowledgeable and experience of our owner.

We believe that these customers have the option to go elsewhere, but they understand that giving their business to SW will be of more advantage to them because we at SW deliver the dedication that they desire. We know Boat dock fabrication is seasonal but with aggressive marketing efforts could expand company operations and reach many more markets along the lakes. Our target market may include;

- Marinas around the mighty Lake

- Agricultural entities in Marquette

- Local Municipalities

Our competitive advantage

It is a known fact that Welding will continue to be a highly efficient and economical method for maintaining structural integrity when joining metals and non-metals, including plastics and composites. We also believe that the welding industry will continue to maintain a strong reputation for producing reliable and cost-effective welded components in the global market.

We have also noted after extensive research that the industry due to a growing need for welded components and a decline in skilled workforce is focused on continual design advancements in welding machines (particularly welding automation) to further enhance efficiency.

The competition in this industry is becoming heavy and unbelievable, which is why we are making all plans efficiently to make sure we take over the market.

We at SW have a strong competitive edge in the industry due to the many fabrication services we hope to offer. We hope that by building a business based on satisfying clients, SW simultaneously build defences against competition. We at SW plan to continue helping clients understand what we offer them and why they need it.

We at SW also plan to become a leading provider of fabrication services in the local area. We believe that to achieve this, we have to invest in many ways that will pay off in competitive advantages for our customers, by pre-job conferencing upon request and assisting in the technical or conceptual design.

9. SALES AND MARKETING STRATEGY

- Sources of Income

It is very important to note that the US fabricated metal parts manufacturing industry includes about 55,000 companies with about 0 billion in combined annual revenue. Major companies in specialty segments include Ball Corporation, Flowserve, Mueller Industries, Snap-On, and The Timken Company.

We believe that because of the special manufacturing processes involved for individual parts, most companies make a limited range of products.

We also have noted after extensive research that the industry as a whole is fragmented: the largest 50 companies account for about 20 percent of revenue. But concentration can be high in industry segments such as boiler, cutlery, metal can, and spring manufacturing.

We at SW plan to get revenues by wielding, fabricating and selling aluminium boat dock in the Marquette area of upstate Wisconsin. We also plan to get funds by fabricating and repairing truck bodies, and performing aluminium repair jobs.

All unused scrap metals will also be recycled by us. The first revenue stream is extremely important to us at SW as our bottom line is to make sure that the welding services we render are in continued demand despite deleterious changes in the general economy.

We also believe that this revenue stream has very high margins and will make sure that the profitability of our enterprise on a monthly basis.

10. Sales Forecast

Our primary ethics at SW is to maintain an excellent customer relation skills and work ethic; these skills we believe will be useful in making customers comfortable in believing us to provide their construction services. We believe that maintaining our customer’s satisfaction is an implicit part of building a relationship that will encourage repeat business.

Our sales projections at SW are based on our promising foundation, our planned increase investment in advertising for our business and future expansion will make us even more appealing to prospective customers. Our Sales forecast for the coming three years in as follows;

- First Year-: $650,000

- Second Year-: $1,100,000

- Third Year-: $2,452,000

- Marketing Strategy and Sales strategy

We at SW totally understand that satisfied customers will aid our business by referring our company to other clients who need our services. We at SW plan to serve the metal fabrication market segment. Our specific choice of target markets at SW is based on an in-depth understanding of our prospective customer’s needs.

We believe that our skills and capabilities will allow us to very well compete and develop our reputation within our business area. This is the reason why we believe that obtaining grant funding and developing a marketing strategy will improve our profitability levels and help us in building a strong customer base.

We at SW plan to use a direct sales force and relationship selling to reach its target markets. These channels are most appropriate because of time to market, reduced capital requirements, and fast access to established distribution channels.

We also plan to advertise in Yellow Pages and local newspapers, and create a website with information, construction background, and contact information will be available online. References to the website will be mentioned in all other forms of advertising once the website is in effect.

SW is a member of the Marquette Lake Association and will obtain a mailing list for potential customers. But we believe that our marketing budget will allow our employed marketing firm the leverage to push us to the top.

11. Publicity and Advertising Strategy

We at SW plan to use email marketing campaigns as an outreach to our prospective customers. We all know that technology that incorporates video with email and offers very powerful, robust and dynamic features. Another advantage is in communicating through the use of streaming video embedded within the email.

We at SW believe that the use of this technology will give us a strong competitive edge and outreach to the community. We at SW are also planning to incorporate an email drip campaign with video into our marketing efforts.

We believe that this technology will more effectively market to our customer and potential customer base. We understand that it is cost effective (averaging about $99 per month), especially when compared to the $1,000’s spent on print advertising, mailing and postage.

We believe that the built-in analytics provide immediate feedback as to the campaigns effectiveness and who actually viewed the message. We also hope that the Auto responders with a specific message can be utilized as an immediate follow-up tool.

It is important to note that we at SW hope that this new email marketing campaign technology will serve to position us to achieve and sustain name recognition in front of our current market within the local community.

We believe that this type of marketing is cost effective and efficient. The first thing most of us do every day is check our email in-box. It is also worthwhile to state that we at SW are currently unaware of any of our competitors incorporating the use of this technology within their operation.

12. Our Pricing Strategy

We at SW know that we are in a purely competitive industry where each business must be a price taker. Meaning that a business that has no ability to affect the market price of its services, regardless of how much work it does is destined for a meltdown.

Therefore, putting it, that marginal revenue (the revenue incurred by producing or servicing one more unit) is equal to the price charged. Furthermore, because the demand curve is essentially horizontal, we at SW plan to at total capacity without affecting the price in the market.

