Running an Aircraft Manufacturing Company – Tips for Success

- Establish a clear vision and a realistic business plan for your aircraft manufacturing company.

- Source quality materials and maintain a good inventory, including efficient storage units for aircraft parts.

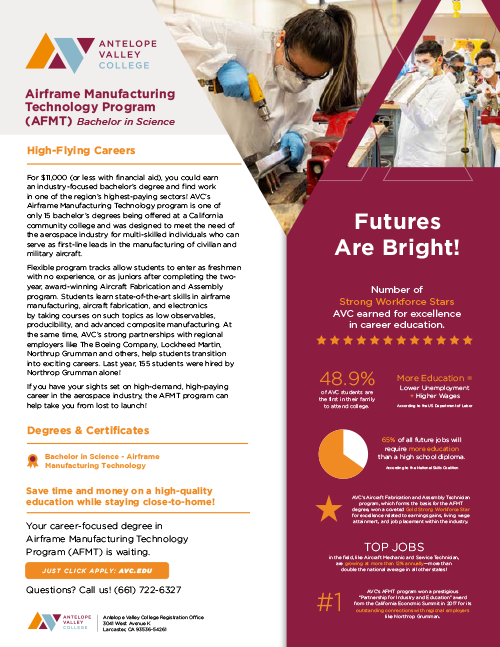

- Attract and retain skilled employees through competitive benefits, training, and career development opportunities.

- Foster strong customer relationships through quick response, quality support, rewards, and keeping them informed.

- Ensure good financial control for better tracking of performance indicators and profitability in your company.

Running an aircraft manufacturing company is no easy feat. From developing the design to managing employees, production, and customer relationships, producers face several challenges. However, you can succeed and thrive in this industry with the right approach and mindset. This blog will share essential tips for running an aircraft manufacturing company successfully.

Develop a Clear Vision and Stick to It

To run a successful aircraft manufacturing company, you must have a clear vision of what you want to achieve and how to get there. You need to set realistic and achievable goals, establish a long-term plan, and ensure everyone in your organization is on the same page.

Ensure your plans and vision are firm and constantly reviewed and refined so everyone knows what is expected of them. Having a vague idea of what you want isn’t enough. Successful businesses start with a clear focus and a thorough and realistic business plan.

Source Quality Materials

When producing aircraft, you need to source quality materials and components. This will ensure the craft is made with precision and safety measures in mind. Do your research into reputable suppliers and make sure you have a good inventory of parts so you can respond quickly to customer orders.

It’s also important to remember that your aircraft’s components aren’t the only quality materials you need to source. Even something small, like the storage units for your aircraft parts, can make all the difference. Invest in good quality aircraft parts storage units so your parts are organized and accessible when you need them. These storage units can also be customized to fit the exact size and needs of your particular aircraft.

Attract and Retain Talented Employees

Employees are at the heart of any successful company. To produce the best aircraft, you need skilled and experienced employees who are passionate about their work. Make sure to put in place a competitive benefits package like healthcare, retirement plans, and bonuses that keep your employee motivated and encourage them to stay with your company for the long term. Offer training and career development opportunities to help keep your employees growing both professionally and personally.

Build Strong Customer Relationships

One of the core features of a successful aircraft manufacturing company is having satisfied customers. They not only bring repeat business but also spread the good word about your products and services, which can bring new customers to you. To ensure you have satisfied customers, build a strong relationship with them. Here are four ways you can achieve this:

Respond to customer queries quickly.

Responding to customer queries quickly will show them that you value their time and opinion, which can help build trust. You can do this by setting up a customer service system that responds to queries quickly and efficiently.

Provide quality support.

Providing excellent customer support is vital for keeping customers satisfied. This includes responding to their issues promptly and helping them resolve any problems they may have with your products or services.

Offer rewards and discounts.

Rewarding loyal customers with discounts or exclusive offers can encourage them to continue doing business with your company. You can also reward customers for referring friends or family members, which can help spread your reputation and reach.

Keep them informed.

Keep customers updated about changes in your products and services, such as new features or updates that they can benefit from. This will make them feel valued as you are keeping them informed about what’s going on in your company.

By building solid relationships with your customers, you can ensure they remain satisfied and come back to you in the future.

Maintain Strong Financial Control

The last tip for succeeding in aircraft manufacturing is maintaining good financial control. Financial control helps you track key performance indicators, minimize waste, and measure profitability.

With good accounting and finance systems, you can identify inefficiencies and invest resources intelligently to achieve your goals. You may consider getting professional help to maintain and prepare your financial statements.

Running a successful aircraft manufacturing company requires a clear vision, sourcing quality materials, attracting and retaining talented employees, building strong customer relationships, and maintaining strong financial control.

These are not easy tasks, but your company can thrive in this competitive industry by committing to these principles. Remember that every step, no matter how small, is a step towards achieving your goal. Stay focused on your vision, remain adaptable, and strive for excellence.

About The Author

Sophie Reed

Start typing and press enter to search.

- Search Search Please fill out this field.

The Airplane Manufacturing Market

Top aircraft manufacturers, the bottom line.

- Fundamental Analysis

- Sectors & Industries

Who Are the Major Airplane Manufacturing Companies?

Adam Hayes, Ph.D., CFA, is a financial writer with 15+ years Wall Street experience as a derivatives trader. Besides his extensive derivative trading expertise, Adam is an expert in economics and behavioral finance. Adam received his master's in economics from The New School for Social Research and his Ph.D. from the University of Wisconsin-Madison in sociology. He is a CFA charterholder as well as holding FINRA Series 7, 55 & 63 licenses. He currently researches and teaches economic sociology and the social studies of finance at the Hebrew University in Jerusalem.

:max_bytes(150000):strip_icc():format(webp)/adam_hayes-5bfc262a46e0fb005118b414.jpg)

Katrina Ávila Munichiello is an experienced editor, writer, fact-checker, and proofreader with more than fourteen years of experience working with print and online publications.

:max_bytes(150000):strip_icc():format(webp)/KatrinaAvilaMunichiellophoto-9d116d50f0874b61887d2d214d440889.jpg)

Although the airline industry is highly competitive, the competition among aircraft suppliers is relatively limited. Lesser-known makers of large passenger airplanes are attempting to build a more significant presence on the world's stage. Still, in the large commercial aircraft market, there are just two major players: the U.S.-based Boeing ( BA ) and the Airbus Group ( EADSY ), formerly known as the European Aeronautic Defense and Space Company (EADS).

Key Takeaways

- The global airplane manufacturing market is valued at over $400 billion.

- The world's only major large passenger aircraft manufacturers are Boeing and Airbus.

- Boeing's and Airbus's established jet brands are the 7-series and A-series, respectively.

- Up-and-coming large passenger airplane makers include Comac in China, Mitsubishi in Japan, and UAC in Russia.

- Based on deliveries, Airbus takes the top spot as the largest airplane manufacturer in the world.

Airbus is the world's top commercial airplane manufacturer based on airplanes delivered. Boeing is in second place, as its deliveries stalled because of the grounding of certain aircraft, the COVID-19 pandemic, and issues for its 737-MAX aircraft.

The airplane manufacturing market is part of the overall airline industry. The global market's estimated value was more than $400 billion in 2023, and is expected to grow to more than half-a-trillion dollars by 2029. Companies in this market are involved in the manufacturing of airplanes and their components, including engines and propulsion systems.

Large passenger airplane manufacturers

Boeing and Airbus are the world's only major large passenger aircraft manufacturers. The two companies share almost exclusive control of the worldwide airplane supply business for large commercial jets. Their established brands are Boeing's 7-series and Airbus's A-series of jets. These aircraft include narrow-body aircraft, wide-body aircraft, and jumbo jets.

Regional and other international airplane manufacturers

Bombardier, based in Canada, and Embraer, a Brazilian aircraft manufacturer, are leaders in the regional and business airplanes market. They both focus on smaller-sized jets.

On a global scale, competition with Boeing and Airbus is brutal. However, newer airline suppliers Comac in China, Mitsubishi in Japan, and UAC in Russia are working on a series of new wide-body jets in a joint venture . They hope to eventually become a legitimate competitor that can take on the dominance of Boeing and Airbus in the large-jet space.