This means that we at SW must strive or look to charge our clients at the market price (or lower). We believe that the price we charge will depend on the workload and duration of the said work, and we understand that as long as marginal costs do not surpass revenues, the method to increase short-run profits is to service automobiles at maximum capacity.

- Payment Options

We at SW after extensive research understand that payment options are the forces that bring any business closer to the heart of the people, and we hope to make use of that extensively. We will be bringing payment options that are unique and will make the payment for the service we offer very easy for our customers.

- Payment by via bank transfer

- Payment via POS machine

- Payment via online bank transfer

- Payment via mobile money

- Payment with cash

To provide all these outstanding services, we have partnered with a renowned bank in the country and we hope to make use of that relationship. Our bank account numbers will be made available on our website and promotional materials so that it will be easier for clients to make payments when necessary.

13. Startup Expenditure (Budget)

It is very important to note that no matter how breath taking your ideas and goals might be or how attractive your business plan might be, without proper and enough financing your ideas are just like water poured on a rock.

It is a known fact that in every business enterprise fund is a big ingredient that can move a business to the limelight and without a detailed business plan; a business won’t be able to land substantial funds from prospective investors. We have analysed the market and have decided on how we plan to spend our start up fund.

These are the key areas where we will spend our start – up capital on;

- Business incorporation fees in the United States of America will cost – $750.

- The budget for Liability insurance, permits and license will cost – $3,500

- Acquiring a work facility that can accommodate a good number of cars per time for at least 6 months (Re – Construction of the facility inclusive) will cost – $100,000.

- The amount required to purchase the needed tool box and repair equipment – $25,000

- Equipping the office (computers, printers, projectors, markers, servers / internet facility, furniture, telephones, filing cabinets, and electronics) will cost – $30,000

- Amount required to purchase the needed software applications to run our business – $3,500

- Launching an official Website will cost – $500

- Amount need to pay bills and staff members for at least 2 to 3 months – $70,000

- Additional Expenditure such as Business cards, Signage, Adverts and Promotions will cost – $5,000

From our detailed cost analysis above, we will be needing approximately two hundred and fifty dollars ( $250,000 ) to start SW. Everything has been put in place and every fact made sure of, that is to enable us achieve our goal and objectives.

Generating Funding / Start up Capital for Sonic Welders

Sonic Welders (SW) is an established wielding and fabrication business owned by Nathan Cardozo that is engaged in the production of aluminium boat docks that will suit and satisfy the diverse designs and concepts of the customer. The business will be funded by him until we decide to accept investors or partners. Ways we hope to raise our start up capital may include;

- Generate part of the start – up capital from personal savings

- Generate part of the start – up capital from friends and other extended family members

- Generate part of the capital from the bank (loan facility).

Note: Nathan Cardozo has been able to raise $100,000 ( $70,000 from personal savings and $30,000 as soft loans from family and friends ) and we are at the final stages of obtaining a loan facility of $100,000. We have verified all the necessary procedures to actualize or get our start up cost.

14. Sustainability and Expansion Strategy

We at SW understand that our business being medium in nature requires a simple organizational structure. We believe that the implementation of this organizational form calls for Nathan Cardozo to make all of the major management decisions in addition to monitoring all other business activities.

Nathan Cardozo started working in the metal fabrication industry after working in the salt mines for several years and now brings over 27 years of experience to the success of the Company. Our management philosophy at SW is based on responsibility and mutual respect.

We believe that SW will maintain an environment and structure that will bring about productivity and respect for customers and fellow employees. At Sonic Welders, everybody is considered as an individual and we strive to the very last point to respect their dignity and recognize their merit.

We believe that our employees will be encouraged to have a sense of security and pride in their jobs. We will also afford equal opportunity for employment, development, and advancement for those qualified. Our employees at SW will be committed to:

- Afford a safe work environment to protect employees, the employees of customers and subcontractors, and the public.

- We will also supply safe products for customers.

- We will also without setbacks keep on improving the company’s safety program to reduce the risk of accidents and occupational illness in a changing work environment.

- We will advice our employees to participate in accident prevention programs and take personal responsibility for their own and their co-workers’ health and safety.

- Regulatory compliance and contribution to high safety standards for our industry.

- Monitoring workplaces, enforcing safe work practices, and communicating the company’s safety performance to employees and other stakeholders.

Checklist/Milestone

- Business Name Availability Check: Completed

- Business Incorporation: Completed

- Opening of Corporate Bank Accounts various banks in the United States: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of All form of Insurance for the Business: Completed

- Conducting Feasibility Studies: Completed

- Leasing, renovating and equipping our facility: Completed

- Generating part of the start – up capital from the founder: Completed

- Applications for Loan from our Bankers: In Progress

- Writing of Business Plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents: In Progress

- Design of The Company’s Logo: Completed

- Graphic Designs and Printing of Packaging Marketing / Promotional Materials: Completed

- Recruitment of employees: In Progress

- Purchase of the Needed software applications, furniture, office equipment, electronic appliances and facility facelift: In progress

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business (Business PR): In Progress

- Health and Safety and Fire Safety Arrangement: In Progress

- Establishing business relationship with banks, financial lending institutions, vendors and key players in the industry: In Progress

Related Posts:

- Dump Truck Business Plan [Sample Template]

- Home Remodeling Business Plan [Sample Template]

- Excavation Company Business Plan [Sample Template]

- Mobile Manufactured Home Business Plan [Sample Template]

- Engineering Consulting Business Plan [Sample Template]

How to Start a Welding Business

A welding business repairs, restores, and assists building metal-based items. Welding and fabrication services include flux core welding, aluminum welding, plasma cutting, metal fabrication, dump truck box repair, and more. A high-quality welding business can fix most things made out of metal, assisting numerous projects in the span of a year.

Learn how to start your own Welding Business and whether it is the right fit for you.

Ready to form your LLC? Check out the Top LLC Formation Services .

Start a welding business by following these 10 steps:

- Plan your Welding Business

- Form your Welding Business into a Legal Entity

- Register your Welding Business for Taxes

- Open a Business Bank Account & Credit Card

- Set up Accounting for your Welding Business

- Get the Necessary Permits & Licenses for your Welding Business

- Get Welding Business Insurance

- Define your Welding Business Brand

- Create your Welding Business Website

- Set up your Business Phone System

We have put together this simple guide to starting your welding business. These steps will ensure that your new business is well planned out, registered properly and legally compliant.

Exploring your options? Check out other small business ideas .

STEP 1: Plan your business

A clear plan is essential for success as an entrepreneur. It will help you map out the specifics of your business and discover some unknowns. A few important topics to consider are:

What will you name your business?

- What are the startup and ongoing costs?

- Who is your target market?

How much can you charge customers?

Luckily we have done a lot of this research for you.

Choosing the right name is important and challenging. If you don’t already have a name in mind, visit our How to Name a Business guide or get help brainstorming a name with our Welding Business Name Generator

If you operate a sole proprietorship , you might want to operate under a business name other than your own name. Visit our DBA guide to learn more.

When registering a business name , we recommend researching your business name by checking:

- Your state's business records

- Federal and state trademark records

- Social media platforms

- Web domain availability .

It's very important to secure your domain name before someone else does.

Want some help naming your welding business?

Business name generator, what are the costs involved in opening a welding business.

Startup costs sit around $10,000 to $50,000. These costs include a metal fabrication shop, which has a rent of about $3,000 per month. These costs also account for insurance, tools, electronics, mobile service options, and personal protection equipment. Minor equipment can be purchased for as little as $1,000, but you’ll need to expand your inventory as more projects are approached.

Read our welding business purchasing guide to learn about the materials and equipment you'll need to start a welding business, how much to budget, and where to make purchases.

What are the ongoing expenses for a welding business?

Employees will be paid between $45 and $65 per hour. Additionally, raw material will need to be purchased. Typically, this raw material will be marked up by about 50 percent when it’s used.

Who is the target market?

The best clients and customers are those with ongoing welding needs. While you can conduct single projects, you’re better off engaging clients who manage commercial machinery. Among your many clients, several will be incredibly profitable. The best jobs a welding business scan undertake are mega yacht repair, marine equipment fabrication, architectural iron modification, aircraft repair and remanufacturing, cruise ship service, and restaurant equipment repair.

Because commercial providers need to meet certain industry standards, they’re incredibly profitable. Welding clients can extend to farm equipment owners, other welding shops, silo tank providers, and even steel dairy equipment providers.

How does a welding business make money?

Most welding businesses make money by performing small projects. They can, however, make a lot of money by engaging long-term projects. Because a welding company’s best providers are normally marine equipment providers, a lot of service is needed to prevent rusting and water damage.

A welding company also makes money by making metal modifications and repairs. If a company’s machinery breaks, a welding business will be called to examine the surrounding problems. It may also contact a separate repair team—taking charge with metal repairs and needed fabrications, itself.

Welding services can be charged in two ways. First, they can be charged on a per-job basis. They can also be charged at an hourly rate. Typically, per-hour rates are between $30 and $70 per hour. A well-established welding company may offer higher prices for special jobs and work needs.

How much profit can a welding business make?

A well-established welding service provider can gain yearly profits of about $70,000. A highly successful welding business, meanwhile, can make six figures easily.

How can you make your business more profitable?

Every period of work time should be budgeted. A poorly drawn business plan is believed to be the number-one cause of welding business failure. Know what you can afford, and prioritize your customers. Don’t buy personal toys—welding equipment—before you need it. Focus on getting the business in the door, and find the best customers who need your services. From start-up independent jobs to multi billion-dollar contracts, you’ll need to be a good face-to-face negotiator.

Want a more guided approach? Access TRUiC's free Small Business Startup Guide - a step-by-step course for turning your business idea into reality. Get started today!

STEP 2: Form a legal entity

The most common business structure types are the sole proprietorship , partnership , limited liability company (LLC) , and corporation .

Establishing a legal business entity such as an LLC or corporation protects you from being held personally liable if your welding business is sued.

Form Your LLC

Read our Guide to Form Your Own LLC

Have a Professional Service Form your LLC for You

Two such reliable services:

You can form an LLC yourself and pay only the minimal state LLC costs or hire one of the Best LLC Services for a small, additional fee.

Recommended: You will need to elect a registered agent for your LLC. LLC formation packages usually include a free year of registered agent services . You can choose to hire a registered agent or act as your own.

STEP 3: Register for taxes

You will need to register for a variety of state and federal taxes before you can open for business.

In order to register for taxes you will need to apply for an EIN. It's really easy and free!

You can acquire your EIN through the IRS website . If you would like to learn more about EINs, read our article, What is an EIN?

There are specific state taxes that might apply to your business. Learn more about state sales tax and franchise taxes in our state sales tax guides.

STEP 4: Open a business bank account & credit card

Using dedicated business banking and credit accounts is essential for personal asset protection.

When your personal and business accounts are mixed, your personal assets (your home, car, and other valuables) are at risk in the event your business is sued. In business law, this is referred to as piercing your corporate veil .