Military airplane manufacturers

Boeing and Airbus have a significant market share in the supply of military aircraft, particularly in the U.S. Their competition in this market includes Lockheed Martin. Just under half of Boeing's revenues came from U.S. government contracts in 2022. Only about 20% of Airbus' revenues came from defense contracts in 2022.

Suppliers to airplane manufacturers

Aerospace suppliers are critical to the aircraft manufacturing ecosystem. They provide essential components, systems, and materials required to build an aircraft. This includes avionics, propulsion systems, landing gear, cabin interiors, and composite materials. These suppliers range from large companies that produce major systems to smaller specialized firms. Aircraft manufacturers rely on these suppliers for the initial construction of aircraft and ongoing maintenance and replacement parts.

Raytheon Technologies Corporation ( RTX ) and General Electric ( GE ) are two major companies that manufacture airplane engines and other parts for industry operators. Rolls-Royce ( RYCEY ), Pratt & Whitney, and Honeywell ( HON ) also produce airplane jet and propeller engines.

Here are some of the largest aircraft manufacturers in the world. All data as of Q1 2024.

Boeing (BA)

- Headquarters : Chicago, Illinois, USA

- Founded : 1916

- Market Cap : $130 billion

- Employees : 156,000

- Products : Known for manufacturing a wide range of commercial jetliners, Boeing's product line includes the 737, 747, 767, 777, and 787 families of airplanes. The company also offers military aircraft, satellites, and other aerospace products and services.

Once the darling of the aircraft business, Boeing has faced some critical challenges recently, most notably issues related to the safety of its aircraft. Incidents involving the 737-MAX's in-flight controls and aircraft doors detaching midflight have raised serious concerns. These issues have not only affected Boeing's reputation and financial stability but also have wider implications for airline safety standards and consumer confidence in the industry.

Airbus (EADSY)

- Headquarters : Leiden, Netherlands

- Founded : 1970

- Market Cap : $128.6 billion

- Company Size : 134,000

- Products : Airbus is known for its commercial aircraft, including the A220, A320, A330, A350, and A380 families. The company also produces military planes and helicopters and provides aerospace-related services.

Lockheed Martin (LMT)

- Headquarters : Bethesda, Maryland

- Founded : 1995 (from the merger of Lockheed Corporation and Martin Marietta)

- Market Cap : $113.6 billion

- Employees : 116,000

- Products : While focused on defense and military aircraft, such as the F-16 and F-35 Lightning II, Lockheed Martin also engages in aeronautics, missiles, fire control, and space systems.

Embraer (ERJ)

- Headquarters : São Paulo, Brazil

- Founded : 1969

- Market Cap : $3.2 billion

- Employees : 18,000

- Products : Embraer is known for its E-Jet and E-Jet E2 series of regional jets, popular among airlines for short to medium-haul flights.

Boeing comes in second as the largest airplane manufacturer in the world because of manufacturing problems that led the Federal Aviation Administration (FAA) to halt deliveries of its 787 model.

Bombardier (BDRBF)

- Headquarters : Montreal, Quebec, Canada

- Founded : 1942

- Market Cap : $3.7 billion

- Employees : 15,000

- Products : The company's aerospace division is known for its business jets, including the Challenger and Global series.

How Are New Aircraft Certified to Fly?

Aircraft certification is a rigorous and detailed process conducted by aviation authorities such as the FAA in the U.S. or the European Union Aviation Safety Agency (EASA) in Europe. This process involves extensive testing and evaluation of the aircraft's design, construction, and performance to ensure it meets strict safety standards. It includes analysis of the airframe, engines, systems, and flight performance, with assessments of the aircraft's handling under various conditions.

How do market dynamics between Boeing and Airbus influence the airplane manufacturing industry?

The duopoly of Boeing and Airbus significantly influences market dynamics in the airplane manufacturing industry. Their competition is legendary, driven by their high-stakes duopoly, the need to stay ahead in avionics and other changing technology, and the geopolitics around Boeing being a major American company and Airbus being a European consortium. As manufacturing for other goods had for decades been moving out of Europe and the U.S., these two companies were also emblems of what the U.S. and Europe could still produce.

Court battles, World Trade Organization complaints, and negotiations at the highest political levels for aircraft contracts mean more is at stake than simply any new plane put out by one requires an answer from the other. Together, this duopoly's decisions on production rates, aircraft models, and what technology they will use set trends for the entire industry, affecting everything from airline fleet choices to what kind of technology pilots and regular consumers will find once on board.

How Did the COVID-19 Pandemic Impact Aircraft Manufacturers?

The COVID-19 pandemic significantly impacted the aircraft manufacturing industry. There was a drastic cut in demand for new aircraft because of the sudden decline in air travel. This led to production slowdowns, delays in aircraft deliveries, and financial challenges for manufacturers. However, the industry has been adapting by focusing on more flexible manufacturing processes, increasing cargo aircraft production because of the rise in ecommerce and accelerating digital transformation to improve efficiency.

The airplane manufacturing market, valued at over $400 billion, is a significant part of the global airline industry, which is expected to grow considerably over the next decade. Dominated by Boeing and Airbus, the only major manufacturers of large commercial jets, this market is characterized by their iconic 7x7-series and A3xx-series jets. Suppliers, including GE, Raytheon Technologies, and Rolls-Royce, are pivotal in providing essential components like engines and avionics. While facing lingering challenges from the COVID-19 pandemic leading to reduced demand and production, the industry is adapting through flexible manufacturing and other changes. Boeing, in particular, has encountered significant mechanical challenges with its 737-MAX and 787 models, affecting its position in the global market.

Precedence Research. " Aircraft Manufacturing Market Size Global Report, 2023-2032. "

The Boeing Company. " 2022 Annual Report. "

Airbus. " Financial Results and Annual Report ."

Raytheon Technologies. " United Technologies and Ratheon Complete Merger of Equals Transaction. "

Companies Market Cap. " Top Aircraft Companies - Employees ."

Economic Times . " Boeing’s Legacy Vanished Into Thin Air and Saving It Will Take Years ."

Airbus. "Who We Are"

Lockheed Martin. "Who We Are"

Embraer.com. "About Us"

Federal Aviation Administration. " Airworthiness Certification ."

Ayoung Woo, et al. " An Analysis of the Competitive Actions of Boeing and Airbus in the Aerospace Industry Based on the Competitive Dynamics Model ." Journal of Open Innovation: Technology, Market, and Complexity . 7,.3 (2021).

McKinsey & Co. " COVID-19's Impact on the Global Aviation Sector ."

- Terms of Service

- Editorial Policy

- Privacy Policy

- Your Privacy Choices

How to Start an Aerospace Company

By: Author Tony Martins Ajaero

Home » Business ideas » Aviation Industry

An aerospace company is a business that designs, develops, and manufactures products related to the aerospace industry, including aircraft, spacecraft, missiles, rockets, and other types of vehicles that operate in or beyond Earth’s atmosphere.

Aerospace companies may also provide maintenance, repair, and overhaul services for these products, as well as engineering and technical support, research and development, and other related services.

The aerospace industry is a very large industry and available statistics show that the value of the global aerospace market reached $298 billion in 2020, with North America accounting for almost half of the total.

It is expected to grow at a rate of 7.7 percent to $430.7 billion in 2025, and a further 5.9 percent annually until 2030 to a total of $573.6 billion.

Steps on How to Start An aerospace Company

Conduct market research.

Conducting market research for an aerospace company involves gathering and analyzing information about the aerospace industry and the specific markets in which the company operates. First, you need to determine what the company wants to achieve from the market research.

For example, the objective could be to identify new markets for the company’s products or to understand the competitive landscape. Next, you are expected to determine the group of people or companies that the research will focus on. This could include customers, suppliers, competitors, and regulators. Decide on the best method to gather information.

This could include surveys, interviews, focus groups, or secondary research such as industry reports and government data. Design the research questions to help answer the research objectives. Questions should be clear and concise and avoid bias.

Lastly, collect data using the chosen research method. Ensure that the data is accurate and reliable and that the sample size is appropriate. Review the data and identify patterns and trends. Look for insights that can help the company achieve its research objectives.

a. Who is the Target Market for Aerospace Companies?