Open a business bank account

Besides being a requirement when applying for business loans, opening a business bank account:

- Separates your personal assets from your company's assets, which is necessary for personal asset protection.

- Makes accounting and tax filing easier.

Recommended: Read our Best Banks for Small Business review to find the best national bank or credit union.

Get a business credit card

Getting a business credit card helps you:

- Separate personal and business expenses by putting your business' expenses all in one place.

- Build your company's credit history , which can be useful to raise money later on.

Recommended: Apply for an easy approval business credit card from BILL and build your business credit quickly.

STEP 5: Set up business accounting

Recording your various expenses and sources of income is critical to understanding the financial performance of your business. Keeping accurate and detailed accounts also greatly simplifies your annual tax filing.

Make LLC accounting easy with our LLC Expenses Cheat Sheet.

STEP 6: Obtain necessary permits and licenses

Failure to acquire necessary permits and licenses can result in hefty fines, or even cause your business to be shut down.

Federal Business Licensing Requirements

Certain state permits and licenses may be needed to operate a welding business. Learn more about licensing requirements in your state by visiting SBA’s reference to state licenses and permits .

State & Local Business Licensing Requirements

Certain state permits and licenses may be needed to operate a welding business business. Learn more about licensing requirements in your state by visiting SBA’s reference to state licenses and permits .

Services Contract

In business where services are provided on an extended basis, a services contract is often put in place outlining terms and conditions of service.

Welding businesses should require clients to sign a services agreement before starting a new project. This agreement should clarify client expectations and minimize risk of legal disputes by setting out payment terms and conditions, and service level expectations. An example of a service contract can be found here .

Labor safety requirements

It is important to comply with all Occupational Safety and Health Administration requirements .

Relevant requirements include:

- Employee injury report

- Safety signage

Certificate of Occupancy

Businesses operating out of a physical location typically require a Certificate of Occupancy (CO). A CO confirms that all building codes, zoning laws and government regulations have been met.

- If you plan to lease a location :

- It is generally the landlord’s responsibility to obtain a CO.

- Before leasing, confirm that your landlord has or can obtain a valid CO that is applicable to a welding business

- After a major renovation, a new CO often needs to be issued. If your place of business will be renovated before opening, it is recommended to include language in your lease agreement stating that lease payments will not commence until a valid CO is issued.

- If you plan to purchase or build a location :

- You will be responsible for obtaining a valid CO from a local government authority.

- Review all building codes and zoning requirements for your business’ location to ensure your welding business will be in compliance and able to obtain a CO.

STEP 7: Get business insurance

Just as with licenses and permits, your business needs insurance in order to operate safely and lawfully. Business Insurance protects your company’s financial wellbeing in the event of a covered loss.

There are several types of insurance policies created for different types of businesses with different risks. If you’re unsure of the types of risks that your business may face, begin with General Liability Insurance . This is the most common coverage that small businesses need, so it’s a great place to start for your business.

Another notable insurance policy that many businesses need is Workers’ Compensation Insurance . If your business will have employees, it’s a good chance that your state will require you to carry Workers' Compensation Coverage.

FInd out what types of insurance your Welding Business needs and how much it will cost you by reading our guide Business Insurance for Welding Business.

STEP 8: Define your brand

Your brand is what your company stands for, as well as how your business is perceived by the public. A strong brand will help your business stand out from competitors.

If you aren't feeling confident about designing your small business logo, then check out our Design Guides for Beginners , we'll give you helpful tips and advice for creating the best unique logo for your business.

Recommended : Get a logo using Truic's free logo Generator no email or sign up required, or use a Premium Logo Maker .

If you already have a logo, you can also add it to a QR code with our Free QR Code Generator . Choose from 13 QR code types to create a code for your business cards and publications, or to help spread awareness for your new website.

How to promote & market a welding business

Market directly to businesses. While cold-calling tactics are difficult to pull off, you’ll need to become good at them to find high-quality clients. Market to any business related to marine services, and try to get hired by big companies. If they’re part of a business network, fish for opportunities there.

How to keep customers coming back

Hiring an ongoing welding service provider is a long-term commitment. For this reason, customer retention can be difficult to obtain but easy to maintain. Your best retention tool is to ensure high-quality, quick services. As with any contracting job, companies will stick to providers which ensure reliable services.

STEP 9: Create your business website

After defining your brand and creating your logo the next step is to create a website for your business .

While creating a website is an essential step, some may fear that it’s out of their reach because they don’t have any website-building experience. While this may have been a reasonable fear back in 2015, web technology has seen huge advancements in the past few years that makes the lives of small business owners much simpler.

Here are the main reasons why you shouldn’t delay building your website:

- All legitimate businesses have websites - full stop. The size or industry of your business does not matter when it comes to getting your business online.

- Social media accounts like Facebook pages or LinkedIn business profiles are not a replacement for a business website that you own.

- Website builder tools like the GoDaddy Website Builder have made creating a basic website extremely simple. You don’t need to hire a web developer or designer to create a website that you can be proud of.

Recommended : Get started today using our recommended website builder or check out our review of the Best Website Builders .

Other popular website builders are: WordPress , WIX , Weebly , Squarespace , and Shopify .

STEP 10: Set up your business phone system

Getting a phone set up for your business is one of the best ways to help keep your personal life and business life separate and private. That’s not the only benefit; it also helps you make your business more automated, gives your business legitimacy, and makes it easier for potential customers to find and contact you.

There are many services available to entrepreneurs who want to set up a business phone system. We’ve reviewed the top companies and rated them based on price, features, and ease of use. Check out our review of the Best Business Phone Systems 2023 to find the best phone service for your small business.

Recommended Business Phone Service: Phone.com

Phone.com is our top choice for small business phone numbers because of all the features it offers for small businesses and it's fair pricing.

Is this Business Right For You?

A welding business should be run by individuals who’re experienced in metalworking, welding, and fabrication. It’s a solid business plan for workers who love excavating projects, fixing mechanical items, and performing general maintenance. A lot of welding projects are custom, giving project managers a lot of control over the services performed. A high degree of investment takes place, too, making it a good business for individuals who enjoy completing ongoing repairs, installations, and upgrades.

Want to know if you are cut out to be an entrepreneur?

Take our Entrepreneurship Quiz to find out!

Entrepreneurship Quiz

What happens during a typical day at a welding business?

A welding business owner must perform a number of activities. Among the many responsibilities a welding business owner has, understanding local laws, sales needs, and self-starting requirements is important. Welders assist with dump truck box repair, aluminum tank restoration, blade welding, lift welding, silver brazing, and fabrication projects. Other activities include ongoing research, metal repair, plasma cutting, and machine maintenance.

As an owner, you’ll need to conduct research on local market needs, effective sales strategies, management, and finance. You’ll similarly need to protect your team’s tools from damage, maintaining a healthy supply of metal-cutting tools to ensure high-quality services.

What are some skills and experiences that will help you build a successful welding business?

The skills a welding business provider must have are numerous. First, you’ll need to be able to read blueprints quickly and easily. You’ll also need an awareness of safety standards. Concentration, customer service skills, a detail-oriented work ethic, good eyesight, knowledge of metallurgy, tool knowledge, dexterity, and in-depth knowledge of different welding techniques are also important.

A successful welding business can service a wide array of projects. They handle jobs quickly, and they’re capable of meeting a high variety of client needs. Lasting welding businesses are committed to their work, ensure all aspects are completed correctly and have a sharp eye for new potential.

What is the growth potential for a welding business?

Welding businesses have a lot of potential. They can either be a niche welding business or a general welding shop. Understandably, niche welding businesses have a tight market area. They’re able to grow quicker, as there is less competition.

General welding shops, meanwhile, face a lot of competition. However, they do have a lot of services available. If a general welding shop advertises correctly, it can offer fabrication services for most jobs, though it will need to advertise across multiple industries and have a wide range of services and equipment.

TRUiC's YouTube Channel

For fun informative videos about starting a business visit the TRUiC YouTube Channel or subscribe to view later.

Take the Next Step

Find a business mentor.

One of the greatest resources an entrepreneur can have is quality mentorship. As you start planning your business, connect with a free business resource near you to get the help you need.

Having a support network in place to turn to during tough times is a major factor of success for new business owners.

Learn from other business owners

Want to learn more about starting a business from entrepreneurs themselves? Visit Startup Savant’s startup founder series to gain entrepreneurial insights, lessons, and advice from founders themselves.

Resources to Help Women in Business

There are many resources out there specifically for women entrepreneurs. We’ve gathered necessary and useful information to help you succeed both professionally and personally:

If you’re a woman looking for some guidance in entrepreneurship, check out this great new series Women in Business created by the women of our partner Startup Savant.

What are some insider tips for jump starting a welding business?

Develop a business plan quickly. A lot of welders think business plans are a time-sink, but a solid business plan can help you map out your business’s needs and expenses.

How and when to build a team

Once you’re spending over 40 hours a week fabricating and welding, you’ll need to hire more employees. Working this much is a good sign, as it proves you’re becoming a successful business. As a business owner, however, you’ll need to manage between three and five additional workers with care. They depend on you for their financial survival, and they’re typically paid more than average employees.

Read our welding business hiring guide to learn about the different roles a welding business typically fills, how much to budget for employee salaries, and how to build your team exactly how you want it.

Useful Links

Truic resources.

- TRUiC's Welding Business Hiring Guide

- TRUiC's Welding Business Purchasing Guide

Industry Opportunities

- Get Certified By the American Welding Society

- Membership Opportunities with The Welding Society

- Become a Certified Member of The International Institute of Welding

Real World Examples

- Large Welding Company

- Local Welding Company

Further Reading

- Tips for Starting Your Welding Company

Have a Question? Leave a Comment!

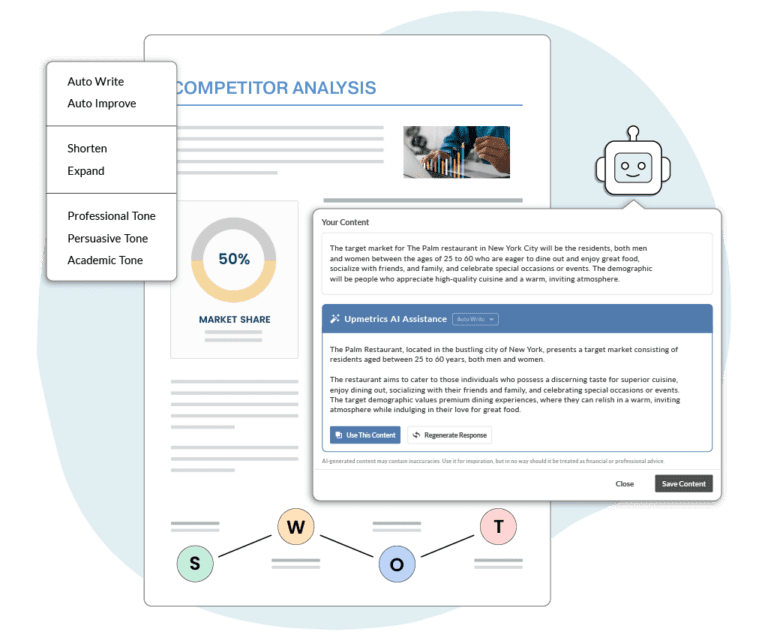

Upmetrics AI Assistant: Simplifying Business Planning through AI-Powered Insights. Learn How

Entrepreneurs & Small Business

Accelerators & Incubators

Business Consultants & Advisors

Educators & Business Schools

Students & Scholars

AI Business Plan Generator

Financial Forecasting

AI Assistance

Ai pitch deck generator

Strategic Planning

See How Upmetrics Works →

- Sample Plans

- WHY UPMETRICS?