The target market for an aerospace company depends on the specific products and services that the company offers. Generally, the primary customers for aerospace companies are government organizations, such as space agencies and defense departments, as they are the largest purchasers of aerospace products and services.

For commercial aerospace companies that manufacture and operate passenger aircraft, their target market is primarily airlines, as well as leasing companies and other organizations that provide aircraft to airlines. These companies may also target individual customers through marketing campaigns to promote travel on their airline customers’ flights.

For space exploration and tourism companies, their target market includes individuals who are interested in space tourism, as well as governments or private companies who want to launch satellites or conduct research in space.

b. Is an Aerospace Company a Profitable Business?

Yes, the aerospace company is considered a profitable business. The global aerospace market reached $298 billion in 2020, with North America accounting for almost half of the total. It is expected to grow at a rate of 7.7 percent to $430.7 billion in 2025, and a further 5.9 percent annually until 2030 to a total of $573.6 billion.

c. Are There Existing Niches in the Industry?

Yes, there are existing niches when it comes to aerospace companies. Here are some of them.

- Commercial aerospace companies

- Space exploration and tourism companies.

d. Who are the Major Competitors?

- Lockheed Martin

- Northrop Grumman

- Raytheon Technologies

- General Electric Aviation

- General Dynamics

- Pratt & Whitney

- Honeywell Aerospace

- Collins Aerospace

- Textron Aviation

- Gulfstream Aerospace

- Bombardier Aerospace

- United Launch Alliance

- Blue Origin

- Virgin Galactic

- Sierra Nevada Corporation

- Aerojet Rocketdyne

- Ball Aerospace.

e. Are There County or State Regulations or Zoning Laws for Aerospace Companies?

Yes, there are county and state regulations, as well as zoning laws, that apply to aerospace companies in the United States. These regulations and laws vary depending on the specific location and type of activities that the aerospace company engages in.

For example, if an aerospace company wants to build a new facility, it may need to comply with zoning laws that regulate land use and building requirements. This may involve obtaining permits, complying with setback requirements, and meeting environmental and safety regulations.

In addition, aerospace companies that engage in defense-related activities are subject to export control regulations that limit the export of sensitive technology and products to certain countries or individuals. Finally, aerospace companies must comply with various federal regulations that govern the industry, such as those related to aviation safety, aircraft certification, and space launch licensing.

f. Is There a Franchise for an Aerospace Company?

No, there are no franchise opportunities for aerospace companies.

g. What Do You Need to Start an Aerospace Company?

- A Feasibility Report

- Business and Marketing Plans

- Business Licenses and Permits

- Operations or Production Facility

- EIN (Employer Identification Number)/Federal Tax ID Number.

- A Corporate Bank Account

- Equipment, Machines, and Supplies

- Startup and Working Capital

Choose a Memorable Business Name

When looking to start a business, before you can begin to file the necessary documents with the constituted authorities or start your website, it is necessary that you come up with a name that you will be recognized with. It is essential that the name you come up with can easily be pronounced, is unique and easily memorable.

Some of the catchy business name ideas suitable for an aerospace business are;

Creative Aerospace Business Name ideas

- Silver Stream® Aerospace Company, Inc.

- Copper Hills® Aerospace Company, LLC

- Eddie Smith® Aerospace Company, Inc.

- Gold Flash® Aerospace Company, Inc.

- Blue Sky® Aerospace Company, Inc.

- Quartz Ultimate® Aerospace Company, Inc.

- Jeff Jefferson® Aerospace Company, LLC

- Sky Resources® Aerospace Company, Inc.

- Julius Czar® Aerospace Company, LLC

- Fly Wave™ Aerospace Company, Inc.

- Beyond Cloud® Aerospace Company, Inc.

- Richard Williams® Aerospace Company, Inc.

- Harry Johnson™ Aerospace Company, Inc.

- Jonah Serville® Aerospace Company, Inc.

- Bright Anderson® Aerospace Company, LLC

- Silver Meta® Aerospace Company, Inc.

- Golden Wings® Aerospace Company, Inc.

- Copper Bird™ Aerospace Company, Inc.

- The Unicorn® Aerospace Company, Inc.

- Eagles Wing® Aerospace Company, Inc.

Register Your Business

A. what type of business structure is best for an aerospace company.

The ideal business structure for an aerospace company is determined by a variety of factors, including the size of the company, the number of owners, the level of personal liability the owners are ready to accept, and the tax consequences of the various business structures.

However, we normally recommend a limited liability company structure. This is so because an LLC is a hybrid corporate form that provides the flexibility of a partnership while also providing its owners with limited liability protection.

An LLC can have one or more owners, and the owners are not personally accountable for the debts or liabilities of the business. This business form is frequently used for small to medium-sized organizations.

b. Steps to Form an LLC

- Choose a Name for Your LLC.

- File Articles of Organization.

- Choose a registered agent.

- Decide on member vs. manager management.

- Create an LLC operating agreement.

- Comply with other tax and regulatory requirements.

- File annual reports.

c. What Type of License is Needed to Open an Aerospace Company?

- General Business License

- Federal Aviation Administration (FAA) Licenses

- Export Licenses

- Occupational Licenses

- Environmental permits

- Building permit

- Zoning Permit

- Signage Permit

d. What Type of Certification is Needed to Open an Aerospace Company?

- Federal Aviation Administration (FAA) Certification

- International Organization for Standardization (ISO) Certifications

- National Aerospace and Defense Contractors Accreditation Program (NADCAP) Certification

- International Traffic in Arms Regulations (ITAR) Compliance

- Quality System Standard AS9100 Certification

- Space Launch Approval.

e. What Documents are Needed to Open an Aerospace Company?

- Business and liability insurance

- Federal Tax Payer’s ID

- Certificate of Incorporation

- Professional Certifications

- Business License

- Business Plan

- Operating Agreement for LLCs

- Insurance Policy

- Zonal Permit

f. Do You Need a Trademark, Copyright, or Patent?

Yes, an aerospace company may need to obtain a trademark, copyright, or patent depending on the specific products, services, or technologies involved. An aerospace company may want to obtain a trademark for its company name, logo, or specific product names to prevent others from using similar names or logos in a way that could cause confusion among consumers.

An aerospace company may want to obtain a copyright for software, technical drawings, or marketing materials to prevent others from copying or using these materials without permission.

A patent protects an invention or discovery, such as a new aircraft engine or satellite technology. An aerospace company may want to obtain a patent for a new technology or product to prevent others from making, using, or selling the same invention without permission.

Cost Analysis and Budgeting

A. how much does it cost to start an aerospace company.

The cost to start an aerospace company can vary greatly depending on a number of factors, such as the type of aerospace operation, the location, the size of the company, and the equipment and resources required. However, a rough estimate could range from $20 million to over $100 million, depending on the size and scope of the business.

b. What are the Costs Involved in Starting an Aerospace Company

- Legal and administrative costs (the cost of obtaining business licenses and permits, registering the business, and consulting with attorneys and accountants): $172,500

- Equipment and supplies: $15 million

- Staffing costs: $500,000

- Rent/lease: $1 million

- Marketing and advertising costs: $20,000

- Insurance costs: $450,000

- Miscellaneous Expenses: $75,000.

c. What Factors Determine the Cost of Opening an Aerospace Company?

- The type of aerospace company

- The size of the aerospace company

- The choice of location

- The required licenses and permits

- The cost of hiring and paying a business consultant and attorney

- The cost of branding, promotion, and marketing of the aerospace company

- The cost of equipment

- The cost of the insurance policy covers

- The cost OF registering the business

- Source of your supplies and ongoing expenses

- Cost of recruiting and training your staff

- The cost of the purchase and customizing of uniforms

- The cost for the grand opening of the aerospace company.

d. Do You Need to Build a Facility? If YES, How Much Will It Cost?

Whether an aerospace company needs to build a facility depends on the specific activities involved. For example, an aerospace company involved in aircraft manufacturing, testing, or repair will likely need a facility with specialized equipment and infrastructure to carry out these activities.

On the other hand, an aerospace company involved in software development or consulting may not require a dedicated facility and can operate remotely or in shared office space.