Customers Success Stories

Business Plan Course

Small Business Tools

Strategic Canvas Templates

E-books, Guides & More

- Sample Business Plans

- Construction, Architecture & Engineering

Welding Business Plan

Free Business Plan Template

Download our free business plan template now and pave the way to success. Let’s turn your vision into an actionable strategy!

- Fill in the blanks – Outline

- Financial Tables

How to Write A Welding Business Plan?

Writing a welding business plan is a crucial step toward the success of your business. Here are the key steps to consider when writing a business plan:

1. Executive Summary

An executive summary is the first section planned to offer an overview of the entire business plan. However, it is written after the entire business plan is ready and summarizes each section of your plan.

Here are a few key components to include in your executive summary:

Introduce your Business:

Start your executive summary by briefly introducing your business to your readers.

Market Opportunity:

Welding services:.

Highlight the welding services you offer your clients. The USPs and differentiators you offer are always a plus.

Marketing & Sales Strategies:

Financial highlights:, call to action:.

Ensure your executive summary is clear, concise, easy to understand, and jargon-free.

Say goodbye to boring templates

Build your business plan faster and easier with AI

Plans starting from $7/month

2. Business Overview

The business overview section of your business plan offers detailed information about your company. The details you add will depend on how important they are to your business. Yet, business name, location, business history, and future goals are some of the foundational elements you must consider adding to this section:

Business Description:

Describe your business in this section by providing all the basic information:

Describe what kind of welding company you run and the name of it. You may specialize in one of the following welding businesses:

- General welding services

- Aluminum welding

- Mobile welding

- Specialty welding services

- Heavy steel fabricating

- Describe the legal structure of your welding company, whether it is a sole proprietorship, LLC, partnership, or others.Explain where your business is located and why you selected the place.

Mission Statement:

Business history:.

If you’re an established welding service provider, briefly describe your business history, like—when it was founded, how it evolved over time, etc.

Future Goals

This section should provide a thorough understanding of your business, its history, and its future plans. Keep this section engaging, precise, and to the point.

3. Market Analysis

The market analysis section of your business plan should offer a thorough understanding of the industry with the target market, competitors, and growth opportunities. You should include the following components in this section.

Target market:

Start this section by describing your target market. Define your ideal customer and explain what types of services they prefer. Creating a buyer persona will help you easily define your target market to your readers.

Market size and growth potential:

Describe your market size and growth potential and whether you will target a niche or a much broader market.

Competitive Analysis:

Market trends:.

Analyze emerging trends in the industry, such as technology disruptions, changes in customer behavior or preferences, etc. Explain how your business will cope with all the trends.

Regulatory Environment:

Here are a few tips for writing the market analysis section of your welding business plan:

- Conduct market research, industry reports, and surveys to gather data.

- Provide specific and detailed information whenever possible.

- Illustrate your points with charts and graphs.

- Write your business plan keeping your target audience in mind.

4. Welding Services

The product and services section should describe the specific services and products that will be offered to customers. To write this section should include the following:

Welding services:

Mention the welding services your business will offer. This list may include services like,

- Metal fabrication

- Welding & repair services

- On-site welding services

- Structural steel & pipe welding

- Custom artistic welding

Describe each service

: Provide a detailed description of each service you provide, including the process involved;

Quality measures

: This section should explain how you maintain quality standards and consistently provide the highest quality service.

Additional Services

In short, this section of your welding plan must be informative, precise, and client-focused. By providing a clear and compelling description of your offerings, you can help potential investors and readers understand the value of your business.

5. Sales And Marketing Strategies

Writing the sales and marketing strategies section means a list of strategies you will use to attract and retain your clients. Here are some key elements to include in your sales & marketing plan:

Unique Selling Proposition (USP):

Define your business’s USPs depending on the market you serve, the equipment you use, and the unique services you provide. Identifying USPs will help you plan your marketing strategies.

Pricing Strategy:

Marketing strategies:, sales strategies:, customer retention:.

Overall, this section of your welding company business plan should focus on customer acquisition and retention.

Have a specific, realistic, and data-driven approach while planning sales and marketing strategies for your welding business, and be prepared to adapt or make strategic changes in your strategies based on feedback and results.

6. Operations Plan

The operations plan section of your business plan should outline the processes and procedures involved in your business operations, such as staffing requirements and operational processes. Here are a few components to add to your operations plan:

Staffing & Training:

Operational process:, equipment & machinery:.

Include the list of equipment and machinery required for welding, such as welding machines, welding tools & accessories, welding consumables & accessories, cutting equipment, etc.

Adding these components to your operations plan will help you lay out your business operations, which will eventually help you manage your business effectively.

7. Management Team

The management team section provides an overview of your welding business’s management team. This section should provide a detailed description of each manager’s experience and qualifications, as well as their responsibilities and roles.