According to a report by the Aerospace Industries Association, the average cost of constructing a new aerospace manufacturing facility in the United States ranges from $200 to $400 per square foot. This means that a facility of 50,000 square feet could cost anywhere from $10 million to $20 million to build.

e. What are the Ongoing Expenses of an Aerospace Company?

- Materials and Supplies

- Equipment and Machinery

- Rent or Mortgage Payments

- Marketing and Advertising

- Research and Development

- Regulatory Compliance (licensing, inspections, and certifications).

f. What is the Average Salary of your Staff?

- Chief Executive Officer (President) – $120,000 per year

- Operations Manager – $80,000 per year

- Aerospace Engineer – $75,000 per year

- Production Manager – $75,000 per year

- Maintenance Manager – $70,000 per year

- Human Resources Manager – $60,000 per year

- Accountant/Financial Manager – $60,000 per year

- Quality Control Inspectors – $55,000 per year

- Safety Officer – $50,000 per year

- Customer Service Executive – $48,000 per year

g. How Do You Get Funding to Start an Aerospace Company?

- Raising money from personal savings and sale of personal stocks and properties

- Raising money from investors and business partners

- Sell shares to interested investors

- Applying for a loan from your bank/banks

- Pitching your business idea and applying for business grants and seed funding from the government, donor organizations, and angel investors

- Source for soft loans from your family members and friends.

Write a Business Plan

A. executive summary.

Copper Bird™ Aerospace Company, Inc. based in Detroit, Michigan is a leading aerospace company that designs, manufactures, and services advanced aerospace systems and components for commercial and military customers around the world.

With over 25 years of experience in the industry, we have built a reputation for delivering innovative solutions that meet the highest standards of quality, reliability, and safety.

At Copper Bird™ Aerospace Company, Inc., we are committed to staying at the forefront of the industry by investing in research and development, and by maintaining a highly skilled and experienced workforce. We also prioritize sustainability and environmental responsibility, and we are dedicated to reducing our carbon footprint and promoting sustainable practices across our operations.

Our team is comprised of highly skilled engineers, technicians, and other professionals who are dedicated to delivering the highest quality products and services to our customers. We have a strong culture of innovation and collaboration, and we are committed to fostering a workplace that is inclusive and supportive of diversity.

b. Products and Service

Our products and services include aircraft engines, avionics systems, satellite components, and other advanced aerospace technologies. We have a proven track record of success, with a diverse portfolio of projects that have been delivered on time and within budget.

c. Mission Statement

Our mission at Copper Bird™ Aerospace Company, Inc. is to design, manufacture, and service advanced aerospace systems and components that enable our customers to explore new frontiers and achieve their goals with safety, reliability, and efficiency.

We are committed to excellence in all aspects of our operations, and we prioritize sustainability and environmental responsibility in everything we do.

Vision Statement

Our vision at Copper Bird™ Aerospace Company, Inc. is to be the leading aerospace company in the world, known for our innovation, quality, and commitment to sustainability. We strive to push the boundaries of what is possible in aerospace technology and to deliver value to our customers, employees, and stakeholders.

d. Goals and Objectives

The goals and objectives of an aerospace company are to design, develop, and manufacture products related to the aerospace industry, including aircraft, spacecraft, missiles, rockets, and other types of vehicles that operate in or beyond Earth’s atmosphere.

They also provide maintenance, repair, and overhaul services for these products, as well as engineering and technical support, research and development, and other related services.

e. Organizational Structure

- Chief Executive Officer (President)

- Operations Manager

- Aerospace Engineer

- Production Manager

- Maintenance Manager

- Human Resources Manager

- Accountant/Financial Manager

- Quality Control Inspectors

- Safety Officer

- Customer Service Executive.

Marketing Plan

A. swot analysis.

- Strong reputation for innovation and quality in the aerospace industry

- A diverse portfolio of products and services, including aircraft engines, avionics systems, and satellite components

- Highly skilled and experienced workforce

- Commitment to sustainability and environmental responsibility

- Strong relationships with major commercial and military customers.

- Dependence on a small number of major customers for a significant portion of revenue

- High costs associated with research and development and compliance with industry regulations

- Vulnerability to changes in economic and political conditions that affect the aerospace industry

- Potential for disruptions to supply chains and production processes.

Opportunities

- Growing demand for advanced aerospace technologies, particularly in emerging markets

- Potential for partnerships and collaborations with other aerospace companies to share expertise and resources

- Expansion into new product areas and markets, such as electric aircraft and space tourism

- The increasing importance of environmental sustainability in the aerospace industry creates opportunities for innovation and differentiation.

- Intense competition from other established aerospace companies and new entrants to the market

- Uncertainty and volatility in global political and economic conditions, affecting demand for aerospace products and services

- Increasing regulatory requirements and compliance costs

- Risks associated with technological advancements, including cybersecurity threats and safety concerns.

b. How Do Aerospace Companies Make Money?

Aerospace companies make money by designing, manufacturing, and servicing advanced aerospace systems and components for commercial and military customers. This includes aircraft engines, avionics systems, satellite components, and other advanced aerospace technologies.

c. Payment Options

- Credit and debit cards

- Apple Pay and Google Wallet

- Gift cards and store credit

- Installment payments

- Cash on delivery.

d. Sales & Advertising Strategies

- Establishing a strong brand

- Developing comprehensive website services, case studies, testimonials, and contact information for potential customers.

- Utilizing social media platforms like LinkedIn and Twitter to connect with potential customers, share updates on new products and services, and engage with industry influencers.

- Attending trade shows and industry events

- Creating whitepapers, blog posts, and other content that positions the company as a thought leader in the industry

- Offering free trials or demos

- Advertising campaigns on search engines, social media platforms, and other channels with the target to reach specific audiences, such as military or commercial customers, based on their interests and behaviors.

Financial Projection

A. how much should you charge for your product/service.

The pricing of products and services for aerospace companies can vary greatly depending on the specific product or service being offered, as well as the target market and competition. Some aerospace products, such as commercial aircraft, can cost hundreds of millions of dollars, while others, such as avionics systems, can cost tens of thousands of dollars.

b. How Much Profit Do Aerospace Company Owners Make a Year?

According to data from IBISWorld, the average profit margin for aerospace products and parts manufacturing in the United States is approximately 9.7 percent, although this can vary widely depending on the specific company and market conditions.

c. What Factors Determine the Amount of Profit to Be Made?

- The capacity of the aerospace company

- The type of products and service offerings

- The location of the aerospace company

- The management style of the aerospace company

- The business approach of the aerospace company

- The advertising and marketing strategies adopted by the aerospace company.

d. What is the Profit Margin of an Aerospace Company?

According to data from IBISWorld, the average profit margin for aerospace products and parts manufacturing in the United States is approximately 9.7 percent. However, this can vary widely depending on the specific product or service being offered.

e. What is the Sales Forecast?

- First Fiscal Year (FY1): $14 million

- Second Fiscal Year (FY2): $28 million

- Third Fiscal Year (FY3): $50 million

Set Up your Shop/Office

A. how do you choose a perfect location for an aerospace company.

- The demography of the location

- The demand for the products and services of aerospace companies in the location

- Accessibility of the location

- The number of aerospace companies in the location

- The local laws and regulations in the community/state

- Availability of airport, traffic, parking, and security et al

b. What State and City is Best to Open an Aerospace Company?

- Seattle, Washington

- Los Angeles, California

- Denver, Colorado

- Huntsville, Alabama

- Wichita, Kansas

- Dallas-Fort Worth, Texas

- Washington, D.C.

- Orlando, Florida

- Phoenix, Arizona

- San Diego, California.

c. What Equipment is Needed to Operate an Aerospace Company?

- Manufacturing equipment such as lathes, milling machines, and drills et al

- Testing equipment such as stress tests, environmental tests, and vibration tests.

- Design and modeling software (Computer-aided design (CAD) software)

- Assembly equipment such as torque wrenches, precision screwdrivers, and pneumatic tools.

- Maintenance and repair of equipment such as hydraulic test stands, engine test cells, and avionics test benches.

- Safety equipment such as personal protective gear, fire suppression systems, and emergency response equipment.

Hire Employees

You are required to create a robust budget for hiring employees for your aerospace company because an aerospace company is not one of those businesses that can be operated by an individual. As a matter of fact, operating an aerospace company requires some key staff members that are trained and certified to work in the aerospace industry.

Launch the Business Proper

Launching a new business is key to how successfully the business can gain traction in the market space. So, you must make sure you organize a launch party that will attract key stakeholders in the industry.

a. What Makes an Aerospace Company Successful?

- Choose a good location to launch the business

- Make sure your products and services are top-notch

- Be deliberate with your marketing sales approach

- Encourage the use of word of mouth to promote your aerospace company

- Leverage all available online and offline platforms to promote your aerospace company

b. What Happens During a Typical Day at an Aerospace Company?

The activities that occur during a typical day at an aerospace company can vary depending on the specific type of products or services offered by the company. However, here are some common activities that may occur:

- Research and development programs to improve existing products, develop new technologies, and explore new applications for aerospace products.

- Manufacturing

- Quality Control including inspections, testing, and documentation.

- Sales and Marketing

- Customer Support including technical support, maintenance, and repair services.

- Collaboration

- Regulatory Compliance.

c. What Skills and Experience Do You Need to Build an Aerospace Company?

- Engineering and Technical Expertise

- Excellent quality control skills

- Excellent sales and customer services skills

- Interpersonal skill

- Attention to details

- Business management skills

- Bargaining and bidding skill

- Work experience in the aerospace industry

- Experience in managing people.

Related Posts:

- How to Start a Private Jet Charter Company

- 50 Best Aviation Business ideas You Can Start Today

- How to Start a Drone Flight School – Sample Business Plan Template

- Airport Management Business Plan [Sample Template]

- How to Start a Flight School Business

Start an Aircraft Manufacturing Business

- 37 comments

- 2 expert advice

- 26,268 views

Far from the common scenario in the past, there are already lots of people who embrace aircraft services, especially if they want to go from one place to another.

- Google Share

This means that people who want to open different kinds of venture can already start an aircraft manufacturing business.

Since aircraft manufacturing might seem to be a complex venture, it is important that you know some information about the matter first. If you are looking for information on how to start aircraft manufacturing business, this article will provide you the things you need to know.

Business Research

Since this might be new to you, it is important that you keep yourself informed of what the business is. This means that you should conduct research in order to orient yourself regarding what it is all about. Basically, you can search for some sites in the internet related to the matter but it is always better if you have substantial period of working experience from the same field. These sites can provide you valuable information to understand the nature of the business deeper. Furthermore, you can also ask other business owners running the same venture in order to know valuable facts about this type of business.

Create Business Plan

First and foremost, people who want to start aircraft manufacturing business should begin actualizing their dream venture by simply creating business plan. The business plan serves as the Bible of your business. This means that it provides guidance on the entire path of your aircraft manufacturing business. Keep in mind that there are important components you should focus on in creating your business plan. Examples of these are:

- General Business Overview

- Goals and Objectives

- Description of Products Offered

- Analysis and Study of the Target Market

- Marketing Strategies to be Used

Legalizing the Business

After the development of strong and concise business plan, the next thing you need to do is to legalize your business. There are some requirements you need to secure in order to legalize your business. All you just need to do is to go to the concerned business licensing agencies and departments in your place to know more about the matter. Of course, the most basic requirement in legalizing your business is applying for a business permit. This might take some time and require you some money. However, this will be all worth it in the end.

Facilities, Location and Staff

To start an aircraft manufacturing business, it is important to consider facilities, location and staff. In terms of facilities, there are machineries you need to use in the future to make this business possible. When it comes to location, choose the best place where you can establish your business. The place should have enough size and is accessible on your part. In addition to that, look for staff that has technical skills regarding aircraft manufacturing. See to it that your staff is also hard working, dedicated to their work and is willing to help you grow your business.

37 Comments

- Ramkumar patne said on January 9, 2013 Hello i'm Ramkumar. i was a students of aeronautical engineering in delhi (INDIA). i have passed three license in AME field. i want to start aircraft manufacturing business in MADHYA PRADESH (INDIA). Plz guide me and tell me about requirement

- Sajjad said on August 21, 2013 @Ramkumar patne, I assume you've just completed your studies so I doubt that you would have much cash with you at this stage of life. Starting a simple aircraft manufacturing business would need an immediate injection of at least $500m.

- Isaac said on February 21, 2014 When you are talking of a simple aircraft manufacturing business and that you need $500 millions to open it, how simple is the business your talking about?

- James said on July 1, 2014 I have a new jet design that will need venture capital not to exceed $20M. Are there other focus areas you would suggest for this type of plan, other than what you have listed?

- Bereket said on July 17, 2014 Are u serious $500m to start up an aircraft manufacturing business. Is worth it??

- pintu sharma said on August 5, 2014 I want to start a two sitter air craft company . Now I am running heavy mechanical job company myself.

- m.sandeep said on August 18, 2014 hi my name is sandeep and i am in aero 2 year. i have only 10 lakhs of money so i want to start air craft manufacturing company in my state and i will provide more jobs to my people so .if any bank or government providing any loan plz tell me about that sir

- yathish kumar said on September 4, 2014 any one can let me know the procedure to start up a new aircraft manufacturing industry.

- Arya Dharmpal Chandresh said on September 15, 2014 I want to manufacturing of Aircraft products in jaipur please suggest me.

- Nimod K.A. said on October 28, 2014 I have a dream of starting an aircraft manufacturing company which will manufacture passenger aircrafts. I have no money with me, but if there are people ready to invest, I am sure I can quit my job and work on this mission. Currently 10 countries have aircraft manufacturing companies which manufacture passenger aircraft and sadly India is not among them. Also linked with 'Make in India' move, I invite people who can support me in this...

- varun jayavelu said on February 27, 2015 @nimod i am interested in your idea of manufacturing passenger aircraft but initially manufacturing paramotors and trikes would be cheaper.

- Alex martinez said on April 8, 2015 Wichita,Kansas USA. I am looking for information in starting up a small assembly shop in the aircraft industry. I know someone who worked at Censa for 20 years, currently is assembling a part for Censa. They have tried to outsource his job to Mexico but they failed. He and I are looking to start up a small Shop and have the correct certification to assembly the part. I know we will need an as 9100 certification that will be for the mechanic but what certification will the inspector need?

- Jose Bay Grajeda said on July 1, 2015 I'm thinking in starting an aerial company ... but how do you start out? coming out of college keeps you pretty broke, so how do i start a business when i have no money to buy the equipment and staff? Please Help!!!

- Boeing international said on July 13, 2015 Love to see that many people wants to open there know aircraft company. Today there are lots of company to boost your company name you should come up with new idea like small jet plane, or solar plane or light weight plane. You should have at least $10 million to start and buy equipments for your dream plane.

- gaurav said on February 1, 2016 Friends i have also same dream as u all have but their is problem of investor with all of us so we can achieve our dream if we work together [email protected] .....guys i know we have fire in our hearts and if we work together we will definitely.....find a way to start this....plz all who r interested msg me on my email id or my watsap no. 9917429225

- Ankur Kamboj said on March 6, 2016 Hi @gaurav , I too have same intentions with lot of energy and interest . Please check your mail. I will encourage other interested persons to share or contact as well.

- vishal said on April 3, 2016 9462588411

- vishal said on April 3, 2016 i want to open myths own aircraft and helecopter company... so u guide me cantact me.. 9462588411

- jaipal kethavath said on April 4, 2016 i have an ultralight aircraft design that i prepaid. so i have also same intention to start a/c man comp.

- Vinod Malshikare said on May 4, 2016 Dear friends, I am vinod malshikare from India. I want to strting new and modern models of aircraft which will be making at least cost and gives best performance. so I will start when a person who guide me perfectly. If any one can help me then please contact mi [email protected] please leave message.