Founders/CEO:

Key managers:.

Introduce your management and key members of your team, and explain their roles and responsibilities.

Organizational structure:

Compensation plan:, advisors/consultants:.

Mentioning advisors or consultants in your business plans adds credibility to your business idea.

This section should describe the key personnel for your welding business, highlighting how you have the perfect team to succeed.

8. Financial Plan

Your financial plan section should provide a summary of your business’s financial projections for the first few years. Here are some key elements to include in your financial plan:

Profit & loss statement:

Cash flow statement:, balance sheet:, break-even point:.

Determine and mention your business’s break-even point—the point at which your business costs and revenue will be equal.

Financing Needs:

Be realistic with your financial projections, and make sure you offer relevant information and evidence to support your estimates.

9. Appendix

The appendix section of your plan should include any additional information supporting your business plan’s main content, such as market research, legal documentation, financial statements, and other relevant information.

- Add a table of contents for the appendix section to help readers easily find specific information or sections.

- In addition to your financial statements, provide additional financial documents like tax returns, a list of assets within the business, credit history, and more. These statements must be the latest and offer financial projections for at least the first three or five years of business operations.

- Provide data derived from market research, including stats about the industry, user demographics, and industry trends.

- Include any legal documents such as permits, licenses, and contracts.

- Include any additional documentation related to your business plan, such as product brochures, marketing materials, operational procedures, etc.

Use clear headings and labels for each section of the appendix so that readers can easily find the necessary information.

Remember, the appendix section of your welding business plan should only include relevant and important information supporting your plan’s main content.

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.

This sample welding business plan will provide an idea for writing a successful welding plan, including all the essential components of your business.

After this, if you still need clarification about writing an investment-ready business plan to impress your audience, download our welding business plan pdf .

Related Posts

Woodworking Business Plan

Painting Business Plan

10 Best Business Plan Software

Important Key Elements of Business Plan

Key Business Problem Statement Examples

Steps for Creating Business Plan

Frequently asked questions, why do you need a welding business plan.

A business plan is an essential tool for anyone looking to start or run a successful welding business. It helps to get clarity in your business, secures funding, and identifies potential challenges while starting and growing your business.

Overall, a well-written plan can help you make informed decisions, which can contribute to the long-term success of your welding company.

How to get funding for your welding business?

There are several ways to get funding for your welding business, but self-funding is one of the most efficient and speedy funding options. Other options for funding are:

- Bank loan – You may apply for a loan in government or private banks.

- Small Business Administration (SBA) loan – SBA loans and schemes are available at affordable interest rates, so check the eligibility criteria before applying for it.

- Crowdfunding – The process of supporting a project or business by getting a lot of people to invest in your business, usually online.

- Angel investors – Getting funds from angel investors is one of the most sought startup options.

Apart from all these options, there are small business grants available, check for the same in your location and you can apply for it.

Where to find business plan writers for your welding business?

There are many business plan writers available, but no one knows your business and ideas better than you, so we recommend you write your welding business plan and outline your vision as you have in your mind.

What is the easiest way to write your welding business plan?

A lot of research is necessary for writing a business plan, but you can write your plan most efficiently with the help of any welding business plan example and edit it as per your need. You can also quickly finish your plan in just a few hours or less with the help of our business plan software .

Can a good welding business plan help me secure funding?

Indeed. A well-crafted welding business plan will help your investors better understand your business domain, market trends, strategies, business financials, and growth potential—helping them make better financial decisions.

So, if you have a profitable and investable business, a comprehensive business plan can certainly help you secure your business funding.

What's the importance of a marketing strategy in a welding business plan?

Marketing strategy is a key component of your welding business plan. Whether it is about achieving certain business goals or helping your investors understand your plan to maximize their return on investment—an impactful marketing strategy is the way to do it!

Here are a few pointers to help you understand the importance of having an impactful marketing strategy:

- It provides your business an edge over your competitors.

- It helps investors better understand your business and growth potential.

- It helps you develop products with the best profit potential.

- It helps you set accurate pricing for your products or services.

About the Author

Upmetrics Team

Upmetrics is the #1 business planning software that helps entrepreneurs and business owners create investment-ready business plans using AI. We regularly share business planning insights on our blog. Check out the Upmetrics blog for such interesting reads. Read more

Plan your business in the shortest time possible

No Risk – Cancel at Any Time – 15 Day Money Back Guarantee

Popular Templates

Create a great Business Plan with great price.

- 400+ Business plan templates & examples

- AI Assistance & step by step guidance

- 4.8 Star rating on Trustpilot

Streamline your business planning process with Upmetrics .

Join In Arccaptain Community | Discuss Here

- Plasma Cutter

- Used Welder and Equipment

- Protective Gears

- Welding Helmet

- Welding Consumables

- Welding Gun and Torchs

- Welding Wires

- Welding Glove

- Welding Tools

- Spring Sale

- Welding Blog

- User Manual

- Track My Order

- Rewards Program

- Arccaptain MIG200

- Arccaptain AC/DC TIG200P

- Arccaptain MIG130

- Arccaptain CUT50

- Arccaptain ARC200

- USER MANUAL

- Join Our Community

We will send you an email to reset your password.

Search our store

10 steps on how to start a welding business.

Jan 25, 2024

Are you a skilled welder looking to turn your passion into a profitable business venture? Starting a welding business can be a challenging yet rewarding experience. With the right tools and knowledge, you can build a successful welding business that provides you with financial stability and the freedom to work on your own terms. In this article, we will provide you with the essential steps to help you start a welding business from scratch.