+2348065134393 || [email protected] || Aircraft Manufacturing Expert

- TANAKA MAKUNI said on September 18, 2016 @Jaipal @vishal and EVERYONE .You seem to be anxious and enthusiastic in venturing into this business like everyone else here, so I propose working together. Contact me on whatsapp and maybe we can share ideas, help each other make this a reality. +263773999952

- ranganathan said on November 14, 2016 alright I THINK first we need to focus on the model of the aircraft company and find its estimation and then start all around. then how do we get the raw materials and the scope of the industry in our country. where do i get the information regarding about all that? where do i get the money from? how do i arrange the such huge fund? are there banks to support this? what steps to take in finding it? then where do i find the buyers of my products? are there good HR who can do pretty well in our field in our country? how to get the guidance from the business leaders? how do i startup? plz do contact me ph:9741168215

- DEEPAK KUMAR UPADHYAY said on November 28, 2016 I want to start my own manufacturing plant for aircraft .. kindly suggest me friends, and team from entire world who are interested in same kindly contact me .. email id: [email protected], contact number: +91-7839272383

- Deepak said on December 1, 2016 I want to start my own manufacturing plant for aircraft .. kindly suggest me friends, and team from entire world who are interested in same kindly contact me .. email id: [email protected] contact number: +91-9781940114

[email protected] || Aircraft Industry Adviser

- Ibra Rilz Kasasa. said on January 8, 2017 Hi, am Ibra Rilz in Uganda. Am also interested in aircraft manufacturing. I don't have any money with me now, am in high school. But am sure i have some skills especially the engine, wings and even fuel or gas production. Those who want to start up any aeroplane making business can contact me, i assure that am dedicated and determined and will work to the success of the business.

- premkumar said on March 18, 2017 I am premkumar ame student atjawaharlal aviation institute pala skkad kerala i also have the same dream of starting a microlight aircraft company in kerala but i dont have money or investors for my dream share your valuable ideas to my mail premkumar [email protected]

- ojaskar said on April 13, 2017 i am a indian i also have a dream to start air craft company

- Arush Khjuriya said on January 14, 2018 We Can Make a Whatsapp Group and discuss ideas +91 9911964706

- Rukundo Enock said on January 27, 2018 I am a 20 year old Ugandan on ky way to starting an aircraft manufacturing business

- Vinod said on June 28, 2019 All start-up members plz comments on whats app no. I am starting a group

- oyibe matthew said on September 28, 2019 my name oyibe Matthew. i am a nigerian please I want to start an aircraft manufacturing company. But I don't know how to start. I have some ideas for the name, the investors i know the model of aircraft ideas, and other things. please let us make a team [email protected] and umdolmal [email protected]

- Roger Port said on November 25, 2019 I've been trying to get $10 mill funding for a startup here in the U.S., preferably the majority ($7-8 mil) and the rest from banks ($2-3 mil). We currently have 4 prototypes built that fly, and are certified by the F.A.A. We have almost everything needed to start, except the capital to start. Any help would be appreciated. [email protected]

- Ed Rij said on September 23, 2020 Roger, Have you had any luck in finding funding for your prototypes? Send me some information on your aircraft.

- Malik said on July 12, 2023 I'm planning to have a company..so we need a team... Then we can look for funds. My WhatsApp is +63 905 455 5570. Email: [email protected]

- Mr. MerMan said on December 18, 2023 All you guys talking about manufacturing aircraft without any money are stupid

- Franchise Opportunities

- Wholesale Business Opportunities

- Small Manufacturing Business

- Farming Business Ideas

- Unique Business Opportunities

- Shop Business Ideas

- Small Business Opportunities

- Startup Company Ideas

- Home Based Business Opportunity

- Rural Business Opportunities

- Tips for Buying and Selling

- Starting Rental Business

- Ideas for Small Business

- Free Business Ideas

- Internet Business Ideas

- Store Business Opportunities

- Entrepreneur Business Idea

- Retail Store Ideas

- Service Business Ideas

- Advice for Small Business

- Financing a Small Business

- Restaurant Business Opportunities

- Small Business Articles

- Business Marketing and Advertising

- Repair Business Opportunity

- Professional Career Opportunities

- Business Insurance Information

- Instructor Guides

Popular Articles

- About Pharmaceutical Manufacturing Business

- Starting a Plastic Manufacturing Plant

- Becoming a Brick Manufacturer

- Setting up an Animal Feed Manufacturing Company

- Starting a Garment Manufacturing Business

- Startup Guide for Chemical Manufacturing Business

- Starting Tobacco Product Manufacturing Company

- Glass Manufacturing Business

- Start Diaper Manufacturing Business

- Top 5 Money Making Manufacturing Businesses to Start in South Africa

How to create a financial forecast for an aircraft equipment maker?

Creating a financial forecast for your aircraft equipment manufacturing business, and ensuring it stays up to date, is the only way to maintain visibility on future cash flows.

This might sound complex, but with the right guidance and tools, creating an accurate financial forecast for your aircraft equipment manufacturing business is not that hard.

In this guide, we'll cover everything from the main goal of a financial projection, the data you need as input, to the tables that compose it, and the tools that can help you build a forecast efficiently.

Without further ado, let us begin!

In this guide:

Why create and maintain a financial forecast for an aircraft equipment manufacturing business?

- What information is used as input to build an aircraft equipment manufacturing business financial forecast?

The sales forecast for an aircraft equipment manufacturing business

The operating expenses for an aircraft equipment manufacturing business.

- What investments are needed for an aircraft equipment manufacturing business?

The financing plan of your aircraft equipment manufacturing business

What tables compose the financial plan for an aircraft equipment manufacturing business.

- Which tool should you use to create and maintain your aircraft equipment manufacturing business's financial projections?

- Financial forecast template for an aircraft equipment manufacturing business

The financial projections for your aircraft equipment manufacturing business act as a financial blueprint to guide its growth with confidence and ensure its long-term financial viability.

To create them, you will need to look at your business in detail - from sales to operating costs and investments - to assess how much profit it can generate in the years to come and what will be the associated cash flows.

During challenging market conditions, maintaining an up-to-date financial forecast enables early detection of potential financial shortfalls, allowing for timely adjustments or securing financing before facing a cash crisis.

Your aircraft equipment manufacturing business's financial forecast will also prove invaluable when seeking financing. Banks and investors will undoubtedly request a thorough examination of your financial figures, making precision and presentation essential.

Need a solid financial forecast?

The Business Plan Shop does the maths for you. Simply enter your revenues, costs and investments. Click save and our online tool builds a three-way forecast for you instantly.

What information is needed to build an aircraft equipment manufacturing business financial forecast?

The quality of your inputs is key when it comes to financial modelling: no matter how good the model is, if your inputs are off, so will the forecast.

If you are building a financial plan to start an aircraft equipment manufacturing business, you will need to have done your market research and have a clear picture of your sales and marketing strategies so that you can project revenues with confidence.

You will also need to have a clear idea of what resources will be required to operate the aircraft equipment manufacturing business on a daily basis, and to have done your research with regard to the equipment needed to launch your venture (see further down this guide).

If you are creating a financial forecast of an existing aircraft equipment manufacturing business, things are usually simpler as you will be able to use your historical accounting data as a budgeting base, and complement that with your team’s view on what lies ahead for the years to come.

Let's now zoom in on what will go in your aircraft equipment manufacturing business's financial forecast.

The sales forecast, also called topline projection, is normally where you will start when building your aircraft equipment manufacturing business financial forecast.

Creating a coherent sales projection boils down to estimating two key drivers:

- The average price

- The number of monthly transactions

To do this, you will need to rely on historical data (for an existing business), market research data (for both new and existing aircraft equipment makers), and consider the elements below:

- Economic conditions: Changes in the overall economy can impact the demand for aircraft equipment. If the economy is doing well, there may be higher demand for new aircraft, which could lead to an increase in demand for your equipment and therefore a higher average price or number of monthly transactions.

- Technological advancements: As technology continues to advance, newer and more efficient equipment may become available in the market. This could lead to a decrease in demand for your current equipment and a decrease in your average price or number of monthly transactions as customers opt for newer options.

- Competition: The presence of competitors in the market can affect your average price and number of monthly transactions. If there are many competitors offering similar equipment at lower prices, you may need to lower your prices to remain competitive, which could impact your average price and number of transactions.

- Regulatory changes: Changes in regulations related to aircraft equipment could impact the demand for your products. For example, stricter safety regulations may require airlines to upgrade their equipment, leading to higher demand and potentially higher prices for your products.

- Global events: Global events such as natural disasters or political instability can have a significant impact on the aviation industry. If there is a decrease in air travel due to these events, there may be a decrease in demand for aircraft equipment, resulting in lower average prices and number of transactions for your business.

After the sales forecast comes the operating expenses budget, which we will now look into in more detail.

Need inspiration for your business plan?

The Business Plan Shop has dozens of business plan templates that you can use to get a clear idea of what a complete business plan looks like.

Once you know what level of sales you can expect, you can start budgeting the expenses required to operate your aircraft equipment manufacturing business on a daily basis.

Expenses normally vary based on how much revenue you anticipate (which is why, from experience, it is always better to start your forecast with the topline projection), and where your business is based.

Operating expenses for an aircraft equipment manufacturing business will include some of the following items:

- Staff Costs: This includes salaries, wages, benefits, and any other expenses related to your employees. For an aircraft equipment manufacturing business, this may also include specialized training for your staff.

- Accountancy Fees: You will need to hire an accountant or accounting firm to help you manage your financials, file taxes, and ensure compliance with regulations specific to the aviation industry.

- Insurance Costs: As an aircraft equipment manufacturer, you will need to invest in insurance to protect your business from potential liabilities and damages.

- Software Licenses: To streamline your operations and improve efficiency, you may need to purchase software for various functions such as inventory management, accounting, and project management.

- Banking Fees: You will incur fees for various banking services such as wire transfers, credit card processing, and account maintenance.

- Raw Materials: This includes the cost of purchasing materials and components needed to manufacture your aircraft equipment.

- Manufacturing Equipment Maintenance: You will need to regularly maintain and repair your manufacturing equipment to ensure it is functioning properly and to avoid any production delays.

- Research and Development: As a manufacturer, you will need to continuously invest in research and development to improve your products and stay ahead of competitors.

- Marketing and Advertising: To promote your business and attract clients, you may need to invest in marketing and advertising efforts such as trade shows, print ads, and digital campaigns.

- Shipping and Freight: As an aircraft equipment manufacturer, you may need to ship your products to clients or suppliers, which will incur costs for packaging, transportation, and customs fees.

- Utilities: This includes expenses for electricity, water, and other utilities needed to run your manufacturing facility.

- Rent/Lease: You may need to rent or lease a manufacturing facility, warehouse, or office space to operate your business.

- Professional Services: You may need to hire lawyers, consultants, or other professionals for specific projects or to assist with legal and regulatory compliance.

- Travel Expenses: If you need to travel for business purposes, you will need to budget for expenses such as airfare, accommodations, and meals.

- Taxes and Licenses: As a business owner, you will need to pay taxes and obtain necessary licenses and permits to operate your aircraft equipment manufacturing business.

This list will need to be tailored to the specificities of your aircraft equipment manufacturing business, but should offer a good starting point for your budget.

What investments are needed to start or grow an aircraft equipment manufacturing business?

Your aircraft equipment manufacturing business financial forecast will also need to include the capital expenditures (aka investments in plain English) and initial working capital items required for the creation or development of your business.

For an aircraft equipment manufacturing business, these could include:

- Manufacturing Equipment: This includes the purchase of machinery and equipment used in the production process of aircraft equipment, such as cutting machines, welding equipment, and testing equipment.

- Research and Development: As an aircraft equipment manufacturing business, it is important to continuously innovate and improve your products. This may require investments in research and development, such as new software or specialized equipment.

- Facility Upgrades: In order to maintain a safe and efficient manufacturing environment, you may need to invest in upgrades or renovations to your facility. This could include installing new ventilation or lighting systems, upgrading electrical wiring, or expanding your production space.

- Inventory: As an aircraft equipment manufacturer, you will need to keep a large inventory of parts and materials on hand to meet demand and fulfill orders. This may require significant upfront investments in inventory, which will be gradually recouped through sales.

- Transportation and Delivery Vehicles: In order to deliver your products to clients, you may need to invest in specialized vehicles, such as trucks or vans, equipped with the necessary equipment to transport aircraft equipment safely and efficiently.

Again, this list will need to be adjusted according to the size and ambitions of your aircraft equipment manufacturing business.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast to assess the potential profitability of your projects, and write a business plan that’ll wow investors.

The next step in the creation of your financial forecast for your aircraft equipment manufacturing business is to think about how you might finance your business.

You will have to assess how much capital will come from shareholders (equity) and how much can be secured through banks.

Bank loans will have to be modelled so that you can separate the interest expenses from the repayments of principal, and include all this data in your forecast.

Issuing share capital and obtaining a bank loan are two of the most common ways that entrepreneurs finance their businesses.

Now let's have a look at the main output tables of your aircraft equipment manufacturing business's financial forecast.

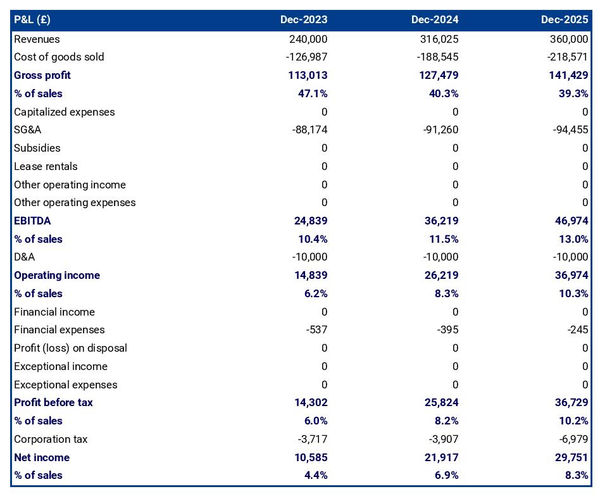

The projected profit & loss statement

The projected profit & loss shows how profitable your aircraft equipment manufacturing business is likely to be in the years to come.

For your aircraft equipment manufacturing business to be financially viable, your projected P&L should ideally show:

- Sales growing above inflation (the higher the better)

- Profit margins which are stable or expanding (the higher the better)

- A net profit at the end of each financial year (the higher the better)

This is for established aircraft equipment makers, there is some leniency for startups which will have numbers that will look a bit different than existing businesses.

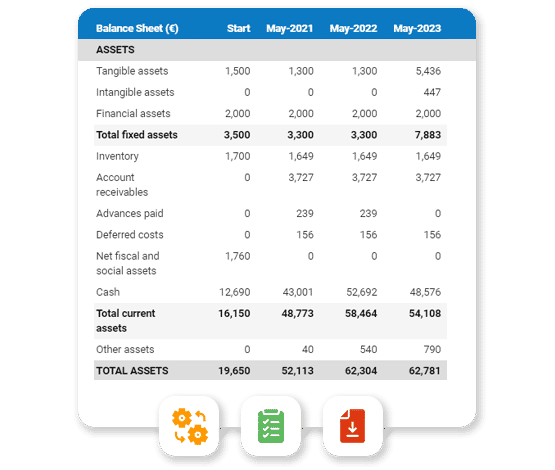

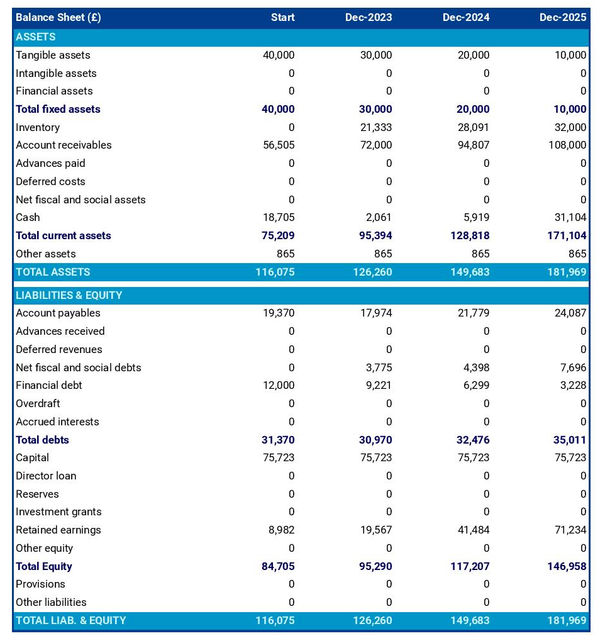

The projected balance sheet

The projected balance sheet gives an overview of your aircraft equipment manufacturing business's financial structure at the end of the financial year.