The process of starting a welding business may seem overwhelming, but with careful planning and execution, you can achieve your goals. From registering your business to acquiring the necessary equipment and finding clients, we will guide you through the entire process. Whether you are a beginner or an experienced welder, this article will provide you with the tools and resources you need to start a thriving welding business. So, let's dive in and explore how to start a welding business.

Understanding the Welding Industry

Starting a welding business requires a good understanding of the welding industry. This section will provide you with an overview of the welding industry, current trends, and future outlook. You will also learn about the relevance and demand for welding services.

Market Research and Target Market

Before starting your welding business, it is important to conduct market research to identify your target market. This will help you determine the types of welding services that are in demand in your area. You can conduct market research by talking to potential customers, analyzing competitors, and researching industry trends.

Your target market may include individuals, businesses, or government agencies. You may also want to consider specializing in a particular niche market, such as automotive welding, construction welding, or custom metal fabrication.

Industry Trends and Demand

The welding industry is constantly evolving, with new technologies and techniques emerging all the time. It is important to stay up-to-date with industry trends and demand to ensure that your welding business remains competitive.

Some current trends in the welding industry include the use of automation and robotics, the growing demand for eco-friendly welding, and the increasing popularity of mobile welding services. To stay ahead of the competition, consider investing in new technologies and training your employees in the latest welding techniques.

Identifying Your Niche

Identifying your niche is crucial to the success of your welding business. By specializing in a particular type of welding, you can differentiate yourself from your competitors and attract customers who need your specific services.

Some examples of niche welding businesses include underwater welding, aerospace welding, and artistic welding. When choosing your niche, consider your skills and experience, as well as the demand for your services in your area.

In conclusion, understanding the welding industry is essential for starting a successful welding business. By conducting market research, staying up-to-date with industry trends, and identifying your niche, you can position your business for long-term success.

Different Kinds of Welding Businesses

To start your own business, you must decide what type of firm you want to manage. There are several options available, each with their own set of advantages and disadvantages. Here are some good business to consider:

- Mobile Welding Business : These businesses travel to customers' locations to provide welding services, often for repairs or on-site construction projects.

- Custom Fabrication Shops : These shops specialize in creating custom metal pieces for various uses, from art to specialized machinery, based on customers' specific designs and needs.

- Industrial Welding Companies : These companies focus on large-scale welding projects, often for manufacturing or construction industries, involving heavy machinery and extensive structural work.

- Underwater Welding Service : This service specializes in w elding tasks performed underwater, often for ship repair or underwater structures, requiring skilled divers with welding expertise.

- Breakdown Welding Service : This type of business focuses on emergency repairs, offering quick welding solutions for broken machinery or structures to minimize downtime.

- Heavy Stainless Steel Fabricating : This business deals with creating large, strong items from stainless steel, often used in industries needing durable and corrosion-resistant products.

- Aluminum Welding : Specializing in welding aluminum materials, this service is sought after for lightweight yet strong structures, common in automotive and aeronautical industries.

- Heavy Haulage Trailer Manufacturing : This business designs and builds large trailers used for transporting heavy loads, requiring expertise in robust welding and structural integrity.

- Steel Construction Fabricating : Focused on constructing steel frameworks for buildings and infrastructure, this business plays a crucial role in the construction industry, offering expertise in large-scale steel welding and fabrication.

Here are 10 steps to follow to start a business with welding:

- Creating a Welding Business Plan

- Legal Considerations

- Setting Up Finances

- Location and Equipment

- Building Your Brand or Business Name

- Operational Management

- Marketing and Customer Acquisition

- Insurance and Risk Management

- Welding Certifications and Training

- Growing Your Business

This basic guide to beginning a welding business has been put together by us. These stages will guarantee that your new company is well-planned, correctly registered, and legally compliant.

1. Creating a Welding Business Plan

To run a business, creating a solid business plan is essential to ensure your success. A business plan will help you outline your operations, financial plan, and marketing strategy. Here are some key factors to consider when creating your welding business plan.

Outline of Operations

Your outline of operations should include a detailed description of your welding services, such as the types of welding you specialize in, the materials you work with, and the equipment you use. You should also outline your workflow, including how you will receive and fulfill orders, manage your inventory, and handle customer service.

Financial Plan

Your financial plan should include startup costs, projected revenue, and expenses. This will help you determine how much funding you will need to start your business and how much revenue you will need to generate to break even and turn a profit. You should also consider factors such as pricing strategies, payment terms, and cash flow management.

Marketing Strategy

Your marketing strategy should outline how you plan to promote your welding business to potential customers. This may include advertising, social media, networking, and referrals. You should also conduct market analysis to identify your target audience and competitors, and develop a unique value proposition that sets your welding business apart from the competition.

By creating a comprehensive business plan, you can set yourself up for success in the competitive world of welding. With a solid plan in place, you can confidently move forward with your business and achieve your goals.

2. Legal Considerations

Starting a welding business requires you to consider various legal aspects to ensure compliance with regulations and protect yourself from legal liabilities. Here are some legal considerations to keep in mind:

Choosing a Legal Entity

Choosing a legal entity is an essential step when starting a welding business. You can choose from different legal entities, such as a sole proprietorship, partnership, LLC, or corporation. Each entity has its own advantages and disadvantages, so it's crucial to choose one that best suits your business needs.

Registering the Business

After choosing a legal entity, you need to register your business with the government. This process involves obtaining a Doing Business As (DBA) name, an Employer Identification Number (EIN), and registering for taxes. You may also need to obtain a business license and permits, depending on your location and the type of welding services you offer.

Licenses and Permits