It is composed of three categories of items: assets, liabilities and equity:

- Assets: are what the business possesses and uses to produce cash flows. It includes resources such as cash, buildings, equipment, and accounts receivable (money owed by clients).

- Liabilities: are the debts of your aircraft equipment manufacturing business. They include accounts payable (money owed to suppliers), taxes due and bank loans.

- Equity: is the combination of what has been invested by the business owners and the cumulative profits to date (which are called retained earnings). Equity is a proxy for the value of the owner's stake in the business.

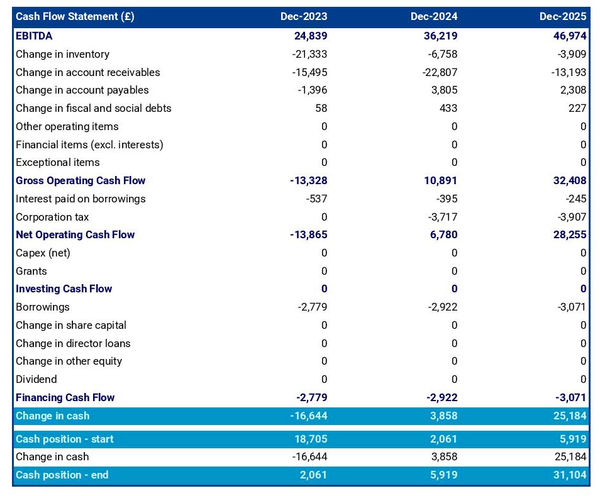

The projected cash flow statement

A projected cash flow statement for an aircraft equipment manufacturing business is used to show how much cash the business is generating or consuming.

The cash flow forecast is usually organised by nature to show three key metrics:

- The operating cash flow: do the core business activities generate or consume cash?

- The investing cash flow: how much is the business investing in long-term assets (this is usually compared to the level of fixed assets on the balance sheet to assess whether the business is regularly maintaining and renewing its equipment)?

- The financing cash flow: is the business raising new financing or repaying financiers (debt repayment, dividends)?

Cash is king and keeping an eye on future cash flows is imperative for running a successful business. Therefore, you should pay close attention to your aircraft equipment manufacturing business's cash flow forecast.

If you are trying to secure financing, note that it is customary to provide both yearly and monthly cash flow forecasts in a financial plan - so that the reader can analyze seasonal variation and ensure the aircraft equipment manufacturing business is appropriately capitalised.

Which tool should you use to create your aircraft equipment manufacturing business's financial forecast?

Using the right tool or solution will make the creation of your aircraft equipment manufacturing business's financial forecast much easier than it sounds. Let’s explore the main options.

Using online financial forecasting software to build your aircraft equipment manufacturing business's projections

The modern and easiest way is to use an online financial forecasting tool such as the one we offer at The Business Plan Shop.

There are several advantages to using specialised software:

- You can easily create your financial forecast by letting the software take care of the financial calculations for you without errors

- You have access to complete financial forecast templates

- You get a complete financial forecast ready to be sent to your bank or investors

- You can easily track your actual financial performance against your financial forecast, and recalibrate your forecast as the year goes by

- You can create scenarios to stress test your forecast's main assumptions

- You can easily update your forecast as time goes by to maintain visibility on future cash flows

- You have a friendly support team on standby to assist you when you are stuck

- It’s cost-efficient and much cheaper than using an accountant or consultant (see below)

If you are interested in this type of solution, you can try our projection software for free by signing up here .

Calling in a financial consultant or chartered accountant

Outsourcing the creation of your aircraft equipment manufacturing business financial forecast is another possible solution.

This will cost more than using software as you can expect as your price will have to cover the accountant’s time, software cost, and profit margin.

Price can vary greatly based on the complexity of your business. For a small business, from experience, a simple three-year financial forecast (including a balance sheet, income statement, and cash flow statement) will start at around £700 or $1,000.

Bear in mind that this is for forecasts produced at a single point in time, updating or tracking your forecast against actuals will cost extra.

If you decide to outsource your forecasting:

- Make sure the professional has direct experience in your industry and is able to challenge your assumptions constructively.

- Steer away from consultants using sectorial ratios to build their client’s financial forecasts (these projections are worthless for a small business).

Why not use a spreadsheet such as Excel or Google Sheets to build your aircraft equipment manufacturing business's financial forecast?

You and your financial partners need numbers you can trust. Unless you have studied finance or accounting, creating a trustworthy and error-free aircraft equipment manufacturing business financial forecast on a spreadsheet is likely to prove challenging.

Financial modelling is very technical by nature and requires a solid grasp of accounting principles to be done without errors. This means that using spreadsheet software like Excel or Google Sheets to create accurate financial forecasts is out of reach for most business owners.

Creating forecasts in Excel is also inefficient nowadays:

- Software has advanced to the point where forecasting can be done much faster and more accurately than manually on a spreadsheet.

- With artificial intelligence, the software is capable of detecting mistakes and helping decision-making.

Spreadsheets are versatile tools but they are not tailor-made for reporting. Importing your aircraft equipment manufacturing business's accounting data in Excel to track actual vs. forecast is incredibly manual and tedious (and so is keeping forecasts up to date). It is much faster to use dedicated financial planning tools like The Business Plan Shop which are built specially for this.

Use our financial forecast templates for inspiration

The Business Plan Shop has dozens of financial forecast examples available.

Our templates contain both a financial forecast and a written business plan which presents, in detail, the company, the team, the strategy, and the medium-term objectives.

Our templates are a great source of inspiration, whether you just want to see what a complete business plan looks like, or are looking for concrete examples of how you should model financial elements in your own forecast.

- Having a financial forecast enables you to visualise the expected growth, profitability, and cash generation for your business over the next three to five years.

- Tracking actuals vs. forecast and keeping your financial projections up-to-date is the only way to get a view on what your aircraft equipment manufacturing business future cash flows may look like.

- Using financial forecasting software is the mordern and easy way to create and maintain your forecasts.

This is the end of our guide on how to build the financial forecast for an aircraft equipment manufacturing business, we hope you found it useful. Don't hesitate to contact us if you want to share your feedback or have any questions.

Also on The Business Plan Shop

- Example of financial forecast

Know someone who owns or is thinking of starting an aircraft equipment manufacturing business? Share our forecasting guide with them!

Founder & CEO at The Business Plan Shop Ltd

Guillaume Le Brouster is a seasoned entrepreneur and financier.

Guillaume has been an entrepreneur for more than a decade and has first-hand experience of starting, running, and growing a successful business.

Prior to being a business owner, Guillaume worked in investment banking and private equity, where he spent most of his time creating complex financial forecasts, writing business plans, and analysing financial statements to make financing and investment decisions.

Guillaume holds a Master's Degree in Finance from ESCP Business School and a Bachelor of Science in Business & Management from Paris Dauphine University.

Create a convincing business plan

Assess the profitability of your business idea and create a persuasive business plan to pitch to investors

500,000+ entrepreneurs have already tried our solution - why not join them?

Not ready to try our on-line tool ? Learn more about our solution here

Need some inspiration for your business plan?

Subscribe to The Business Plan Shop and gain access to our business plan template library.

Need a professional business plan? Discover our solution

Write your business plan with ease!

It's easy to create a professional business plan with The Business Plan Shop

Want to find out more before you try? Learn more about our solution here

What are you looking for?

Most popular topics.

- Sustainable Aviation Fuel (SAF)

The life cycle of an aircraft

Airbus has built more than 13,500 commercial aircraft during the company’s 50-plus year history, maintaining a leadership position through a focus on innovation, performance and efficiency.

A proven international system

The production of Airbus aircraft benefits from a truly international industrial system with cooperation across the company’s global footprint, partnered with a worldwide supply chain. Airbus has evolved how its airplanes are built. New digital technologies help to deliver on time while maintaining quality, keep flexibility to adjust aircraft production, and reduce the impact of manufacturing activities on the environment for improved sustainability.